Wheat and maize double-functional seeder

A dual-function, seeder technology, applied in the field of seeders, can solve problems such as the inability of seeding equipment to work, and achieve the effect of reducing the investment of agricultural machinery and equipment and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

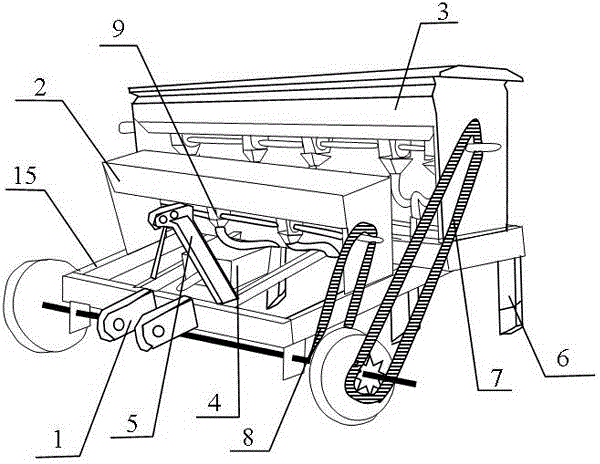

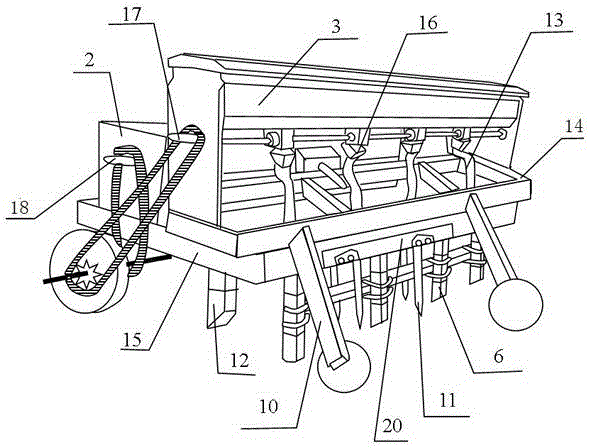

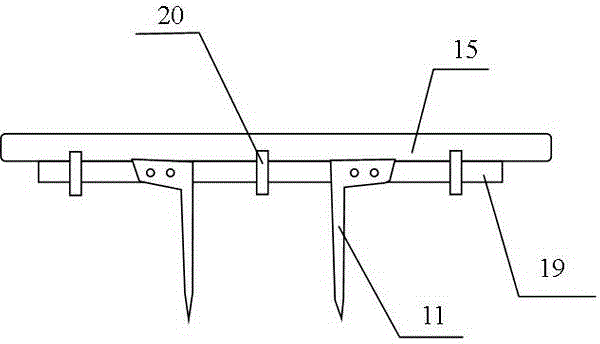

[0019] Such as figure 1 , 2 , a kind of wheat corn dual-function planter shown in 3, comprises the frame that has suspension head 1, is installed in the transmission shaft on the frame below suspension head, is installed in the walking wheel of transmission shaft two ends, is installed on the frame The seeding box 3, the fertilization box 2, the sowing mechanism and the fertilization mechanism connected with the seeding box and the fertilization box, and the soil covering mechanism 10 installed at the rear of the frame; it is characterized in that: it also includes a frame mounted on the frame near the suspension head 1 The grass-moving transmission mechanism 4 is installed on the frame and is positioned at the grass-moving mechanism at the rear of the frame. The grass-moving transmission mechanism 4 is connected to the grass-moving mechanism, and the described sowing mechanism and the fertilization mechanism are connected to the drive shaft; the described grass-moving mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com