A valveless liquid-liquid extraction device

An extraction device and valveless technology, applied in the field of chemical equipment, can solve the problems of few simple structure extraction and sufficient extraction devices, difficult method development, high price, etc., and achieves the effects of economy and practicality, high extraction and separation efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

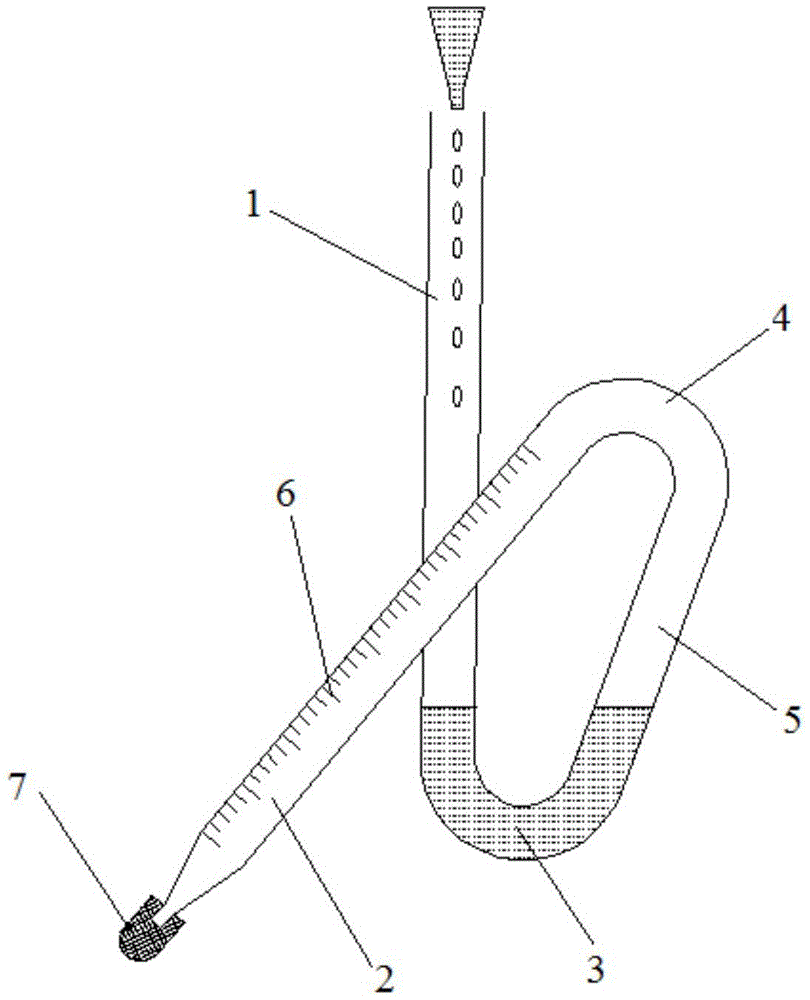

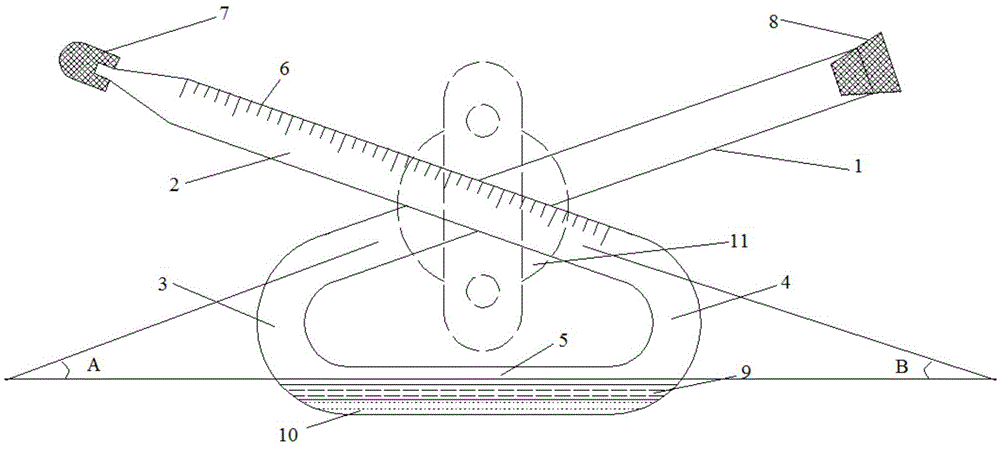

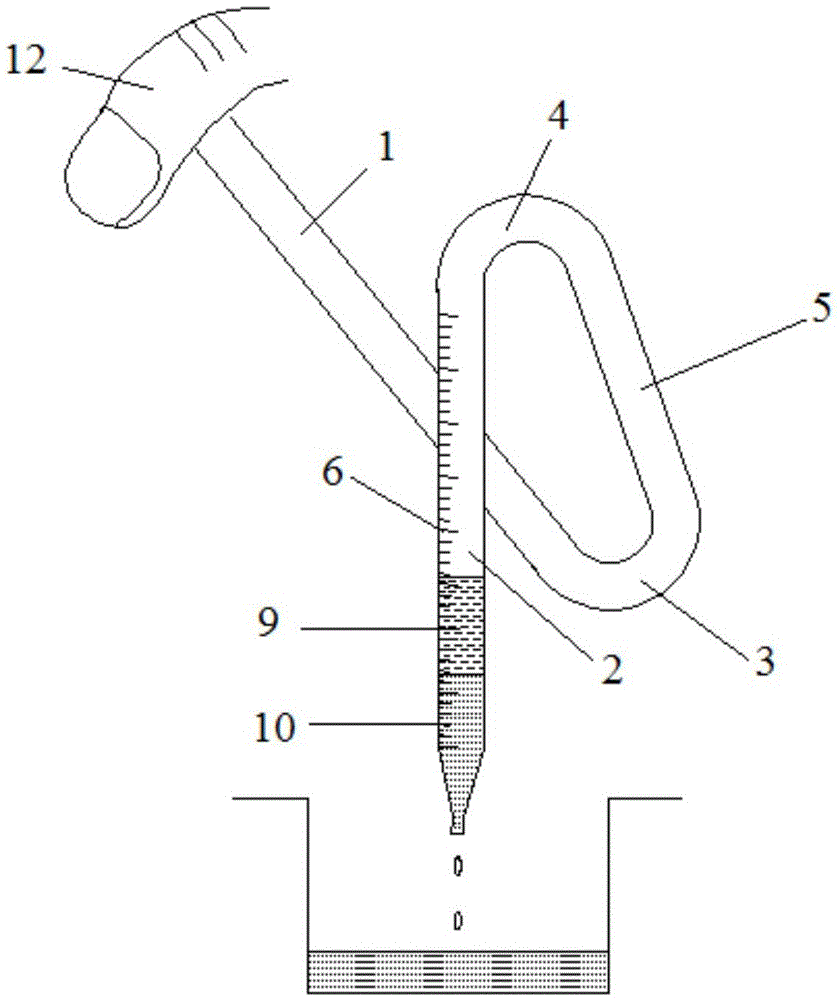

[0031] Such as Figure 1-3 As shown, a valveless liquid-liquid extraction device includes a glass tube with both ends bent inward and a rotatable clamp 11 for fixing the glass tube on the vibrator. One end of the glass tube is used for adding liquid end 1, and the other end is a liquid discharge end 2 with a scale, and the liquid filling end 1 and the liquid discharge end 2 are also provided with rubber plugs and rubber sealing caps respectively.

[0032] Wherein, both the liquid-filling end 1 and the liquid-discharging end 2 are bent inwardly to form a first bending angle 3 and a second bending angle 4 respectively, and the first bending angle 3 and the second bending angle 4 are formed between the first bending angle 3 and the second bending angle 4 for The middle section pipeline 5 that accommodates the liquid sample and the organic solvent for extraction. Both the first bending angle 3 and the second bending angle 4 are arc bending angles, the rubber sealing cap 7 is a si...

Embodiment 2

[0037] In this embodiment, the angle A between the liquid feeding end and the middle pipe is 30°, the angle B between the liquid discharge end and the middle pipe is 30°, and the rest are the same as in Embodiment 1.

Embodiment 3

[0039] In this embodiment, the angle A between the liquid feeding end and the middle pipe is 25°, the angle B between the liquid discharge end and the middle pipe is 25°, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com