Ring Die Granulator Equal Thickness Auxiliary Device

A ring die granulation, equal thickness technology, applied in the direction of die extrusion granulation, etc., can solve the problems of increased vibration amplitude, large change of extrusion force, production interruption, etc., to avoid machine blockage, increase distance, and solve time. The effect of the delay feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

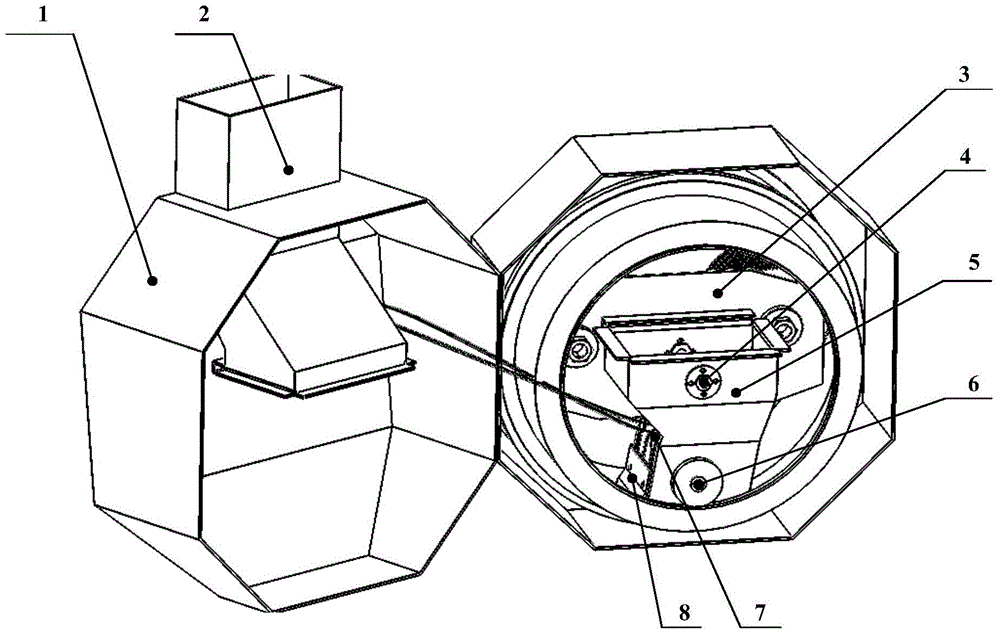

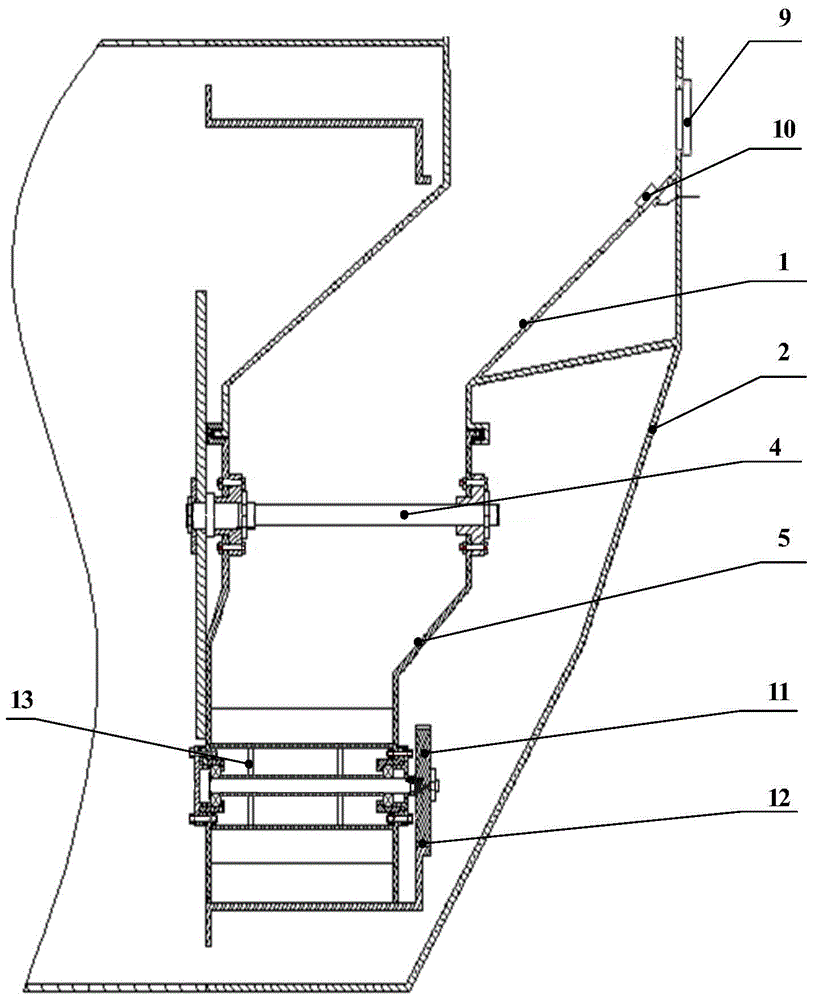

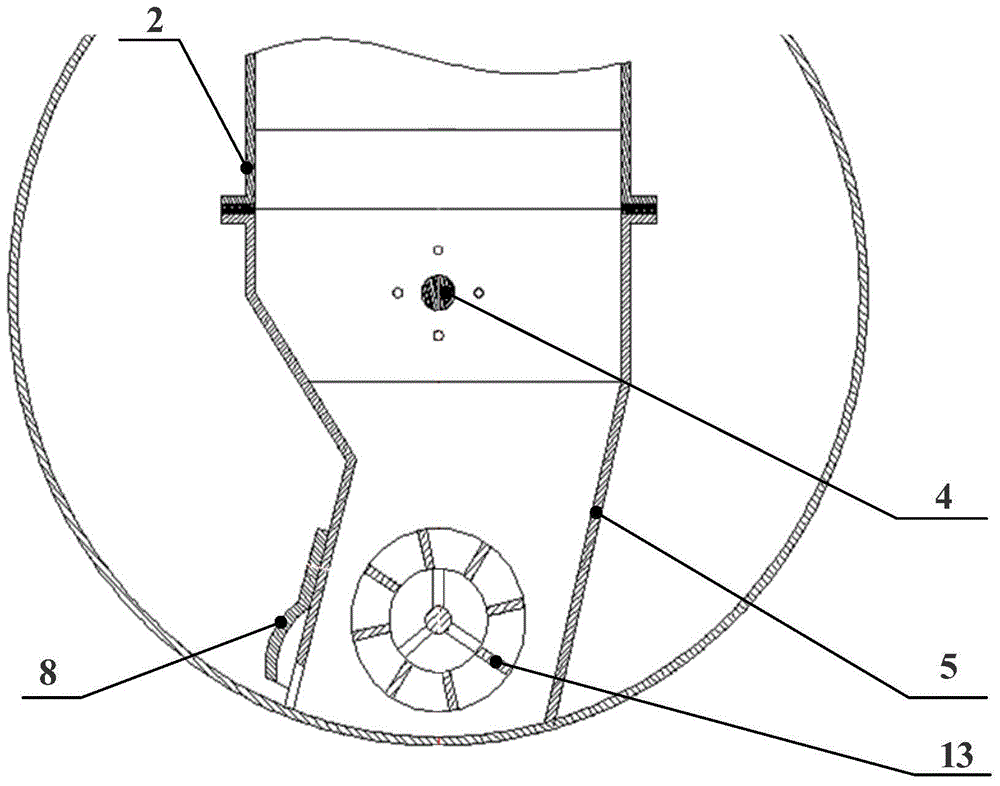

[0025] A constant-thickness auxiliary feeder for a ring die granulator, comprising a hopper assembly, an impeller assembly, a support assembly and a scraper assembly. The hopper assembly includes an upper hopper shell 1, an upper hopper powder channel 2, a lower hopper 5, a see-through window glass cover 9, and a lighting lamp 10; the impeller assembly includes an impeller shaft 6, a timing pulley 11, a timing belt 12, and an impeller 13; The assembly includes a support plate 3 and a support shaft 4; the scraper assembly includes a rope pulley lifter 7 and a scraper 8;

[0026] The shell 1 of the upper hopper is hinged with the shell of the granulator. The powder channel 2 of the upper hopper is an oblique channel. The bottom of the powder channel 2 of the upper hopper matches the opening size of the top of the lower hopper 5. Inside the material ring, the lower hopper 5 is fixed on the support plate 3 through the support shaft 4, the support plate 3 is fixed on the pressure r...

Embodiment 2

[0030] An equal-thickness auxiliary feeder for a ring die granulator, comprising an upper hopper shell 1, an upper hopper powder passage 2, a support plate 3, a lower hopper 5, an impeller shaft 6, a rope wheel lifter 7, a scraper 8, and a timing belt Wheel 11, synchronous belt 12, impeller 13.

[0031]The shell of the upper hopper 1 is hinged with the shell of the ring die granulator. The powder channel 2 of the upper hopper is an oblique channel. The bottom opening of the powder channel 2 of the upper hopper matches the opening size of the top opening of the lower hopper 5. The top of the hopper 5 is fixed and sealed. The lower hopper 5 is set inside the blanking ring of the ring die granulator. The lower hopper 5 is fixed on the support plate 3. The opening at the bottom of the lower hopper 5 is facing the bottom of the blanking ring of the ring die granulator. The inner surface, and the opening at the bottom of the lower hopper 5 is kept at a distance of 2 mm from the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com