A brake disc surface automatic spraying and coating curing induction heating equipment

An induction heating equipment and automatic spraying technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of low production efficiency, high energy consumption of the production line, and small equipment input-output ratio , achieve the effects of saving labor costs, improving spraying efficiency, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

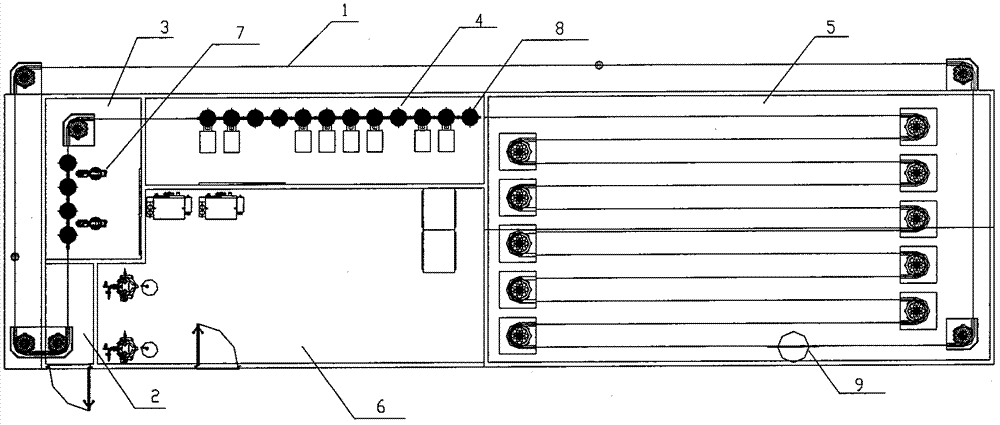

[0017] Such as Figure 1-Figure 5 As shown, the present invention includes a conveyor belt 1 , a purge chamber 2 , a paint spray chamber 3 , an induction heating chamber 4 , a cooling chamber 5 and a control chamber 6 . Multiple high-power blowers are set in the purge room 2; multiple spraying equipment 7 are set in the paint spraying room 3; induction heating equipment 8 is set in the induction heating room; cooling equipment 9 is set in the cooling room 5. The controller provided in the control room 6 is used to control the operation of the conveyor belt 1 and to monitor other workshops in real time. The conveyor belt 1 is sequentially connected to the purge chamber 2, the paint spray chamber 3, the induction heating chamber 4 and the cooling chamber 5 through the conveying wheels to form an operating system together.

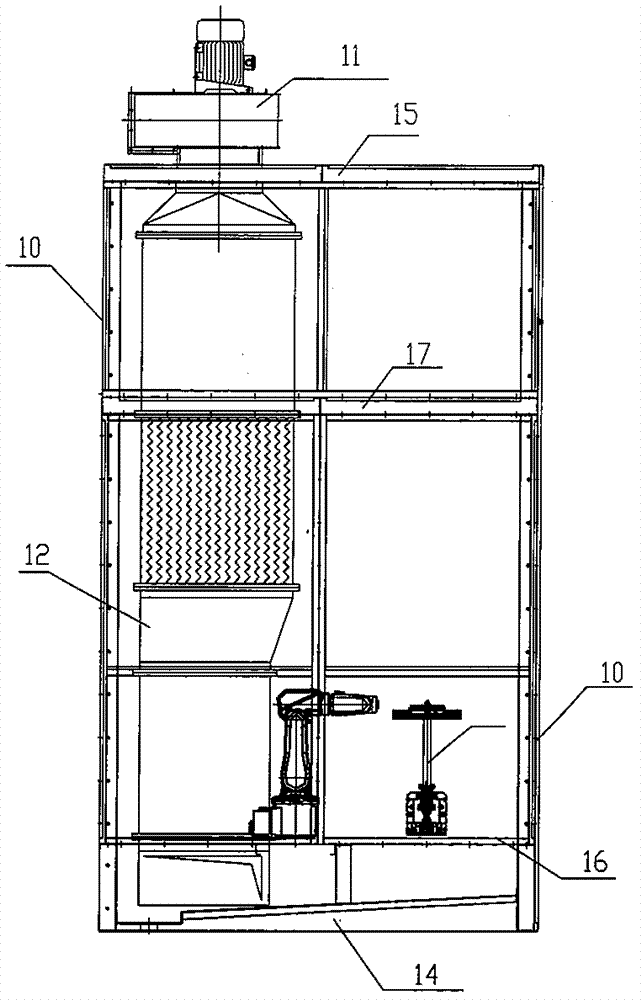

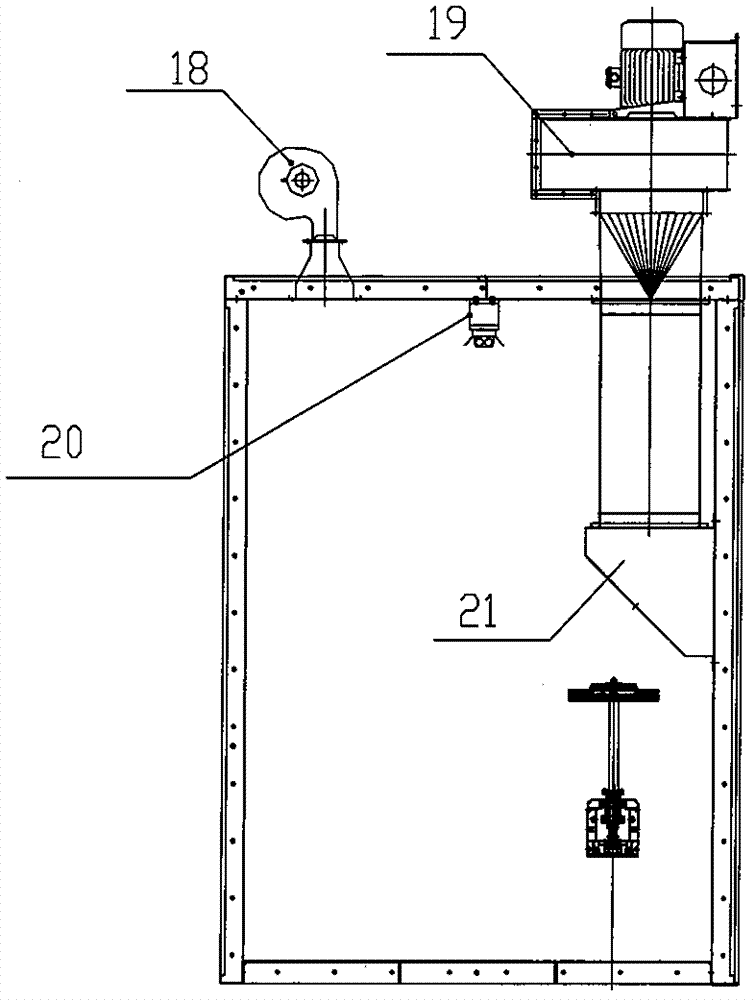

[0018] The spraying equipment includes a side wall plate 10 , a spray booth exhaust fan 11 , an air duct 12 , a stainless steel water tank 14 , an upper wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com