Silencer inner core press-mounting device use method

A press-fit device and muffler technology, applied in the field of press-fit machines, can solve problems such as failure of the inner core press-fit, cracks in the muffler cylinder, and looseness in the fixation of the muffler cylinder, so as to avoid deflection displacement or radial runout, reduce Impact damage rate and the effect of improving press-fitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

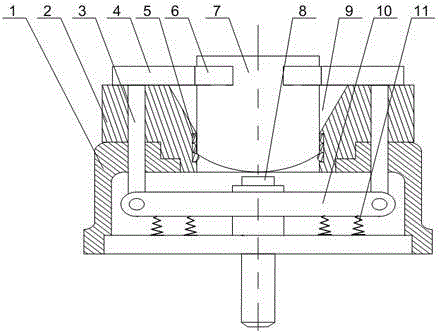

[0023] Such as figure 1 As shown, this embodiment includes the following steps:

[0024] (A) Place the muffler cylinder in the conical cavity until the outer wall of the muffler cylinder is in contact with the inner wall of the through hole. At this time, the driving device is activated to make the crossbar start to move downward, and the chuck at the end of the fixed plate is Directly hug the outer wall of the muffler cylinder to move it along the axis of the fastener;

[0025] (B) The rubber ring is in direct contact with the outer wall of the muffler cylinder when it moves downwards to prevent the outer wall of the muffler cylinder from being hardly damaged. At the same time, when the pressing part acts on the inner core, the muffler cylinder can continue to drop in the through hole Move a certain distance, that is, buffer movement, until the bottom of the muffler cylinder contacts the upper end of the push rod, restrict the continued movement of the muffler cylinder, and ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com