3D printer

A technology of 3D printer and single-chip microcomputer, applied in the direction of additive processing, etc., can solve the problems of waste of raw materials, long time of large and complex products, and ineffective use of printing filaments, so as to avoid the waste of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

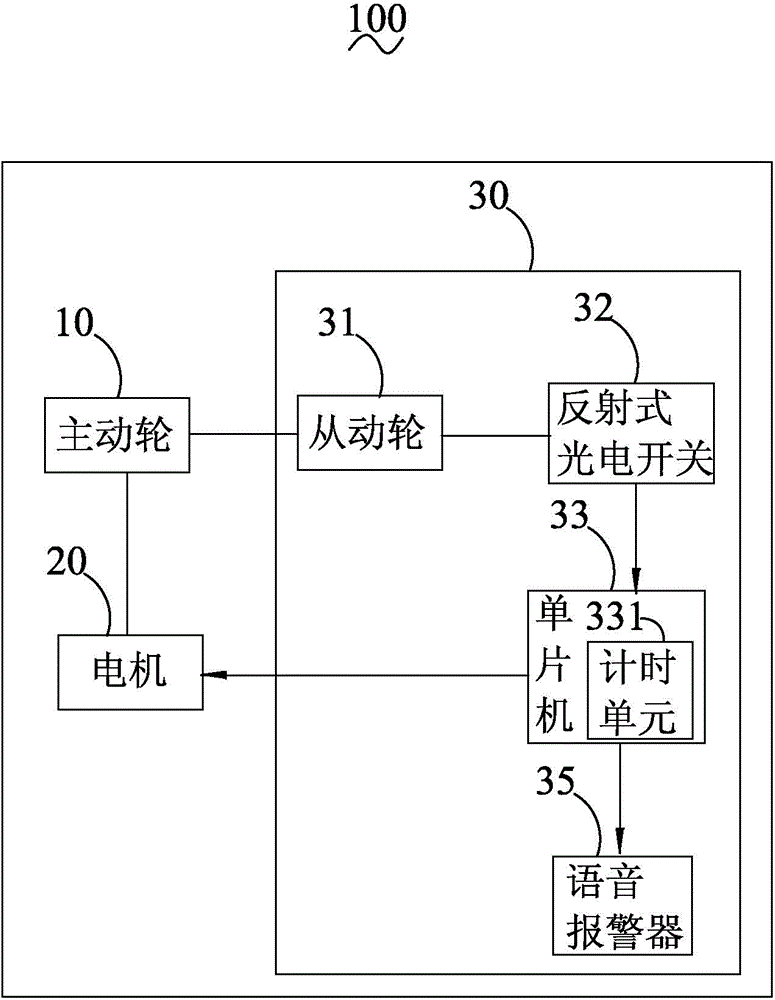

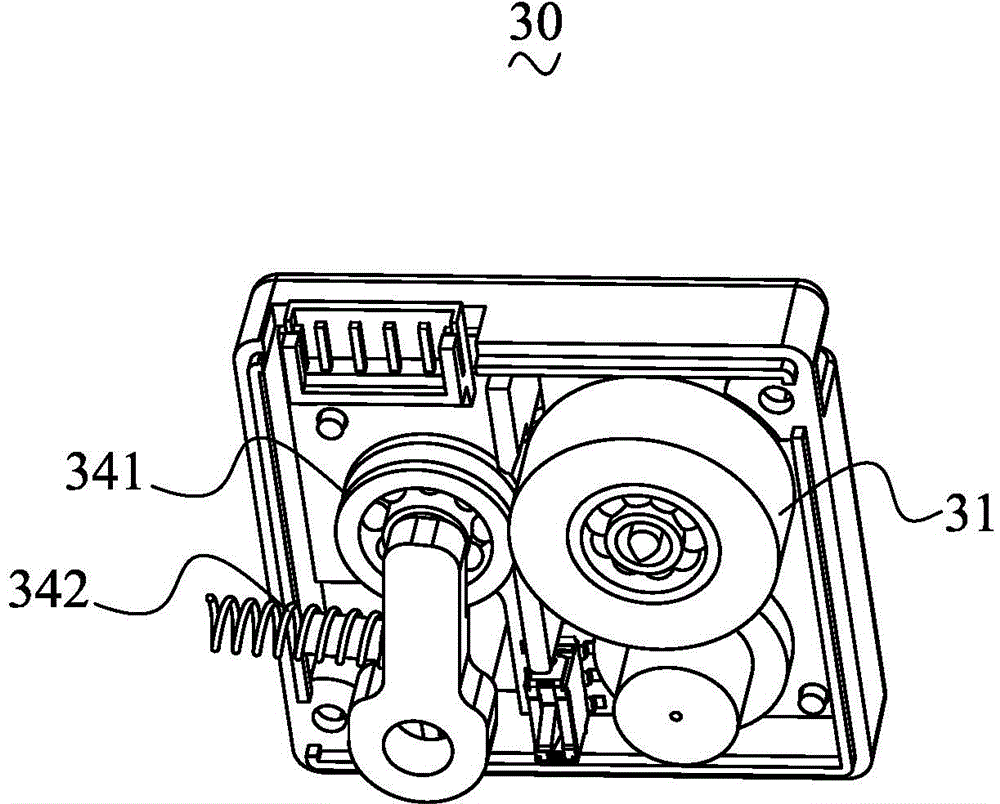

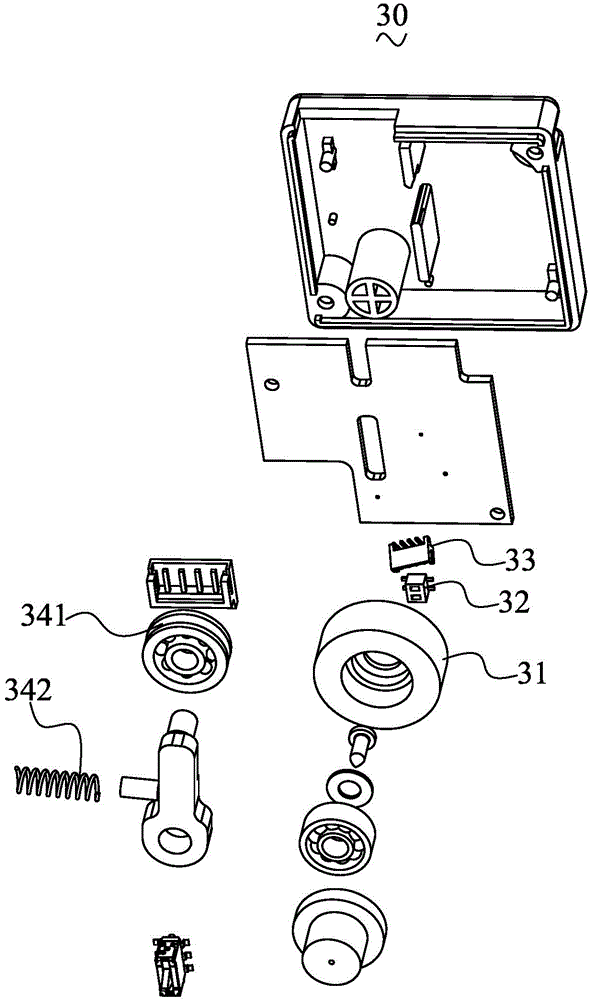

[0020] see figure 1 , which is a structural block diagram of a 3D printer 100 provided by the present invention. The 3D printer 100 includes a driving wheel 10 arranged along the moving direction of the printing filament produced by the 3D printer 100 , a motor 20 for driving the driving wheel 10 , and a wire blocking detection module 30 . It is conceivable that the 3D printer 100 may also include a frame for support, a nozzle for ejecting printing filaments, and corresponding line connection equipment, etc., which are existing technologies and are not the technology to be solved by the present invention. The key points of the problem will not be repeated here.

[0021] The drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com