Foldable turnover mesh belt and feeding and discharging system provided with turnover mesh belt

A folding, feeding and discharging technology, applied in the directions of transportation, packaging, conveyors, etc., can solve problems such as affecting the appearance design of the automatic feeding and discharging system, disturbing the airflow of the automatic feeding and discharging system, and inability to arbitrarily increase the overturned mesh belt to achieve the layout. Demand, avoid drug contamination, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

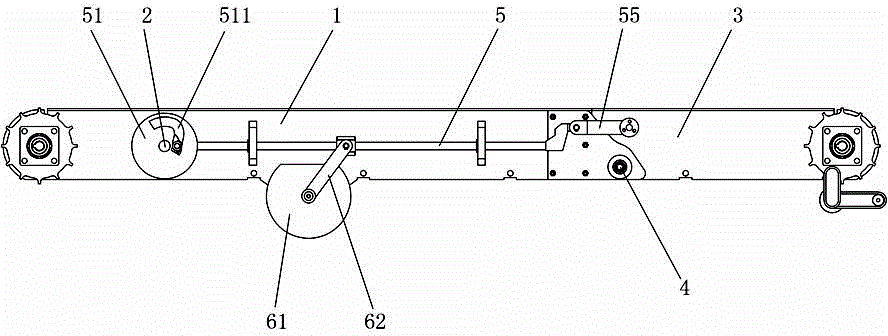

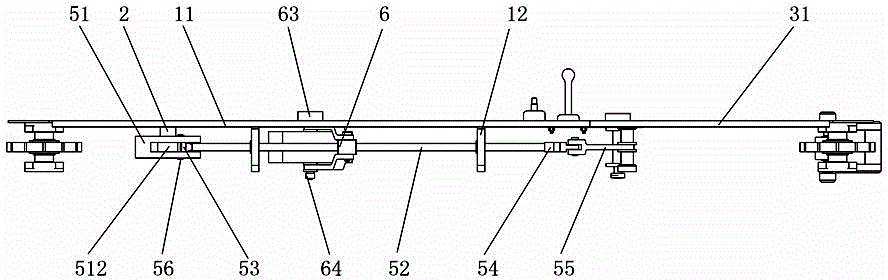

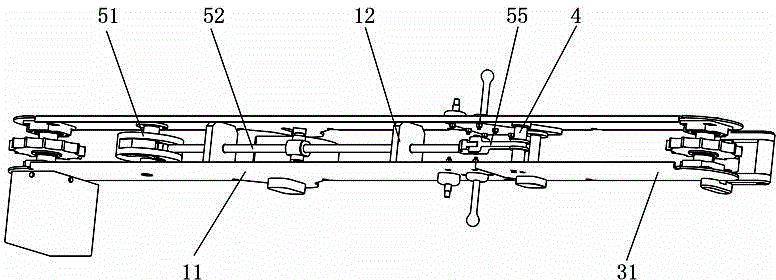

[0029] Figure 1 to Figure 4 Shown is a kind of embodiment of the foldable reversible net belt of the present invention, and this foldable reversible net belt comprises conveyer belt, first rotating shaft 2 and the reversing rack 1 that can rotate around first rotating shaft 2, and this foldable reversible net belt also Including the folding frame 3 and the folding drive device 5, the folding frame 3 is connected with the turning frame 1 and rotates relative to the turning frame 1, the conveyor belt is wound around the turning frame 1 and the folding frame 3, and the folding driving device 5 is synchronized when the turning frame 1 turns over The folding frame 3 is driven to rotate relative to the turning frame 1 . When the automatic feeding and discharging system works normally, the folding frame 3 and the turning frame 1 are locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com