Acoustic flowmeter and method for determining the flow in an object

An object and flow technology, applied in the measurement of flow/mass flow, fluid using vibration, liquid/fluid solid measurement, etc. High sensitivity and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Parts that function identically or similarly, where applicable, are provided with the same reference numerals. The individual technical features of the exemplary embodiments described below can likewise lead to improvements according to the invention together with the features of the previously described exemplary embodiments.

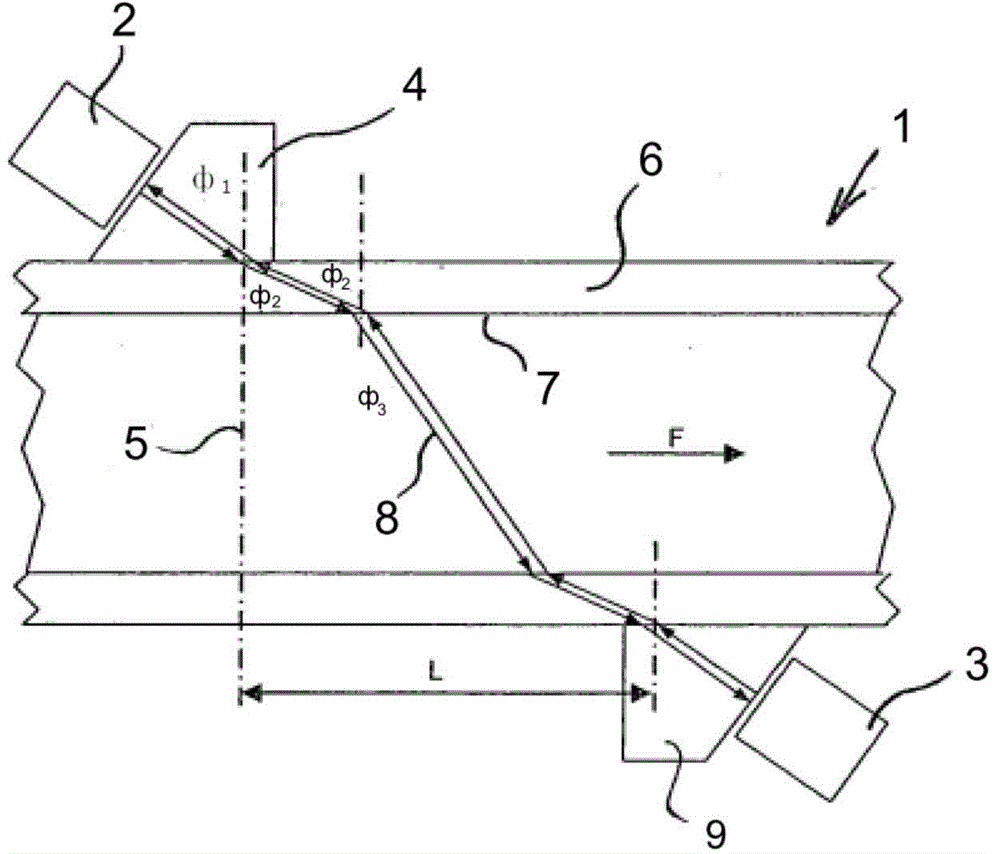

[0052] figure 1 A configuration known from the prior art for measuring the flow F of a medium, in particular a gas or a liquid, in a line 1 shown in section is shown. The piezoelectric ultrasonic transducer 2 can act like the piezoelectric ultrasonic transducer 3 not only as a transmitting transducer but also as a receiving transducer. Starting from, for example, the transmitting transducer 2, the ultrasonic signal passes through the wedge-shaped acoustic coupler 4 at an angle φ 1 (measured relative to the perpendicular 5 to the pipe surface) is coupled into the pipe wall 6 of the object. In the assumed situation that ultrasonic waves propaga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com