Method for electrically connecting a converter to an electrical machine

A technology of inverter and electrical connection, applied in the direction of motor generator control, motor generator/starter, starter of single multi-phase induction motor, etc., can solve problems such as high voltage, achieve torque impact reduction, mechanical Parts protection, smooth start-up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

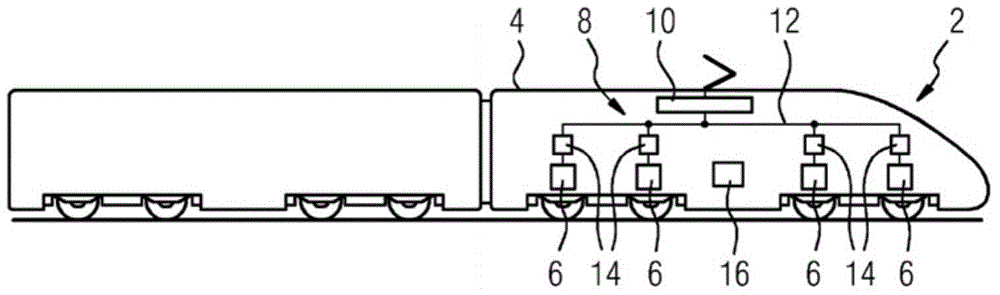

[0034] figure 1 A schematic diagram of a rail vehicle 2 is shown, which has a motor vehicle 4 with four driven axles. Each of the axles is driven by an electric motor 6 which is respectively configured as a synchronous engine and serves as a traction engine to drive the train. All traction engines 6 are fed by a traction inverter 8. The traction inverter 8 includes an input rectifier 10 that generates the intermediate circuit DC voltage in the intermediate circuit 12 from the grid voltage of the overhead line (via multiple stages if necessary).

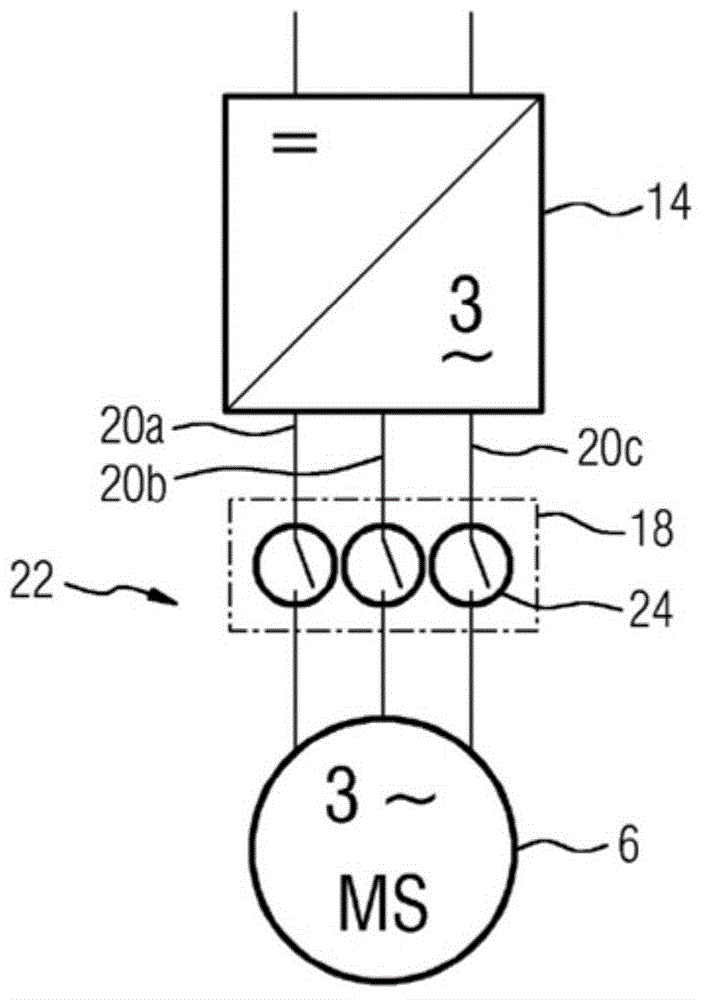

[0035] The four inverters 14 are electrically connected to the intermediate circuit 12. The inverters are configured as motor inverters in the form of pulse inverters in this embodiment, but other types of inverters can also be considered. The inverter 14 converts the intermediate circuit DC voltage into a three-phase AC voltage for the motor 6, wherein each of the inverters 4 supplies power to each motor 6. It is also possible that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com