Marine oil spill treatment agent spraying device

A technology of oil spill treatment and spraying device, which is applied in the direction of spraying device, etc., which can solve the problems of good spraying effect, small spraying range, and insufficient spraying, and achieve good spraying effect and wide spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

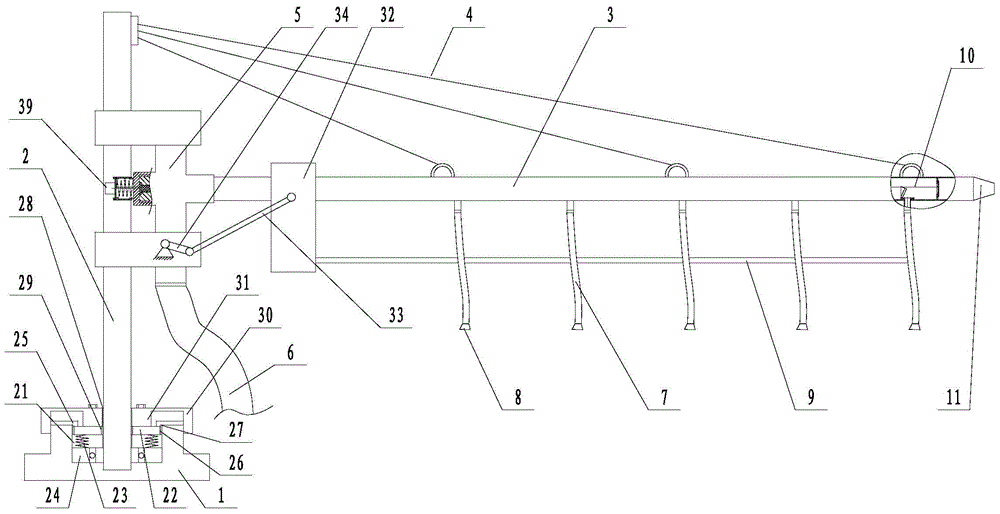

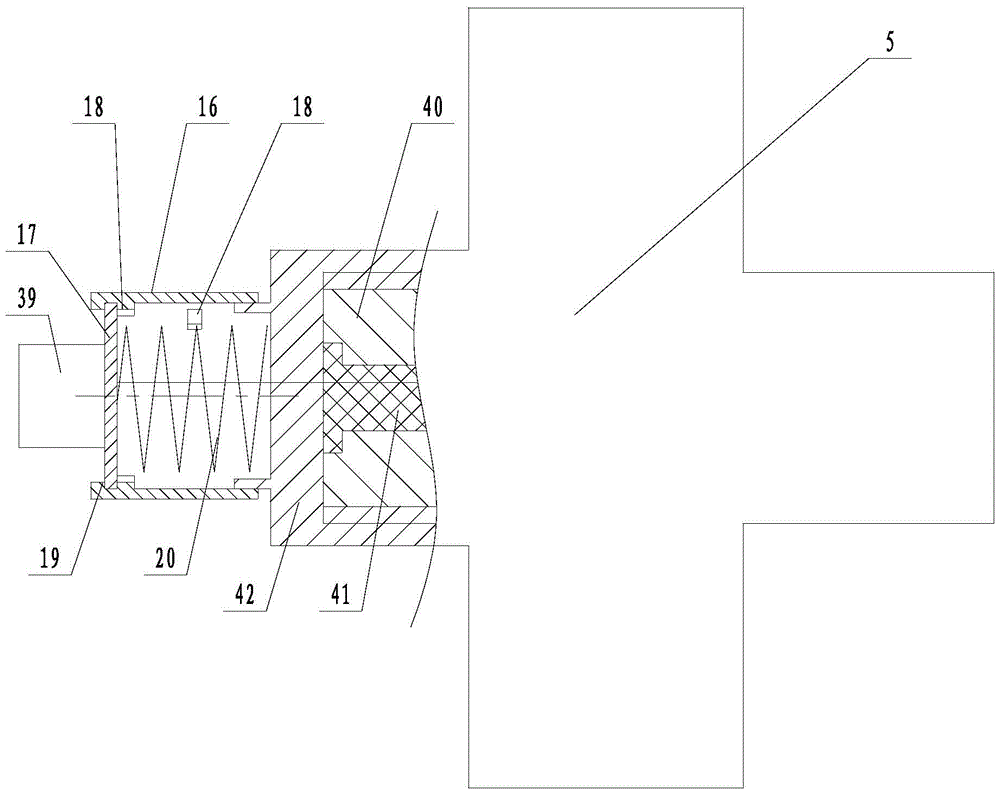

[0021] Embodiment 1: a kind of marine oil spill treatment agent spraying device (see attached figure 1 ), including a base 1, a pillar 2, and a cantilever nozzle 3 vertically connected to the pillar. There are three cables 4 connected between the cantilever nozzle and the upper end of the pillar, and the three cables are equidistantly connected to the cantilever nozzle. The lower end of the pillar is rotatably connected to the base, and the base is provided with a mounting hole 21, and the mounting hole is sequentially provided with a limit ring 22, an abutment spring 23, and an end bearing 24 from top to bottom. The limit cover 25 of the ring, the limit ring outer wall is provided with a circle of limit teeth 26, and the inner wall corresponding to the mounting hole and the limit ring is provided with a circle of limit grooves 27 adapted to the limit teeth, and the limit teeth are connected and positioned In the limit groove, the lower end of the pillar is adapted to connect ...

Embodiment 2

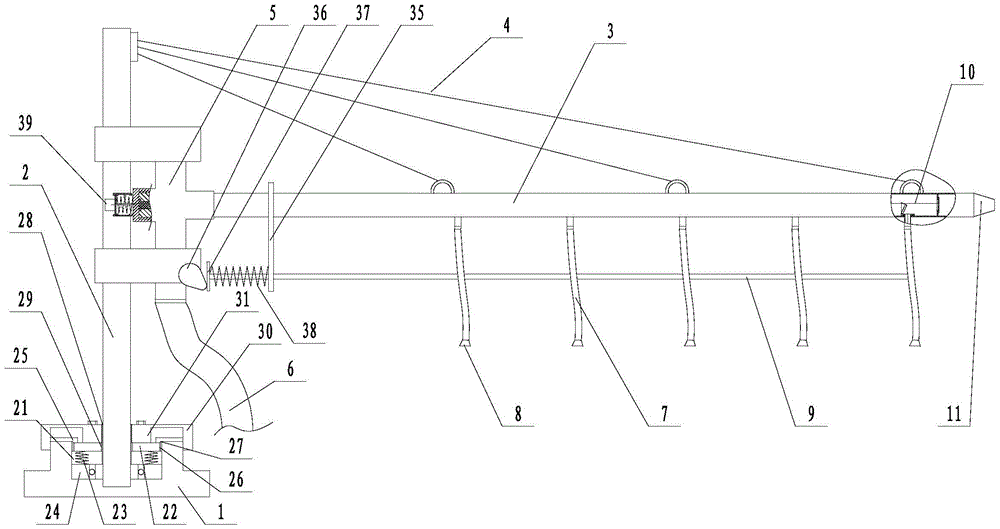

[0023] Embodiment 2: a kind of marine oil spill treatment agent spraying device (see attached figure 2 ), its structure is the same as that of Embodiment 1, the main difference is that the swing mechanism in this embodiment includes a support plate 35 and a cam 36, the support plate is fixedly connected to the cantilever nozzle, the support plate is provided with a socket, and the swing rod is movable to insert Connected in the jack, the rear end of the swing rod is fixedly connected to the push plate 37, and the return spring 38 is sleeved on the swing rod, and the return spring is abutted between the push plate and the support plate, and the cam is fixedly connected to the drive motor output shaft, the cam Set near the push plate. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com