Automatic hardware product soaked-plastic device

A product and automatic technology, which is applied in the field of automatic dipping devices for hardware products, can solve the problems of waste of dipping raw materials, scald operators, low manual operation efficiency, etc., and achieve the effect of high work efficiency and personal safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

[0024] First of all, it should be explained that the automatic plastic dipping device for hardware products provided by the present invention is used in the plastic dipping section of hardware product manufacturing, and is used in conjunction with the hardware product production line (specifically, the clamp that clamps and transmits hardware products) , when the metal products production line moves the semi-finished hardware products to the dipping section through the fixture, the automatic dipping device for hardware products of the present invention can automatically dip the semi-finished hardware products.

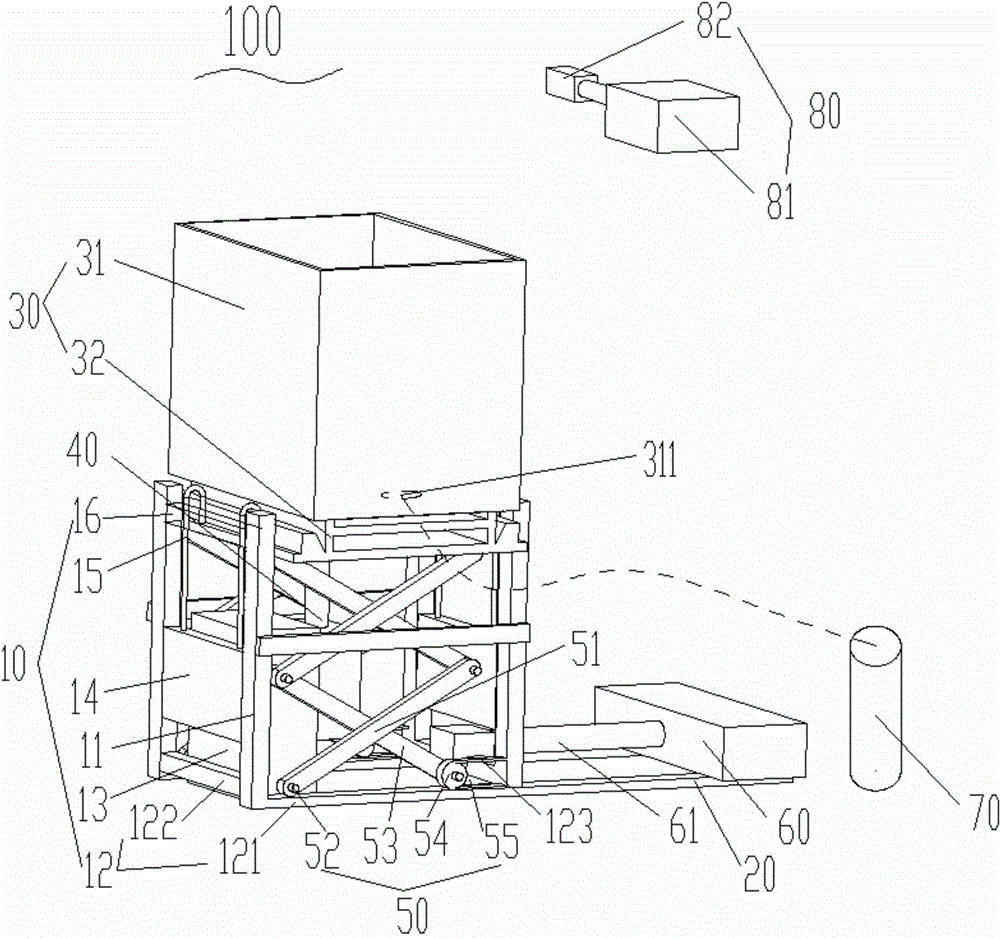

[0025] see figure 1 , the automatic dipping device for hardware products provided by the preferred embodiment of the present invention includes a fixed frame 10, a base 20, a raw material accommodation mechanism 30, a vertical drive cylinder 40, two sets of hinges 50, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap