Direct-driven elevator three-dimensional steering mechanism

A steering mechanism and three-dimensional technology, applied in the field of direct-drive elevator three-dimensional steering mechanism, can solve the problems of low practicality, high cost, and potential safety hazards, and achieve the effect of occupying less building area, simple structure, and quick change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

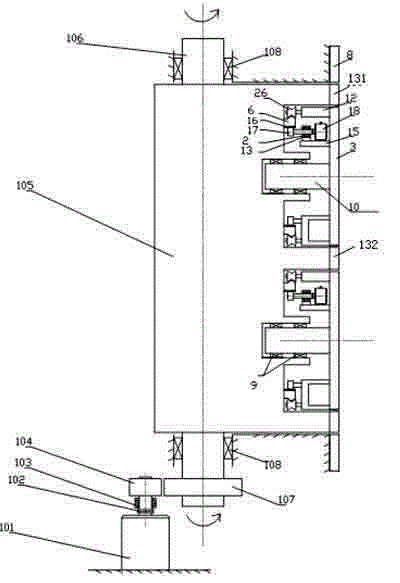

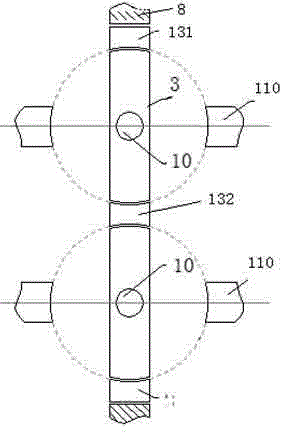

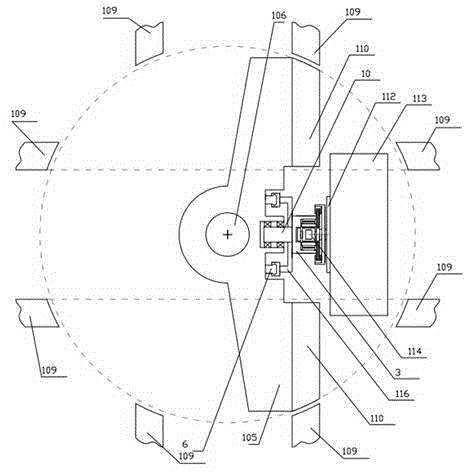

[0021] Such as Figure 1-Figure 5 , the three-dimensional steering mechanism of a direct-drive elevator, including a stator rail, and the stator rail is vertically fixed on a rotating bracket 105 that is a rotating shaft along the vertical direction, and the rotating bracket 105 is provided with a stator steering mechanism corresponding to the floor position of the horizontal stator rail, so that the rotating stator Docking with horizontal stator rails.

[0022] The vertical stator track and the rotating stator constitute a set of rotating mechanisms, and the rotating mechanisms are two sets of back-to-back symmetrical arrangements. The upper and lower sides of the rotating bracket are respectively equipped with steering shafts 106, and the steering shafts 106 pass through the bearings and bearing seats 108 at the upper and lower ends of the shaft. The rotating bracket 105 is rotatably supported in the shaft, and the rotating bracket 105 is driven to rotate by power.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com