Novel peristaltic pump head

A peristaltic pump and pump head technology, applied in the field of pump components, can solve problems such as increased cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

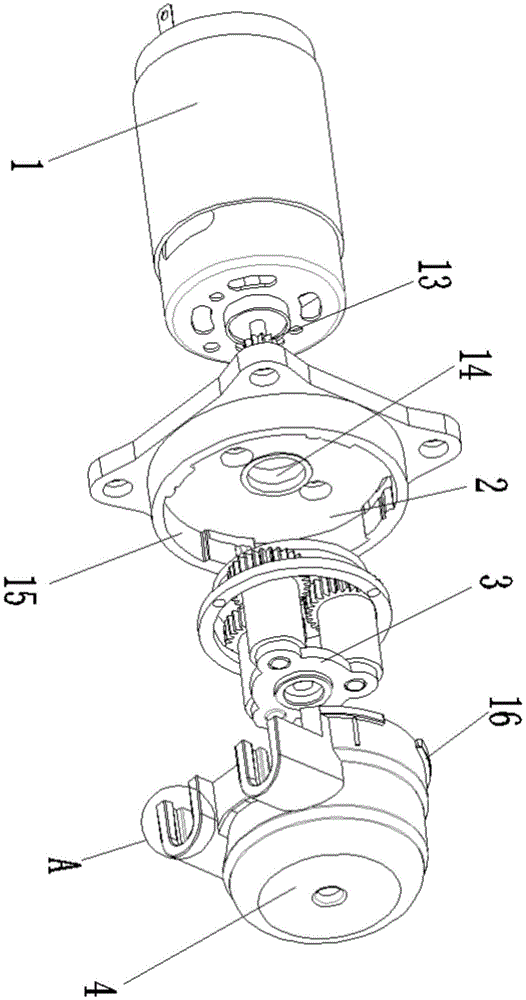

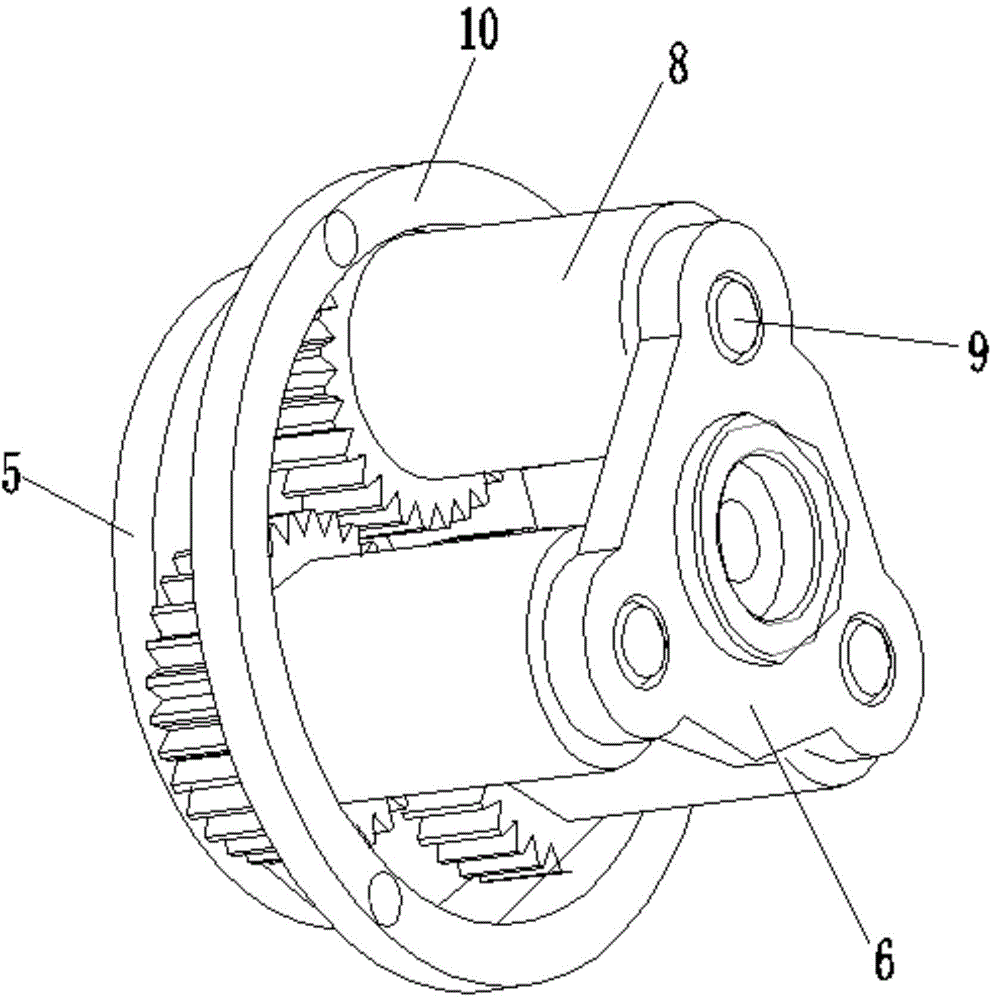

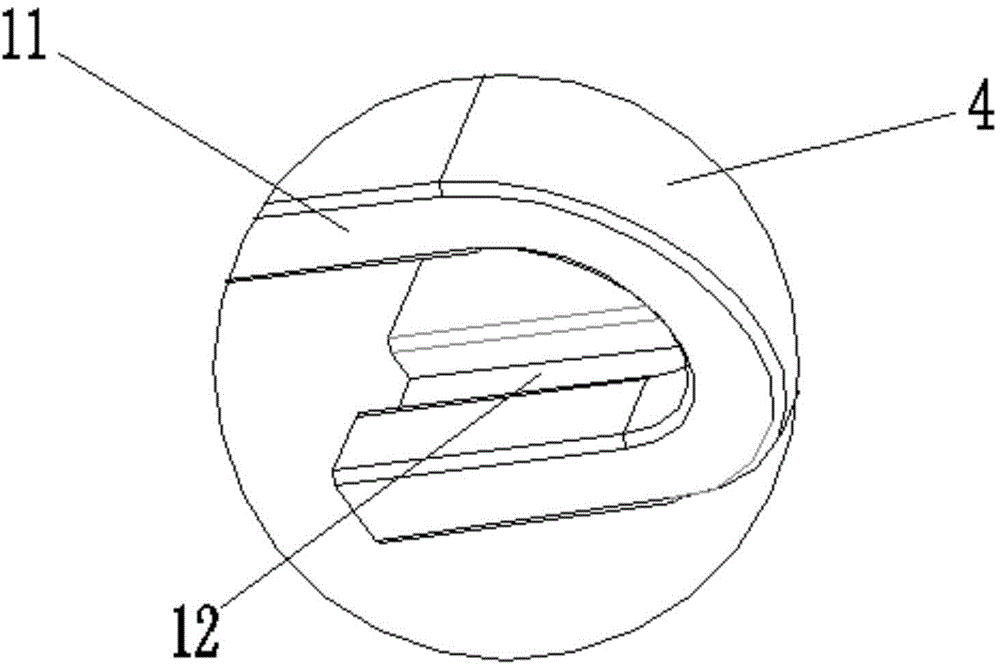

[0014] Such as figure 1 A new type of peristaltic pump head shown includes a micro motor 1, a pump head base 2, a roller assembly 3 and a pump head upper cover 4, the upper surface of the pump head base 2 is provided with grooves, and the The roller assembly 3 is located in the groove of the pump head base 2, the pump head upper cover 4 is connected above the pump head base 2, and the roller assembly 3 is located on the pump head base 2 and the pump head upper cover 4, a through hole 14 is opened at the center of the groove, and the shaft end of the micro motor 1 passes through the through hole 14 to engage with the roller assembly 3, and the shaft end of the micro motor 1 A first gear 13 is provided through which the micro motor 1 is connected with the roller assembly 3 , and two "U"-shaped inlet and outlet nozzles 11 are opened on one side of the pump head cover 4 . The side wall of the groove is provided with a card slot 15, and the outside of the pump head upper cover 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com