Portable in-situ density sensor calibration instrument

A density sensor and calibrator technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of inconvenient use, vacancy, and complexity of density sensors, and achieve easy equipment storage and portability, convenient calibration and use, and stability. good pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

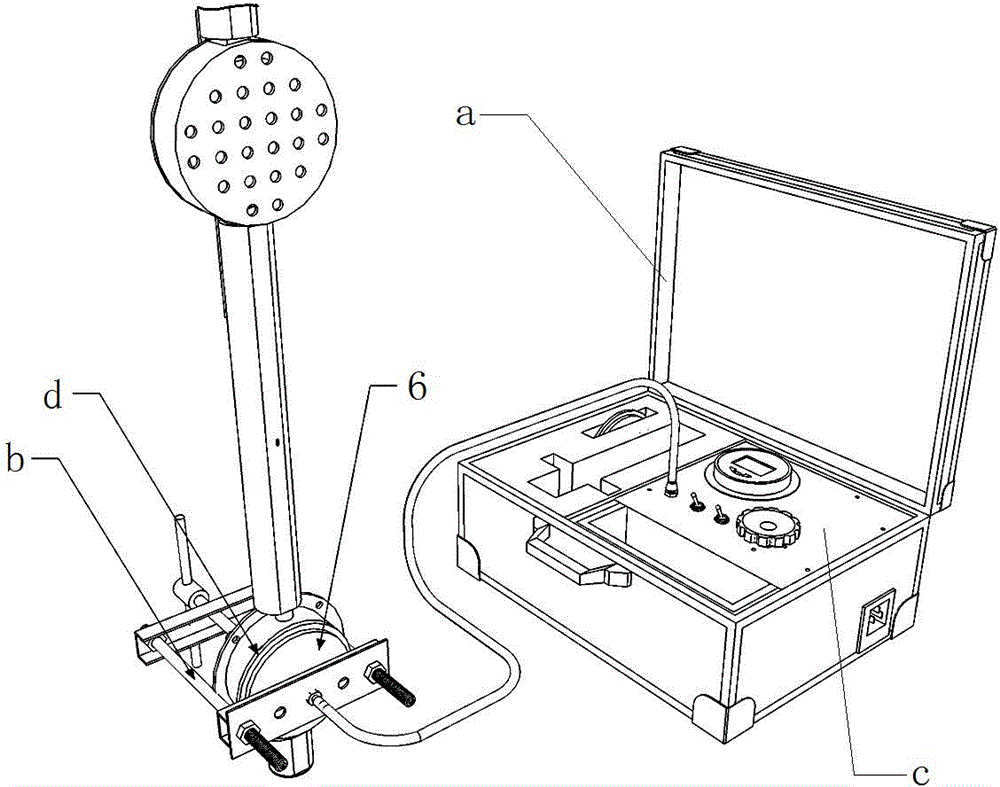

[0019] see figure 1 , a portable on-site density sensor calibrator, including a box body and a calibrator plate fixture b arranged in the box body a and a calibrator body c; two parts are composed of an instrument box, and the calibration plate is on the left Fixture, the right side is the body part of the calibrator.

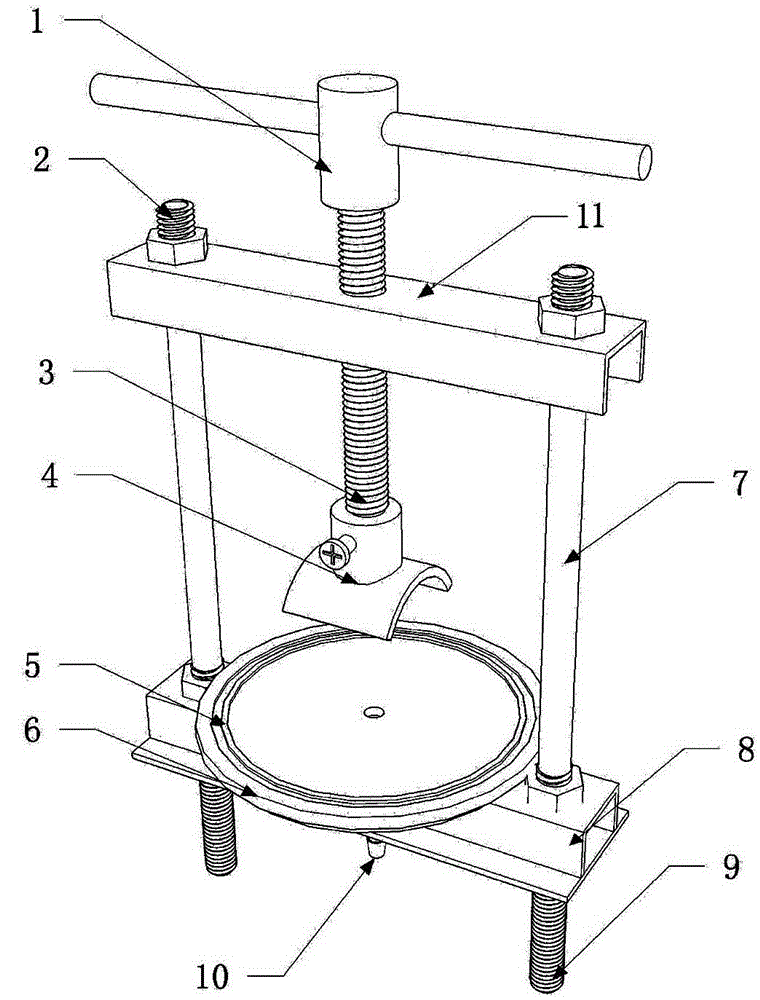

[0020] see figure 2 , the check plate fixture is mainly composed of the check plate bracket upper beam 11, the check plate support lower beam 8, the check plate support pole 7, the check plate 6, the screw 3, the handle 1 and the steel pipe clamp 4, The specific connection is as follows: the upper beam 11 of the check plate support, the lower beam 8 of the check plate support are horizontally spaced up and down and are supported by the check plate support poles 7 on both sides to form a support. The two ends of the check plate support pole 7 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com