LED module light bar production system

A technology of LED modules and production systems, applied in the direction of electrical components, electrical components, etc., can solve the problems of non-uniform size, offset of tiling position, non-uniform return, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

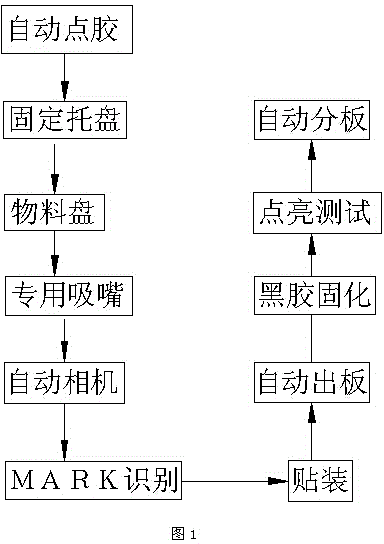

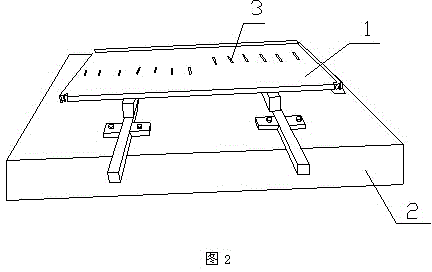

[0015] Such as Figure 1-2 As shown, a LED module light strip production system, which includes an automatic glue dispenser, a fixed tray 1, a material tray, a special suction nozzle, an automatic camera, MARK identification, an automatic placement machine 2, an automatic board ejector, and black glue Curing, lighting test, automatic board splitter, the slot on the material tray is a horn hole shape, the fixed tray 1 is installed on the automatic placement machine 2, the fixed tray 1 is equipped with a positioning device 3, and the special suction nozzle is equipped with Seal rubber ring.

[0016] The material tray is made of RF-4 material.

[0017] The error between material trays is ±0.02mm.

[0018] Install the lens into the material tray according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com