buffer

A technology of buffer and dust cover, applied in shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve problems such as deterioration of dust seals and oil seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0021] The same reference numerals are used in several drawings to designate the same components.

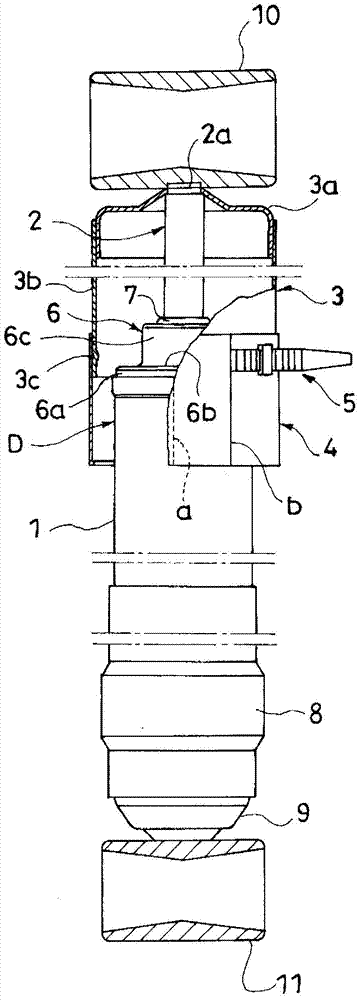

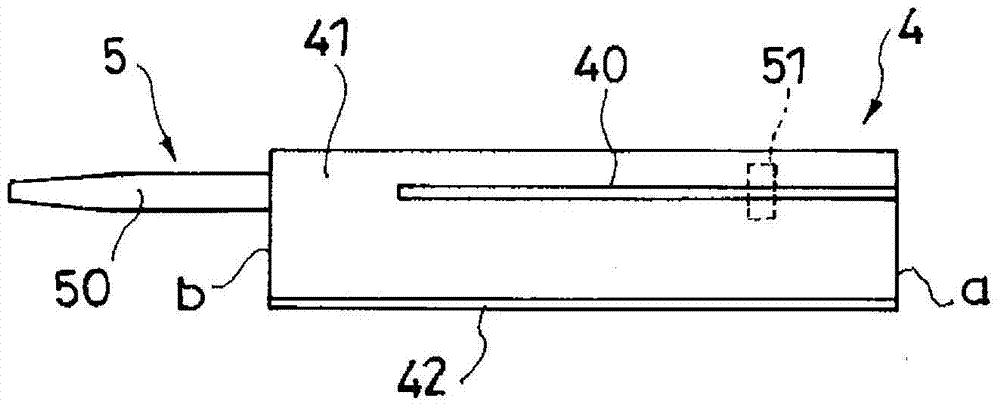

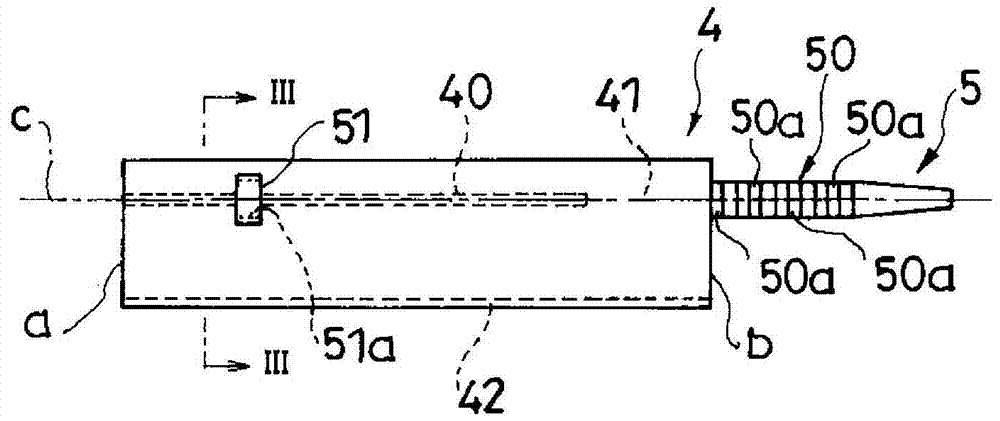

[0022] Such as figure 1 As shown, the buffer includes: a buffer body D, which has a cylindrical shell 1 and a piston rod 2 that freely enters and exits the shell 1, and is used to generate a damping force that inhibits the relative movement of the piston rod 2 relative to the shell 1 in the axial direction. The dust cover 3, which is cylindrical, is connected with the piston rod 2, and allows the casing 1 to enter the inside of the dust cover 3; the extension cover 4, which is formed into a belt, is wound around the outer periphery of the dust cover 3, And extending from the dust cover 3 to the case side, the inner side of the extension cover 4 is penetrated by the case 1 ;

[0023] The damper body D includes, for example, an inner tube (not shown) accommodated in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com