Correcting device for cylindrical refractory blank extruder

A technology for refractory blanks and extruders, applied in the field of correction devices for cylindrical refractory blank extruders, can solve problems such as bending and deformation of refractory blanks, and achieve the effects of increased accuracy, good versatility, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

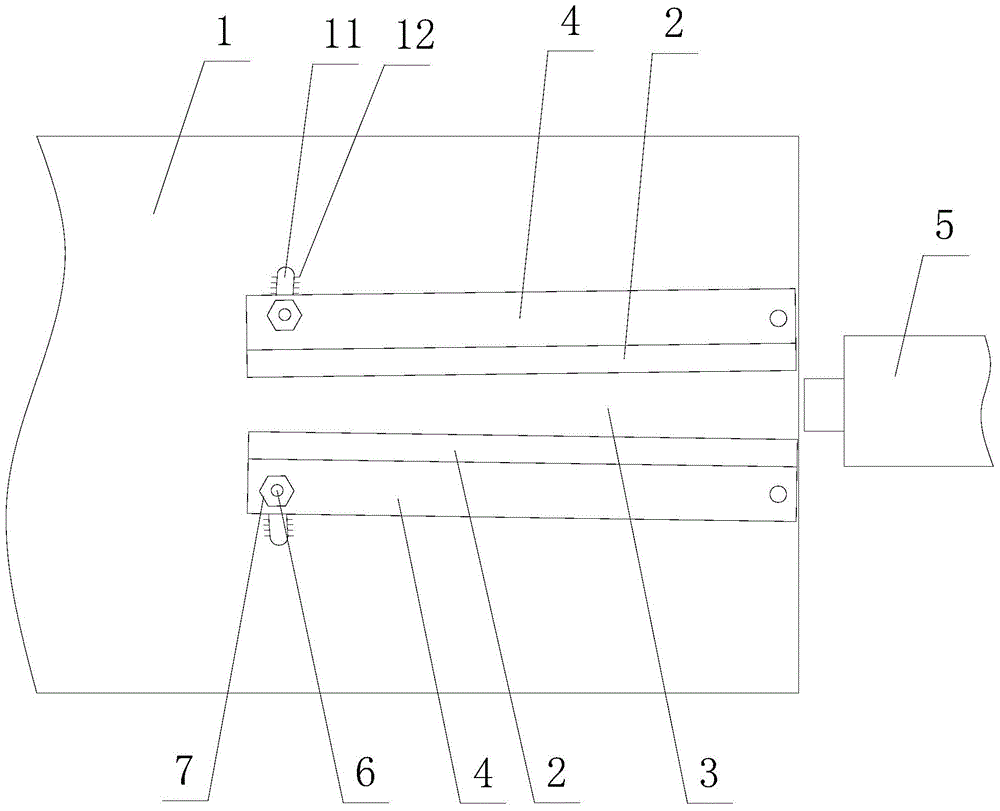

[0011] refer to figure 1 , a straightening device for a cylindrical refractory billet extruder, comprising a base plate 1 and two baffle plates 2, the two baffle plates 2 and the base plate 1 form a U-shaped groove 3, and each baffle plate 2 is fixed with a base plate 1 the supporting plate 4 that fits, the two supporting plates 4 are all located on the outside of the U-shaped groove 3, and the extruder 5 is arranged at the inlet end of the U-shaped groove 3; It is transferred on the base plate 1, and the base plate 1 is provided with two arc-shaped chute 11, and each arc-shaped chute 11 takes the transfer point between the support plate 4 and the base plate 1 as the center of the circle; the exit end of each support plate 4 Each is provided with a bolt 6, the heads of the two bolts 6 are respectively arranged in two arc-shaped chute 11, the screw part of the bolt 6 passes through the support plate 4, and each bolt 6 is connected with a nut 7; The U-shaped groove 3 gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com