Manufacturing method of pneumatic tire

A manufacturing method and technology for pneumatic tires, which can be applied to tires, other household appliances, household appliances, etc., can solve the problems of difficult to extrude conductive layers, difficult to control the volume of each layer, etc., and achieve the effect of ensuring electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will be described below with reference to the drawings.

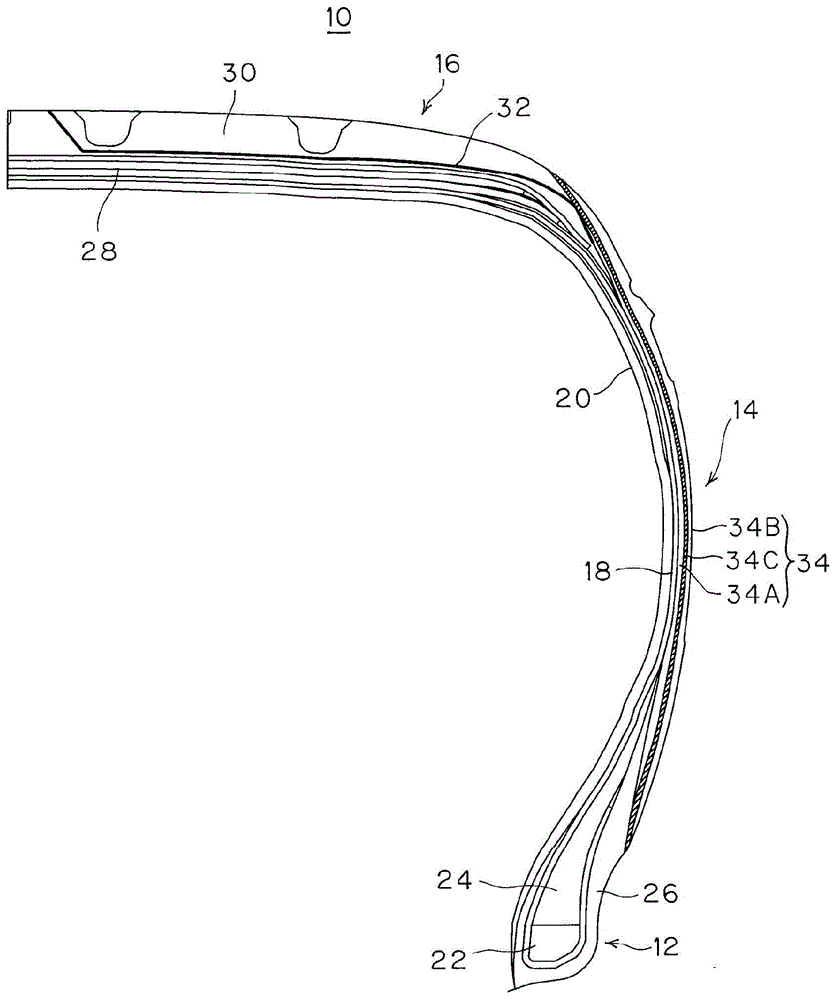

[0057] like figure 1 As shown, the pneumatic tire 10 of the present embodiment includes: a pair of bead portions 12; a pair of sidewall portions 14 extending from the bead portions 12 outward in the tire radial direction; and a tread portion 16 connecting the two tires. The radially outer ends of the side portions 14 are disposed between the two sidewall portions 14 in relation to each other.

[0058]An annular ply 18 extending across a pair of bead portions 12 is buried inside the tire. The carcass ply 18 is composed of at least one carcass ply, and both ends of the carcass ply 18 are locked to the bead portions 12 . The carcass ply is formed by covering cords arranged in a direction substantially perpendicular to the tire circumferential direction with a topping rubber composed of non-conductive rubber. Inside the carcass 18, an inner liner 20 for maintaining air pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com