A turning discharging device

A technology of raw materials and storage bins, applied in the field of unpacking and unloading devices, can solve problems such as low work efficiency and inability to adapt to industrial production, and achieve the effects of saving production costs, reducing labor input, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

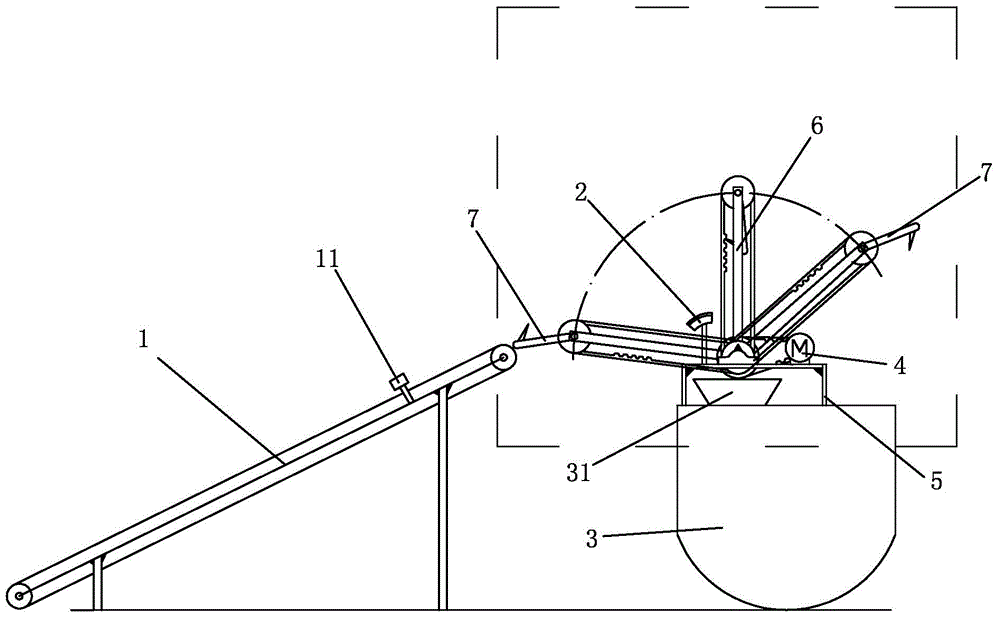

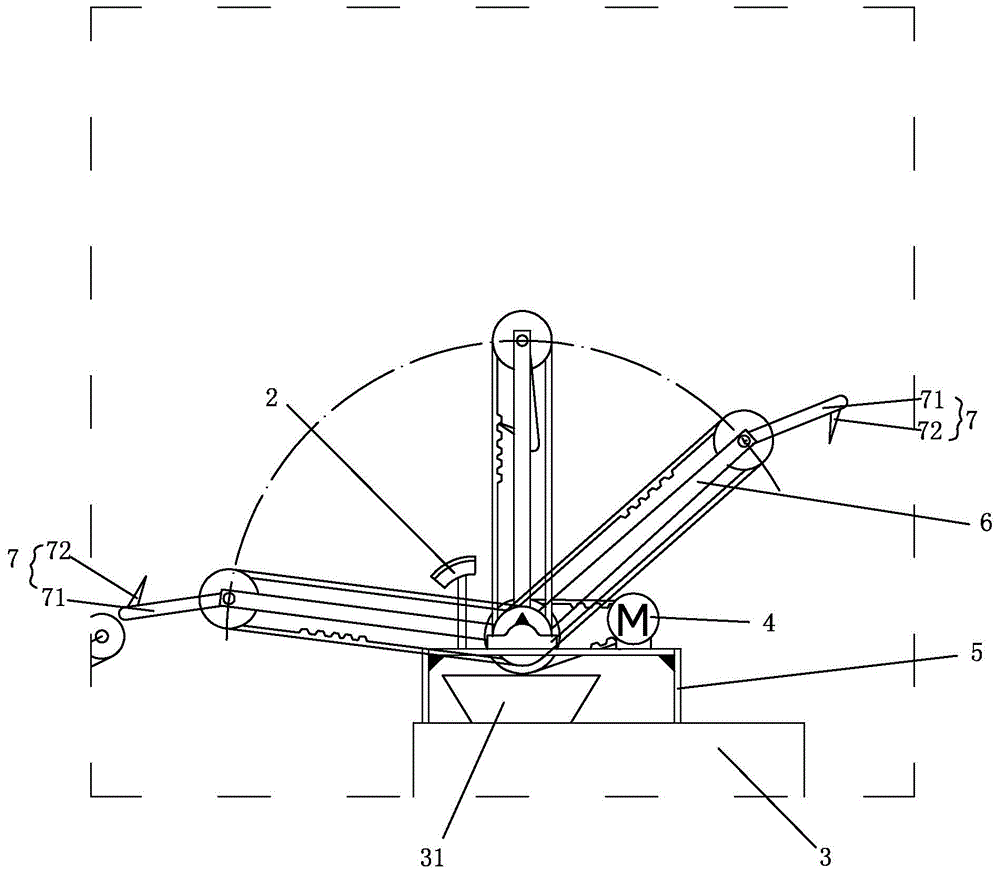

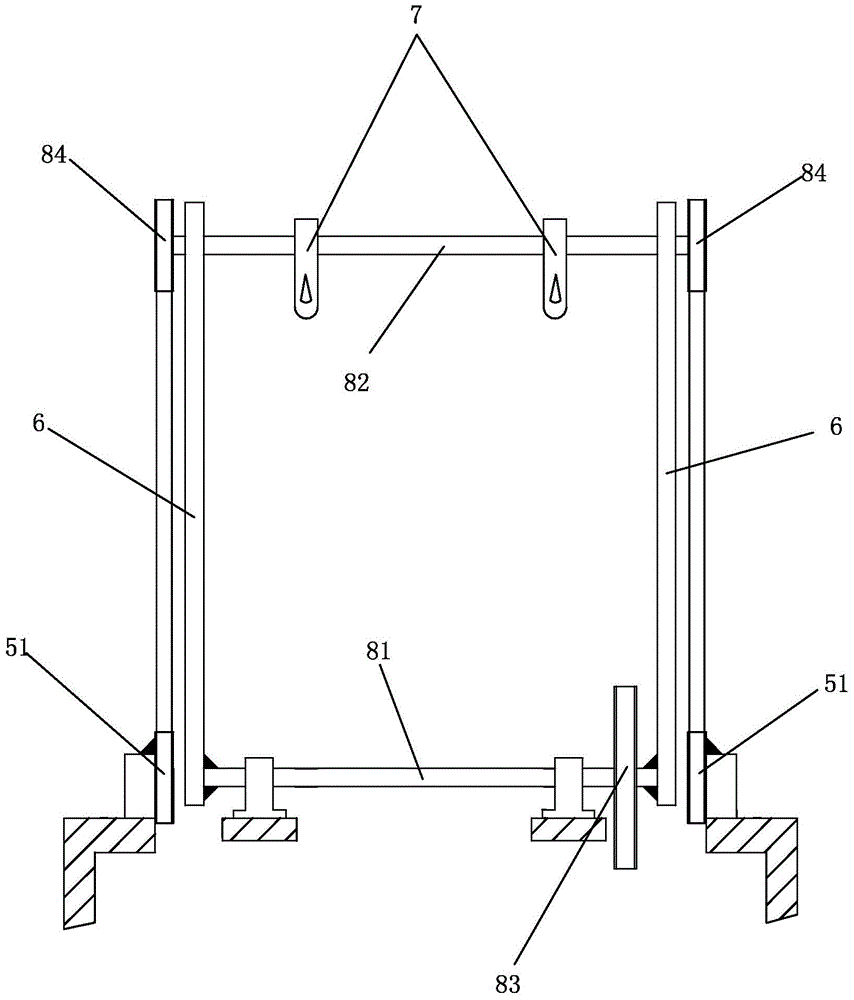

[0024] See Figure 1 to Figure 3 As shown, a turning and unloading device of the present invention includes a conveying mechanism 1, a cutting mechanism 2, a storage bin 3, a driving mechanism 4, a fixed bracket 5, a turning truss 6, a first pivot shaft 81 and a hook mechanism 7 The bagged solid raw material is transported from one end of the conveying mechanism 1 to the other end, and the conveying mechanism 1 drives the bagged solid raw material to pass through the cutting mechanism 2, so that the solid raw material enters the storage bin 3 after the packaging bag is broken; also includes, One end of the overturning truss 6 is rotatably mounted on the fixed bracket 5 through the first pivot shaft 81, and the other end of the overturning truss 6 is provided with a hook mechanism 7, so that the bagged solid raw materials are separated from the other end of the conveying mechanism 1 and hung on the Turn over the truss 6, and pass through the cutting mechanism 2 along with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com