Vacuum cup vacuumizing device and working principle of vacuumizing device

A technology of vacuuming device and working principle, which is applied in packaging, drinking vessels, etc., can solve the problems of low thermal insulation performance and high production cost, achieve high sealing performance and solve the effect of long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

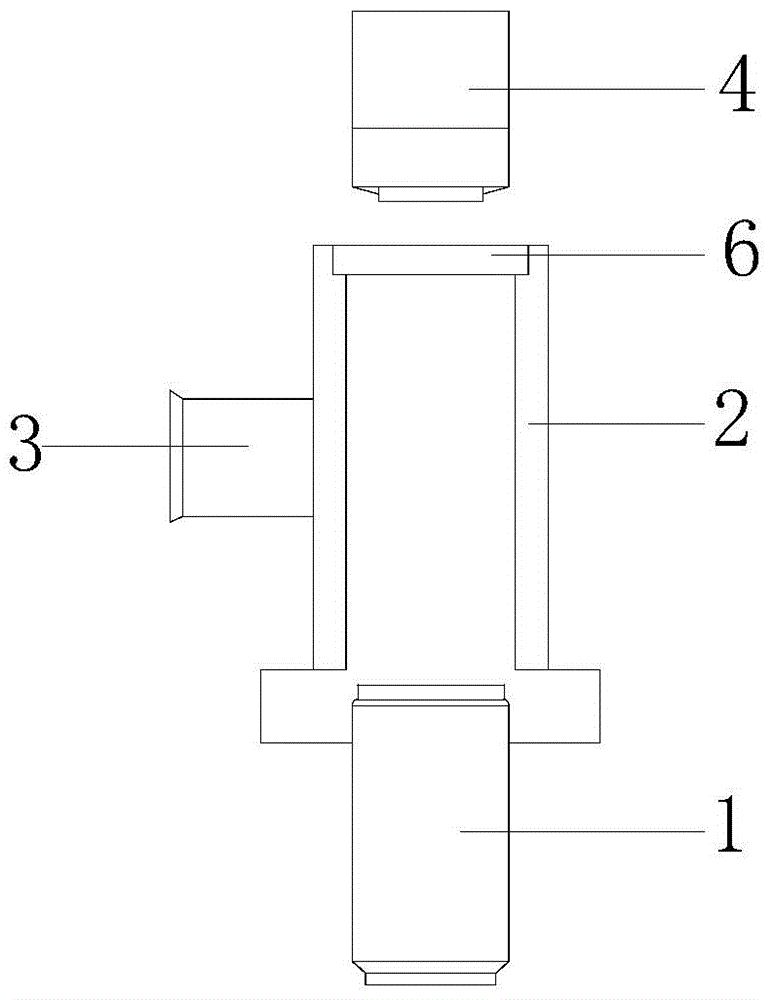

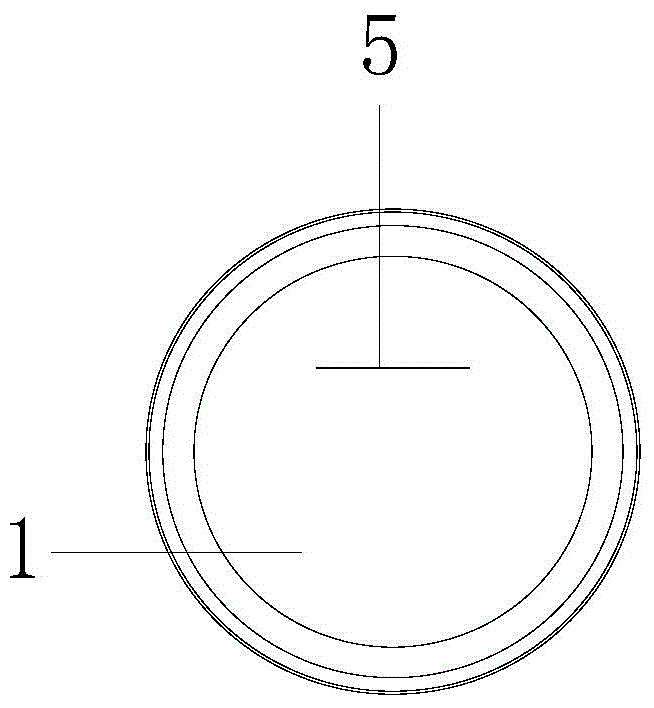

[0027] Please combine figure 1 and figure 2 Shown, a kind of thermos cup vacuumizing device of the present invention, wherein, comprises:

[0028] A thermos cup 1, the thermos cup 1 is a metal thermos cup and a gap 5 is provided at the bottom of the thermos cup;

[0029] The sealing fixture 2 is used to clamp the thermos cup 1. The bottom of the sealing fixture 2 has an installation opening, and the thermos cup 1 is connected to the sealing fixture 2 through the installation opening;

[0030] The vacuum interface 3 is arranged on the sealing fixture 2, and is used to evacuate the inside of the thermos cup 1 fixed on the sealing fixture 2, and the vacuum interface 3 is connected to the vacuum machine;

[0031] The laser welding machine is used for welding the gap 5 at the bottom of the thermos cup 1 to achieve the effect of sealing.

[0032] On the basis of the above, the present invention also has the following implementation modes, please continue to refer to figure 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com