Composite structural idler and preparation method of corresponding synergistically modified friction material

A composite material and friction material technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of insufficient thermal and mechanical properties to cope with high-speed friction, increased friction coefficient of polyamide, and poor dimensional stability. Achieve low friction coefficient, excellent wear resistance, and improve friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

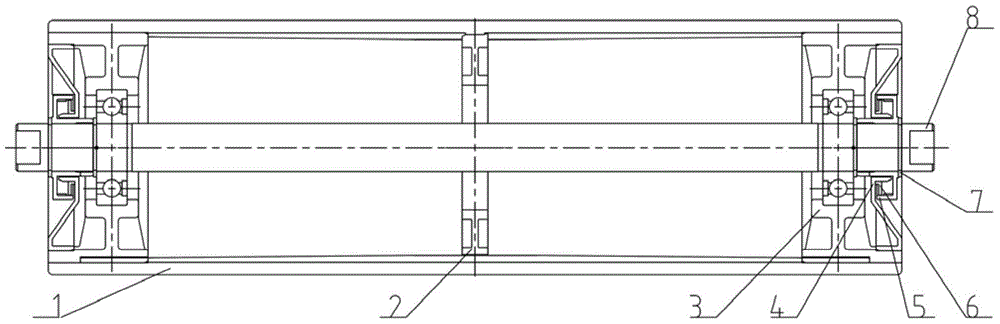

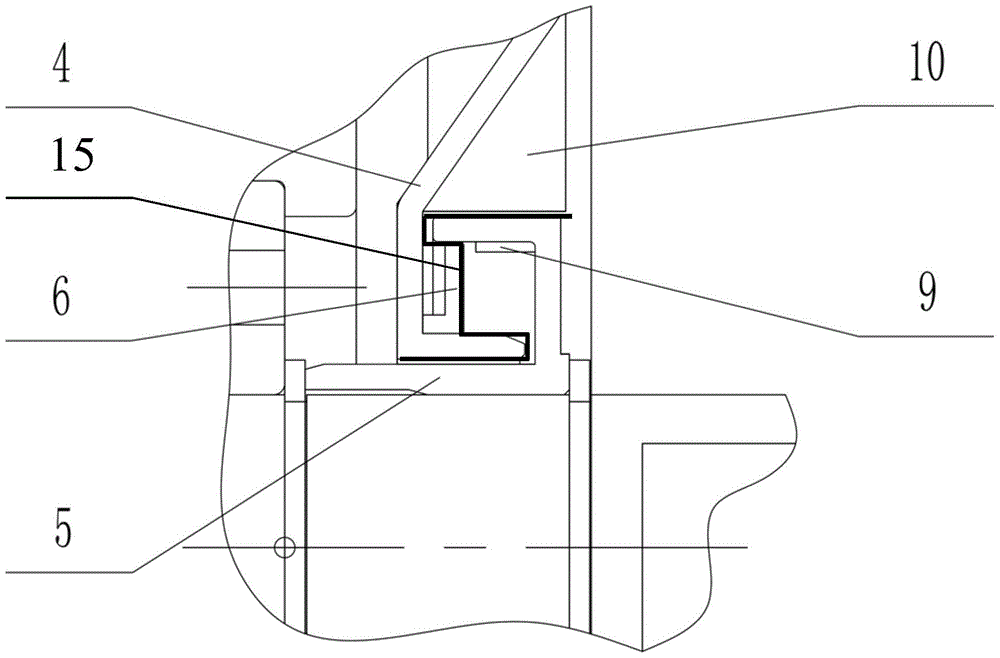

[0040] like Figures 1 to 7 As shown, the composite material structure idler includes a cylinder assembly, two bearing housings 3 containing bearings arranged on both sides of the cylinder assembly, and a sealing assembly connected to each bearing housing 3;

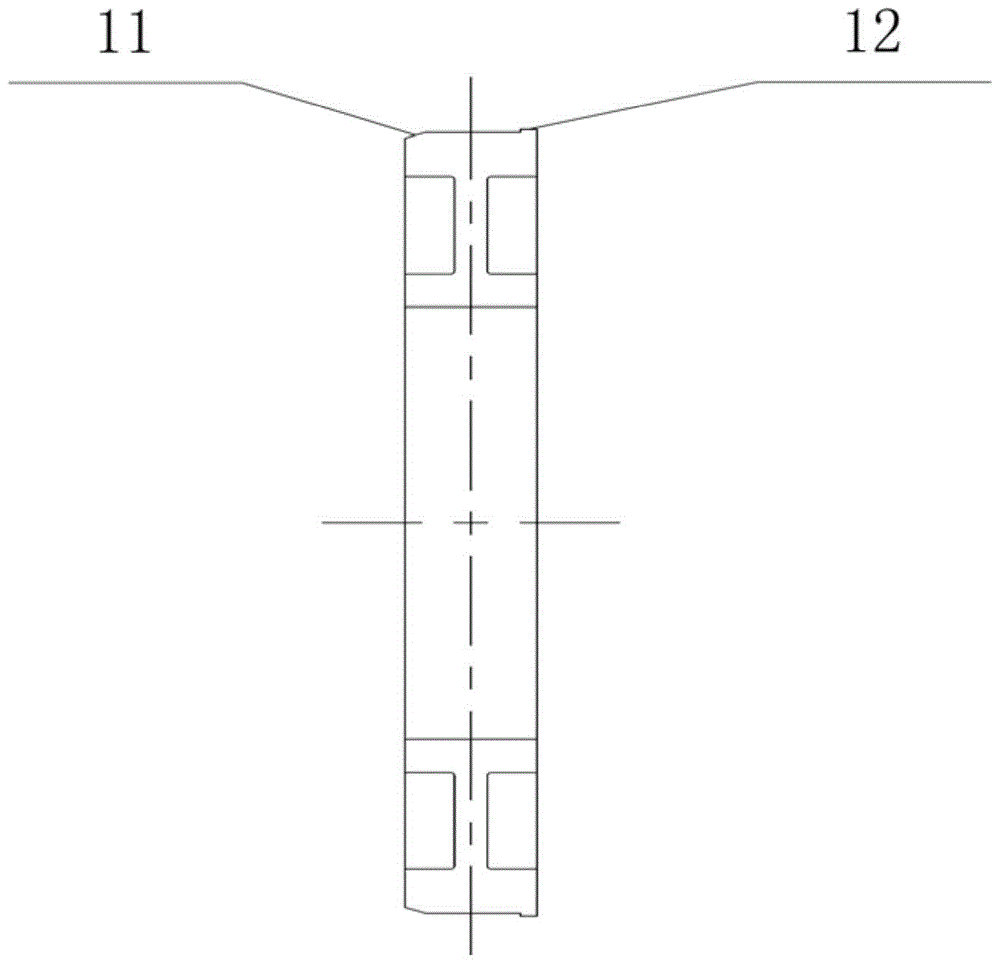

[0041] The barrel assembly includes a barrel 1 and a shaft 8 penetrating through the barrel 1 and the sealing assembly along the central axis; a retaining spring 7 is arranged outside the shaft.

[0042] The sealing assembly includes a sealing base 4 tightly matched with the bearing housing 3, and a sealing cover 5 closely matched with the sealing base 4. A sealed space is formed between the outer surfaces of the sealed space, and a sealed spacer ring 6 is installed in the sealed space, and the sealed space and the sealed spacer ring 6 form a labyrinth seal structure along the sealing route 15 . The sealing base 4 , the sealing spacer ring 6 and the sealing outer cover 5 can axially move in series due to the existence o...

Embodiment 2

[0049]1) Dissolve the coupling agent in a water-ethanol solution with a mass ratio of 1:9, add graphene or PTFE micropowder to be modified, and use ultrasonic dispersion for 1.5 to 3 hours to dry to constant weight. as a surface modifier. 2) According to the mass fraction of polyamide 75%, modified graphene: 5%, modified PTFE: 9.5%, glass fiber: 10, antioxidant 1010: 0.5% batching. 3) Mix at high speed for 0.5 hours, and mix evenly at a speed of 300-600 rpm; 4) The temperature of the twin-screw extruder is controlled at 190-250°C for mixing and extrusion, and the water-cooled pelletizer is cut into specifications of Φ2.5 ×4 pellets; 5) Dry at 100° C. for 3 hours.

[0050] The materials of this formula are analyzed and evaluated, and the following basic properties are obtained. Axial tensile strength: 71MPa, notched impact strength: 27.7KJ / m 2 , friction coefficient: 0.11, wear rate: 5.5×10 -6 mm 3 / Nm.

Embodiment 3

[0052] 1) Dissolve the coupling agent in a water-ethanol solution with a mass ratio of 1:9, add the graphene or PTFE micropowder to be modified, and use ultrasonic dispersion for 1.5 to 3 hours to dry to constant weight. 2) According to the mass fraction of polyamide 79%, modified graphene: 3%, modified PTFE: 7.7%, glass fiber: 10, antioxidant 1010: 0.3% batching. 3) Mix at high speed for 0.5 hours, and mix evenly at a speed of 300-600 rpm; 4) The temperature of the twin-screw extruder is controlled at 190-250°C for mixing and extrusion, and the water-cooled pelletizer is cut into specifications of Φ2.5 ×4 pellets; 5) Dry at 100° C. for 3 hours.

[0053] The materials of this formula are analyzed and evaluated, and the following basic properties are obtained. Axial tensile strength: 67MPa, notched impact strength: 23KJ / m 2 , friction coefficient: 0.17, wear rate: 6.3×10 -6 mm 3 / Nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com