Semi-prefabricated underground continuous wall and construction method thereof

An underground continuous wall and prefabricated wall technology, applied in excavation, sheet pile wall, infrastructure engineering and other directions, can solve problems such as groundwater leakage, meet the requirements of reducing hoisting equipment, easy to ensure construction quality, and avoid groundwater leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings.

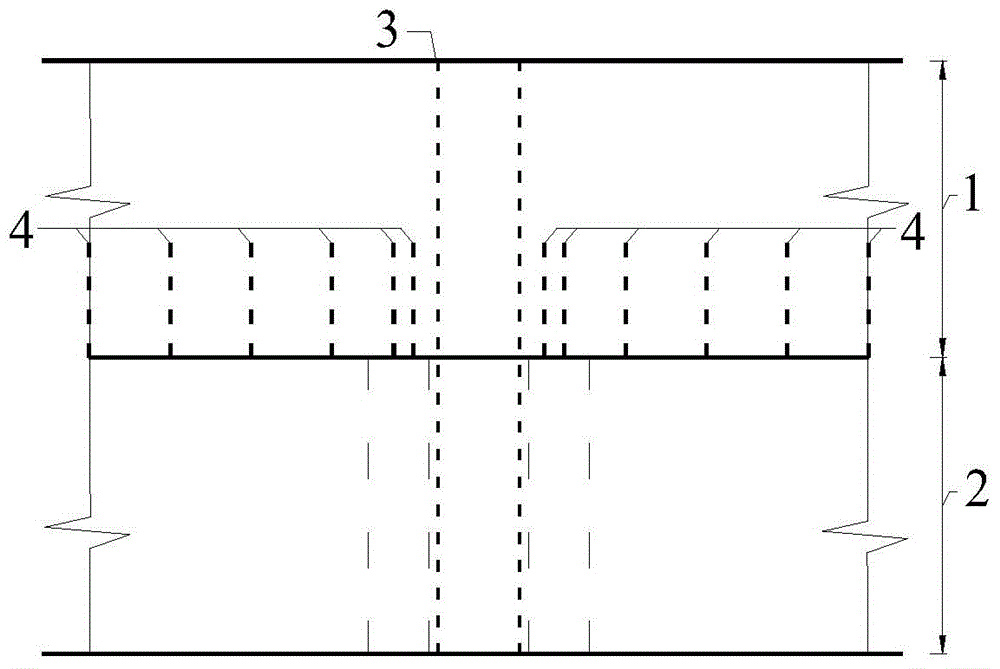

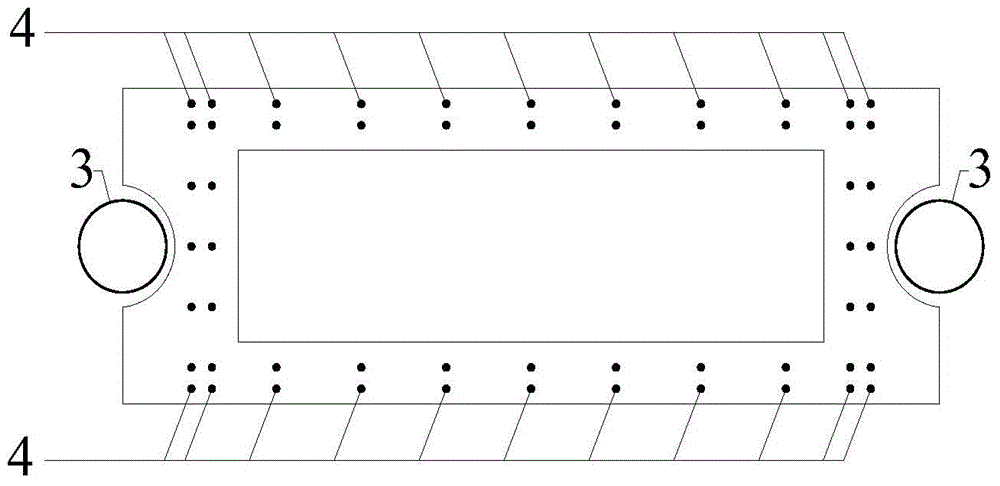

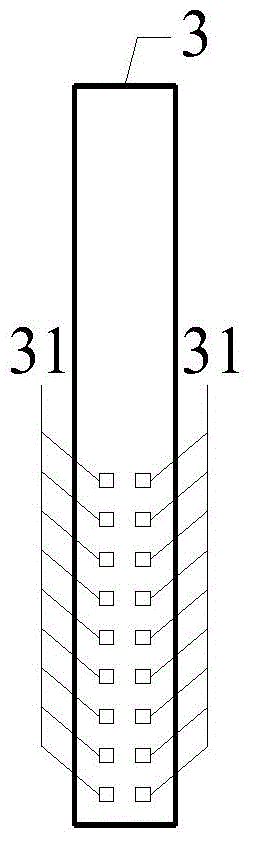

[0028] Such as figure 1 As shown, a semi-prefabricated underground continuous wall includes a lower prefabricated wall 2 and an upper post-cast wall 1 . The lower prefabricated wall 2 includes several prefabricated wall sections, and the top of the prefabricated wall section is provided with connecting ribs 4, and the adjacent prefabricated wall sections are connected by steel pipe joints 3, such as figure 2 shown. The length of the steel pipe joint 3 is equal to the overall height of the semi-prefabricated underground diaphragm wall. A number of through holes 31 are preset on the pipe wall connecting the steel pipe joint 3 and the prefabricated wall section. The overall length of the steel pipe joint 3 with the through holes 31 is equal to the The height of the section; in order to ensure that the poured concrete flows smoothly into the steel pipe hole, the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com