Flywheel for electric bicycle mechanical variable speed motor

An electric bicycle, variable speed technology, applied in the field of bicycle parts, can solve the problems of the deceleration mechanism stuck, unable to work, power source stuck, etc., to achieve the effect of compact structure, small size, and insufficient internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

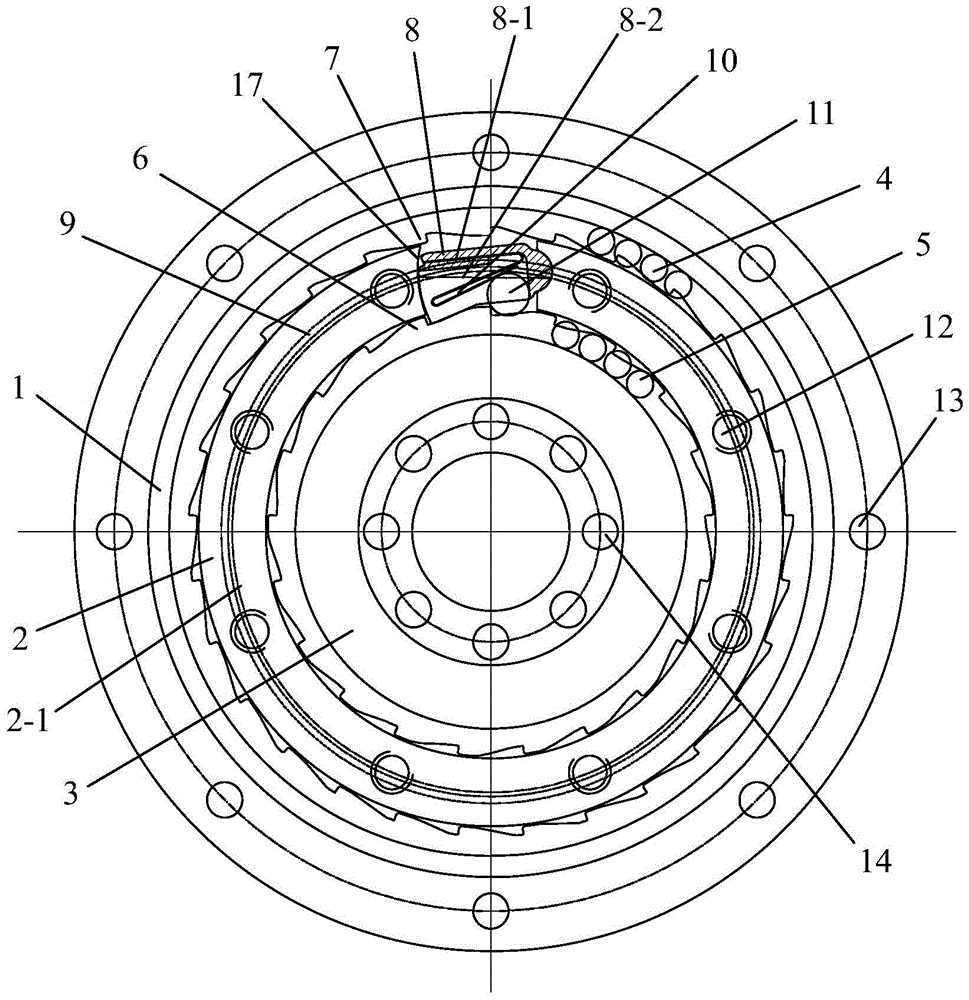

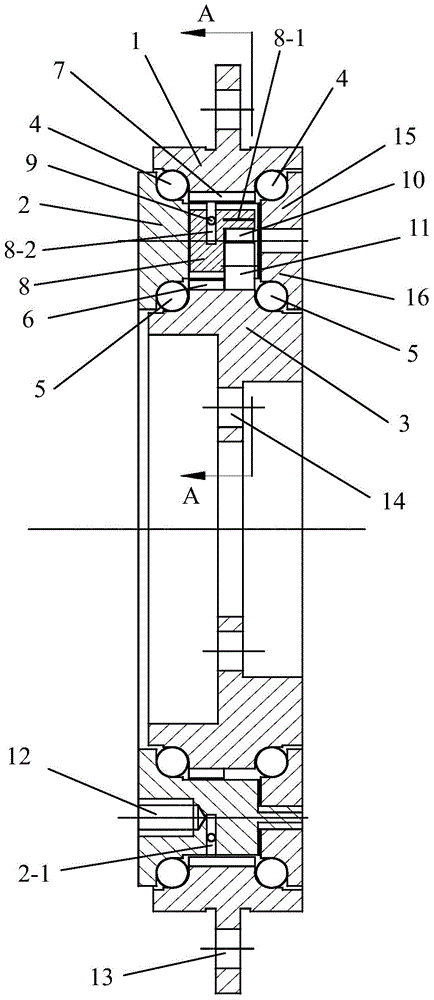

Embodiment 1

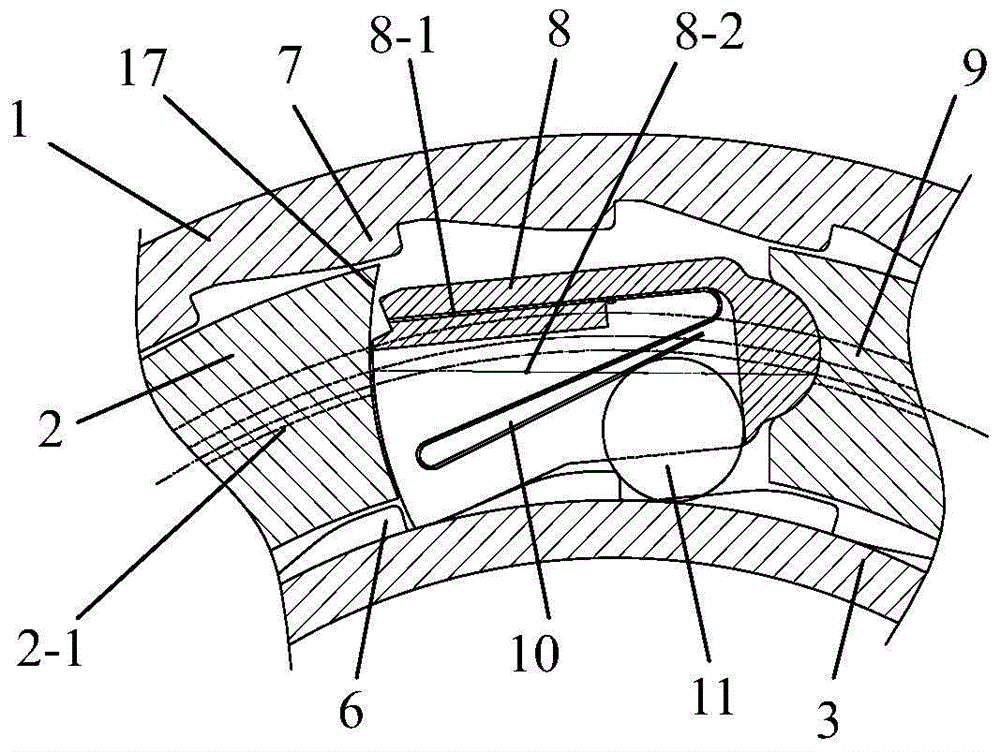

[0025] The preferred solution of this embodiment is that the side surface of the jack piece of the two-way jack control mechanism is provided with a stepped concave platform containing the return spring and the needle roller, the shape of the back spring is an S-shaped leaf spring 10, and the front end of the leaf spring is embedded in the jack In the leaf spring fixing slot 8-1 on the bottom surface of the step concave platform, the lower surface of the leaf spring rear end is in contact with the needle roller 11.

[0026] attached Figure 3-1 As shown, when the needle roller is located on the right side below the jack, the deformation of the leaf spring is small, and the upward jacking force is smaller than the tightening force of the circlip steel wire, and the jack goes down under the action of the tightening force of the circlip steel wire to contact the pawl of the inner ring. .

[0027] Figure 3-2 As shown, when the inner ring rotates counterclockwise, the needle rol...

Embodiment 2

[0030]The preferred version of this embodiment is that the two-way jack control mechanism includes a jack, a ball 18 on the upper side of the jack, a ball 19 on the lower side of the jack, and a ball spring 20. The rear end of the jack is radially provided with a circular hole, and the circle Place the ball on the upper side of the jack, the ball spring and the ball on the lower side of the jack in sequence in the hole.

[0031] Pic 4-1 As shown, when the outer ring rotates counterclockwise and the inner ring rotates clockwise, the friction force between the ball, the outer ring and the inner ring makes the jack piece rotate counterclockwise and contacts the pawl of the inner ring.

[0032] Figure 4-2 and Figure 4-3 As shown, when the outer ring rotates clockwise and the inner ring rotates counterclockwise, the friction force between the ball, the outer ring and the inner ring makes the jack rotate clockwise and contacts the pawl of the outer ring.

Embodiment 3

[0034] The preferred solution of this embodiment is that the two-way jack control mechanism includes a gold plate 8 and a spring hook 21, the shape of the spring hook is Z-shaped, and the front end of the spring hook is embedded in the leaf spring fixing groove on the upper surface of the jack plate. The rear end is in contact with the inner ring ratchet tooth surface.

[0035] Figure 5-1 As shown, the jack piece is lifted upwards under the elastic force of the spring hook and contacts the pawl of the outer ring, the outer ring rotates clockwise, when the inner ring rotates counterclockwise, the outer ring drives the middle fixed ring to rotate clockwise, and the spring hook is inside The ring surface is slippery.

[0036] Figure 5-2 and Figure 5-3 As shown, when the outer ring rotates counterclockwise and the inner ring rotates clockwise, the spring hook hooks the pawl of the inner ring, so that the spring hook drives the jack piece to rotate counterclockwise, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com