Multi-layer automatic circulation perlite plate drying kiln

A technology of perlite plate and automatic circulation, which is applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of high labor cost, high drying cost, low drying efficiency, etc., and achieve high degree of automation, Good drying effect and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

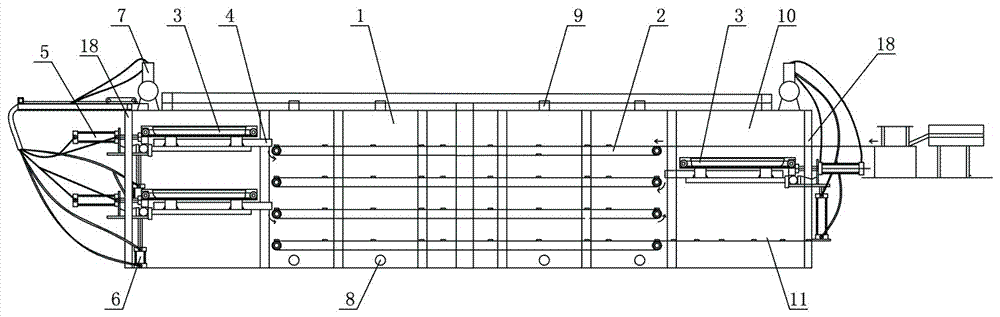

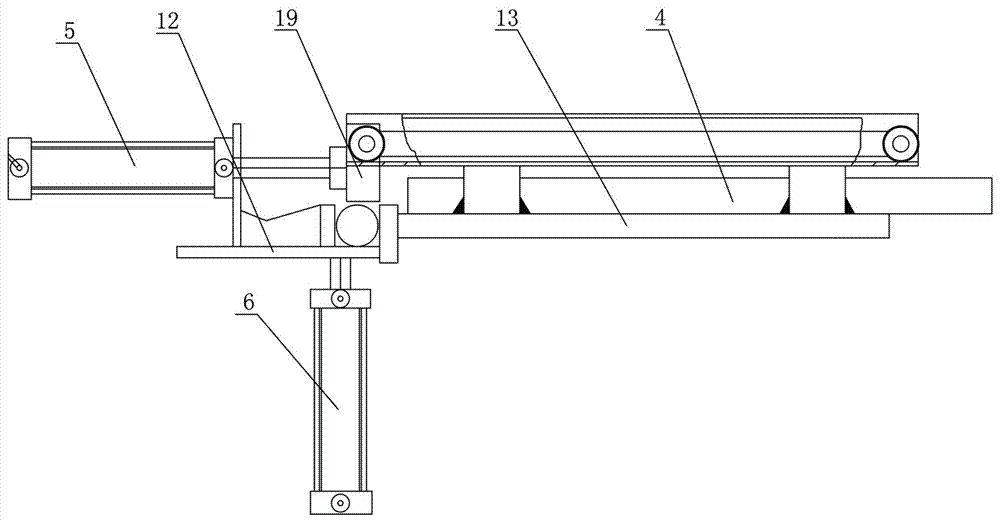

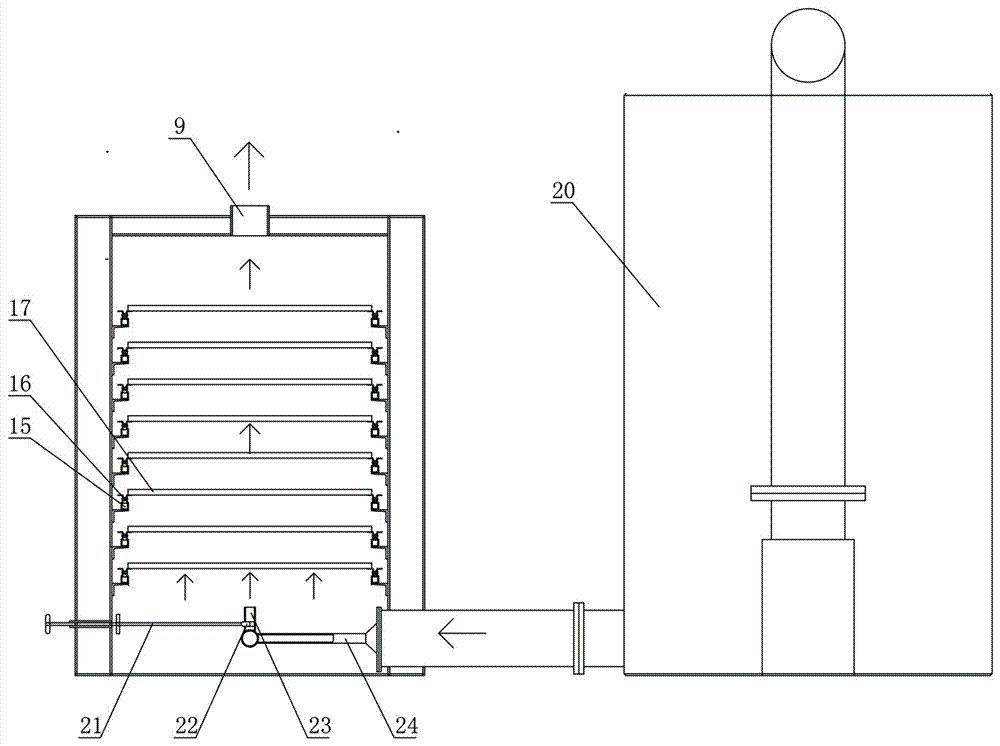

[0034] Such as figure 1As shown, a multi-layer automatic circulation type perlite slab drying kiln includes a drying box 1, a hot air system for heating the drying box 1, and 4 layers of parallel kilns arranged in the drying box 1. Roller conveying chain mechanism 2, described roller conveying chain mechanism 2 comprises the rail 15 that is arranged on the inner side wall of described drying box 1, the chain 16 that is installed in two rails 15, is located between two chains 16 The stainless steel round pipe 17 and the driving shaft and the driven shaft installed at the two ends of the two chains 16, the four driving shafts are respectively driven by four worm gear reducers, the steering of the adjacent two-layer roller conveyor chain mechanism 2 is opposite, and the two adjacent The worm gear reducers of the layer roller conveyor chain mechanism 2 are located at different ends of the drying box 1, and the first layer roller conveyor chain mechanism 2 and the fourth layer roll...

Embodiment 2

[0041] The difference between this embodiment and the above embodiments is that it also includes a photoelectric sensor arranged at the tail end of the conveying plate corresponding to each layer of roller conveyor chain mechanism and a controller connected to each photoelectric sensor. cylinder and the transverse cylinder. Its purpose is to realize automation without human operation. When the plate moves to the end of the conveying plate, the photoelectric sensor detects the position signal and sends it to the controller. Pick up work, high degree of automation, saving labor costs.

Embodiment 3

[0043] The difference between this embodiment and the above embodiments is that the automatic material receiving and feeding frame includes a frame that slides and fits with the drying box 1 in the vertical direction, is fixed on the drying box and drives the frame The vertical cylinder that reciprocates between the adjacent two layers of roller conveyor chain mechanisms, the secondary roller conveyor chain mechanism that is installed on the frame and cooperates with the roller conveyor chain mechanism, and the secondary roller conveyor chain mechanism that drives the secondary roller conveyor chain mechanism The secondary worm gear reducer; the secondary worm gear reducer is linked with the vertical cylinder, when the vertical cylinder drives the frame to make the secondary roller conveyor chain mechanism flush with the roller conveyor chain mechanism, The auxiliary worm reducer and the worm reducer of the corresponding roller conveyor chain mechanism turn in the same directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com