A bearing plate for real-time collection of vertical stress at each point on the end face of coal and rock mass

A real-time acquisition, vertical stress technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of acoustic emission interference, interference with the accuracy of mechanical parameters of rock samples, uneven distribution of end stress, etc., to eliminate friction. Effects, sample size requirements are wide, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

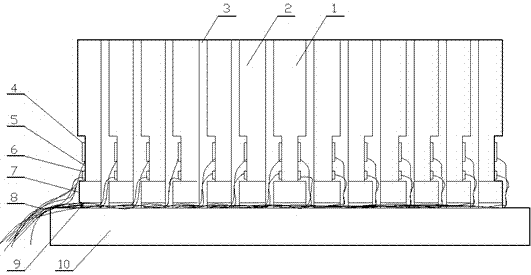

[0012] The present invention will be further described below in conjunction with the accompanying drawings: a pressure bearing plate for real-time collection of vertical stress at various points on the end face of a coal rock mass, mainly including a bearing column 1, a bearing ring 2, a vertical strain gauge 4, a horizontal strain gauge 6, and a wire 8 And the base 10, the bearing column 1 is located in the middle, and a plurality of bearing rings 2 of equal height are sleeved along the radial direction outside the bearing column 1. The upper and lower end surfaces of the bearing rings 2 are all on the same horizontal plane, and the bearing column 1 and the bearing The central axes of the rings 2 coincide, and the number of bearing rings 2 can be increased or decreased correspondingly according to the size of the rock sample to be measured. There is a compensation gap 3 between adjacent bearing rings 2 to adapt to the transverse direction of the end face of the sample during co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com