Method for testing wear resistance of surface coating of profile via falling sand tester

A surface coating and testing machine technology, applied in the direction of testing wear resistance, etc., can solve problems such as troubles, different wear resistance measurement results, and accurate detection of profile surface quality, to achieve accurate measurement and strong concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

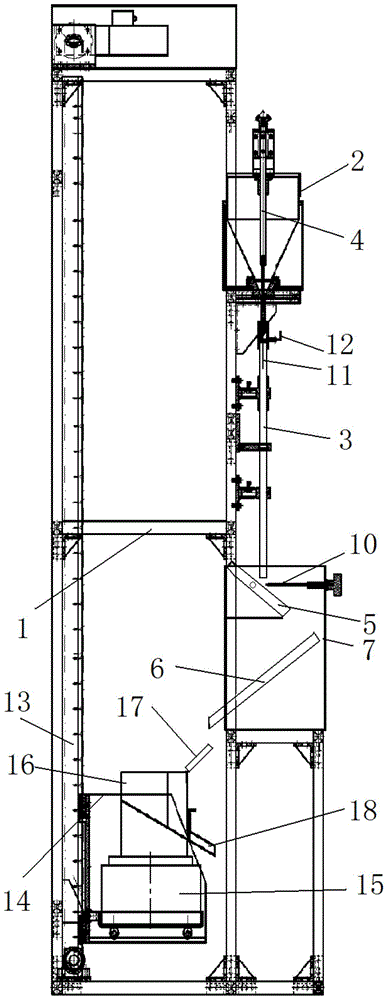

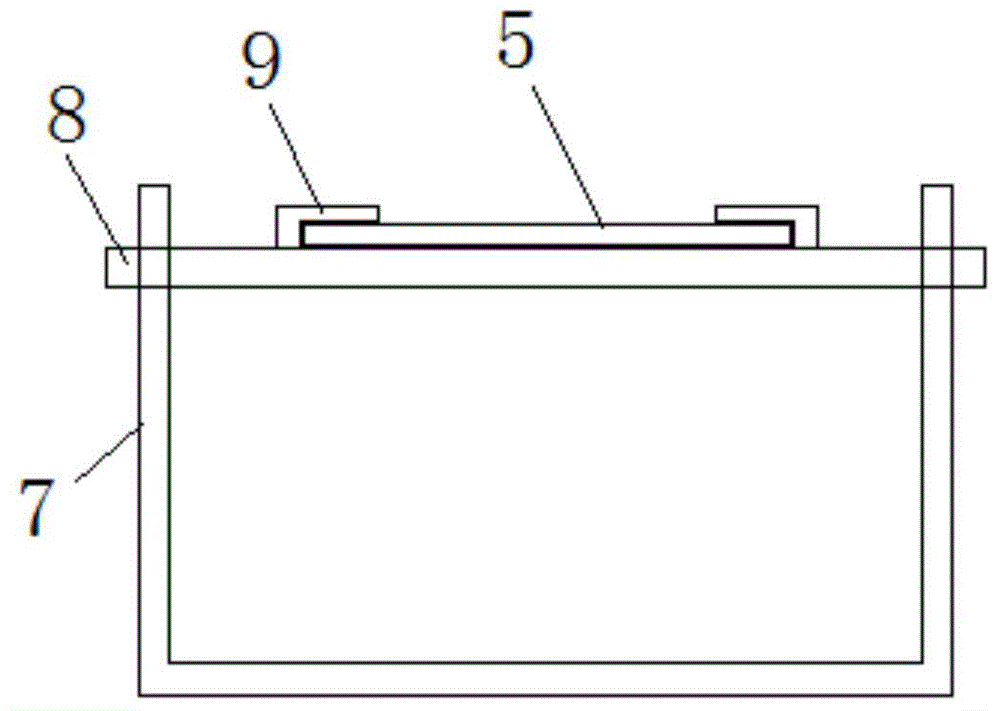

[0015] Such as figure 1 Shown is a method for testing the wear resistance of profile surface coatings using a falling sand testing machine. The falling sand testing machine includes a support frame 1, a sand holding funnel 2 arranged on the upper part of the support frame 1, and the discharge port of the sand holding funnel 2 is connected to the The upper end of the conduit 3 is connected, and a workpiece is arranged below the lower end of the conduit 3 . The inner angle of the sand-filling funnel 2 can be 60°, the discharge diameter can be 5mm, and the maximum capacity of the sand-filling funnel 2 is 7.5L. The sand filling funnel 2 is provided with a flow regulating valve 4 to control the leakage rate. By regulating the flow regulating valve 4, the flow of sand material leaking is controlled to reach a specified flow rate (can be 310g / min-330g / min). The workpiece should be cut on the decorative surface of the profile. When the sample cannot be directly sampled on the profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com