A connection structure between multi-core photonic crystal fiber and laser light source

A technology of photonic crystal fiber and connection structure, applied in the direction of multi-core fiber, cladding fiber, optical waveguide light guide, etc. Large transmission data capacity, easy splicing, and the effect of reducing the number of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

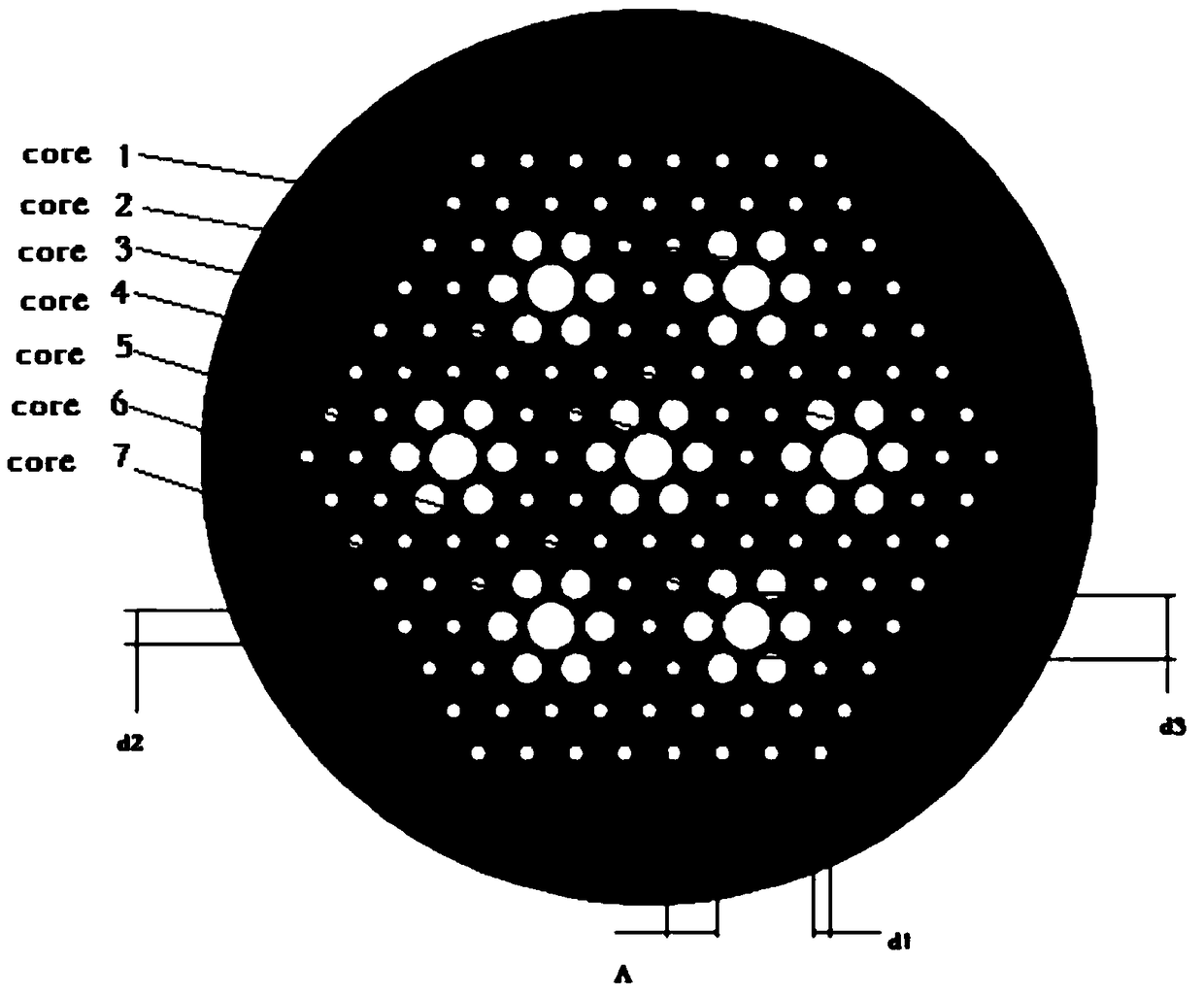

[0030] Such as figure 1 As shown, the core of the small-pitch multimode seven-core fiber is made of high-purity silica + F-doped low-refractive index glass, and each core is surrounded by 6 air claddings with a large duty cycle. All seven structures including the above-mentioned core and air cladding form a seven-core optical fiber in a centrosymmetric manner. The air holes are arranged in a positive hexamorphic array. The diameter of the small hole of the optical fiber is d1, the diameter of the six air holes with a large duty cycle is d2, the diameter of the fiber core is d3, and the distance between the small holes of the optical fiber is Λ. The range of d1 is 2.5-2.9um, the range of d2 is 5.5-6.4um, the range of d3 is 13-15um, and the range of Λ is 6.4-6.8um. From the point of view of the fiber core spacing, the distance between any two adjacent fiber cores is 25.6-28um. This design of fiber core spacing can correspond to the LED chip-level array layout, because corresp...

Embodiment 2

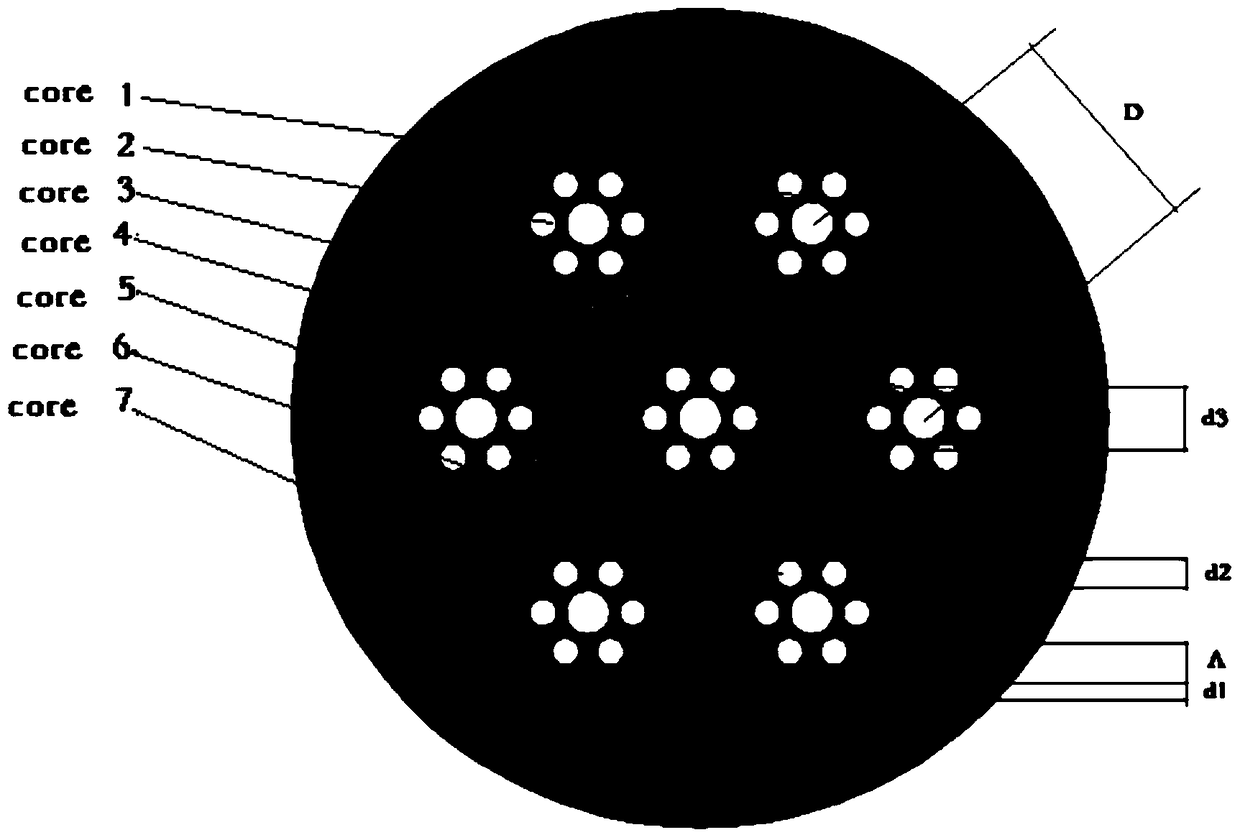

[0035] Such as image 3 As shown, the difference from Example 1 is that the range of Λ is 6.0-6.3um; from the point of view of the fiber core spacing, the distance between any two adjacent fiber cores is within the range of 36-37.8um. This design can be applied to Splicing VCSEL arrays or splicing LED arrays in the later stage. Because corresponding to the application of device-level light sources, it is also easy to realize a light source device array with a pitch in the range of 36-37.8um. This approach is flexible, convenient and more attractive to small integrators.

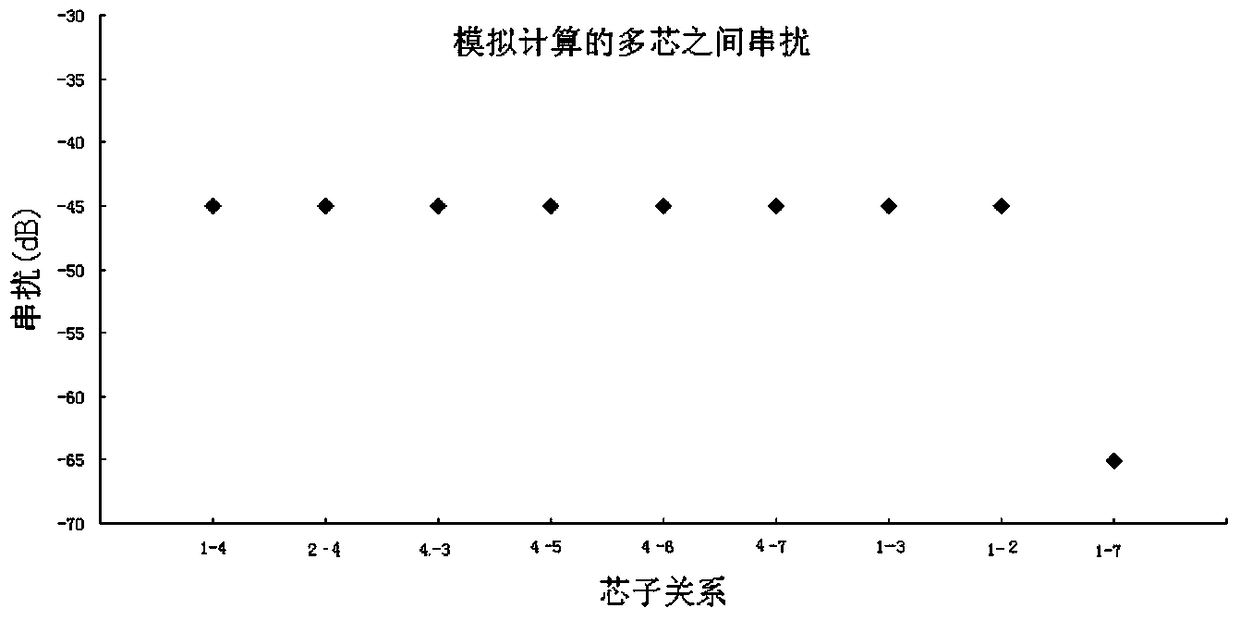

[0036] Such as Figure 4 As shown, it can be seen from the simulation calculation that the maximum crosstalk between the cores of the large-pitch multimode multi-core photonic crystal fiber is -60dB, and the mutual interference between multiple cores can be ignored in the design of the communication system.

Embodiment 3

[0038] Such as Figure 5 As shown, the hole diameter of the single-mode seven-core fiber is d1, the diameter of the six air holes with a large duty cycle is d2, the diameter of the fiber core is d3, and the hole spacing of the fiber is Λ. The range of d1 is 2.5-2.9um, the range of d2 is 5.5-6.4um, and the range of d3 is 9-10um. The range of Λ is 6.6-7.2um. From the point of view of the fiber core spacing, the distance between any two fiber cores is 41.6-42um. Each core of this 7-core single-mode fiber has a mode leakage channel, so it is very easy to form a single-mode transmission at any wavelength, which meets the requirements of high-speed, large-bandwidth short-distance data communication. Since the distance between the two cores exceeds 40um, the attenuation of high-order modes in the fiber mainly comes from material absorption and interface loss, so it is difficult for the energy of one core to propagate to the other. This design guarantees the single-mode transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com