Combination structure of electric connection between control unit and power supply unit

A technology of power supply unit and control unit, which is applied to the parts, connections, fixed/insulated contact components of the connection device, etc., which can solve the problems of helpless insulation and waterproof effect, excessive manufacturing and processing, and easy short circuit of the conductive sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

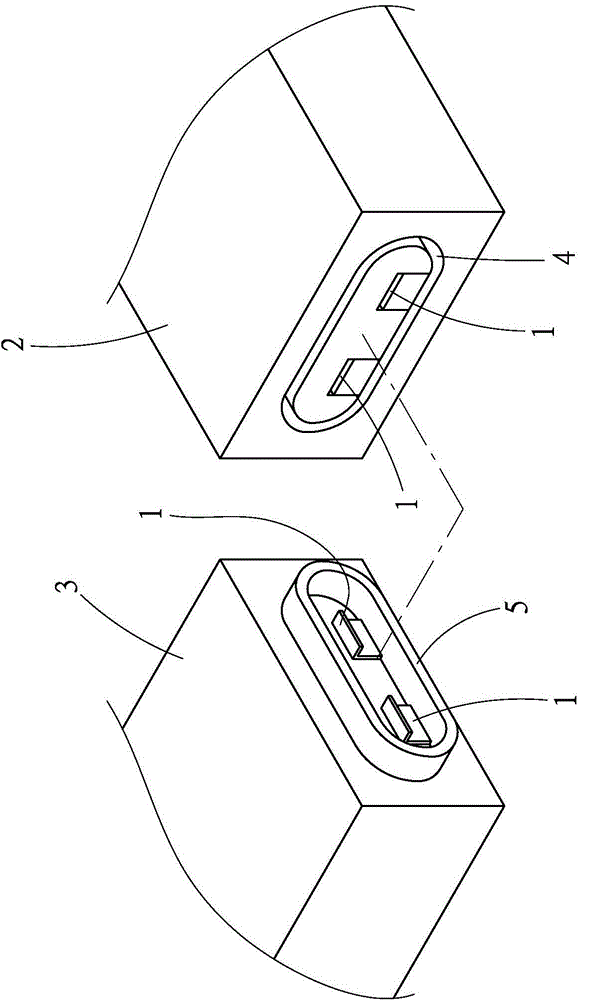

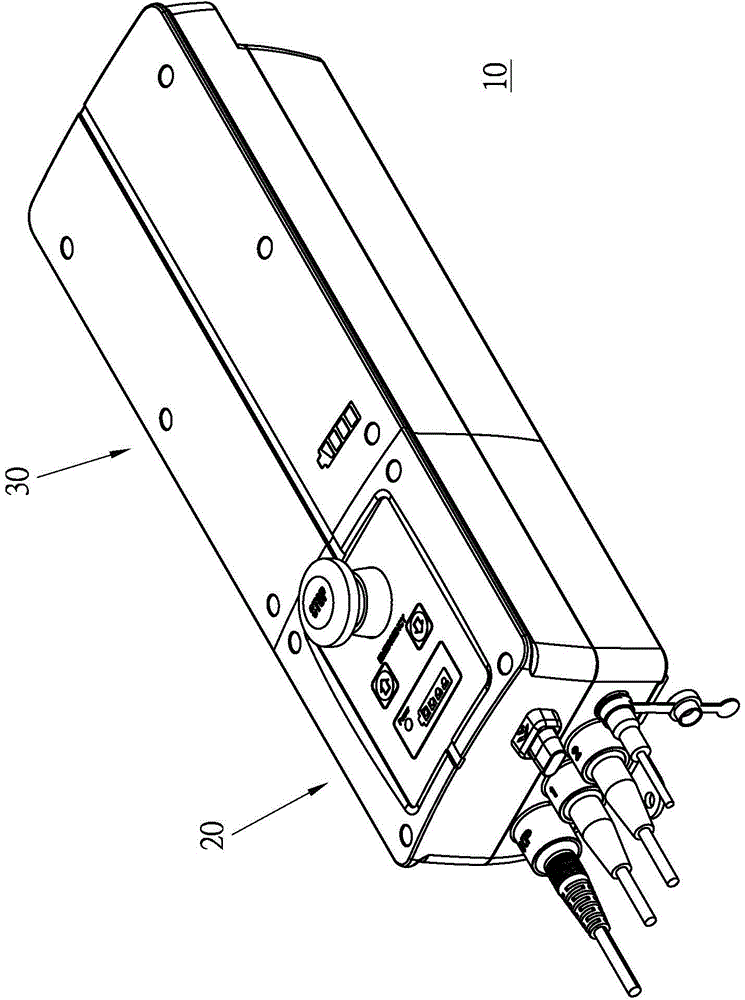

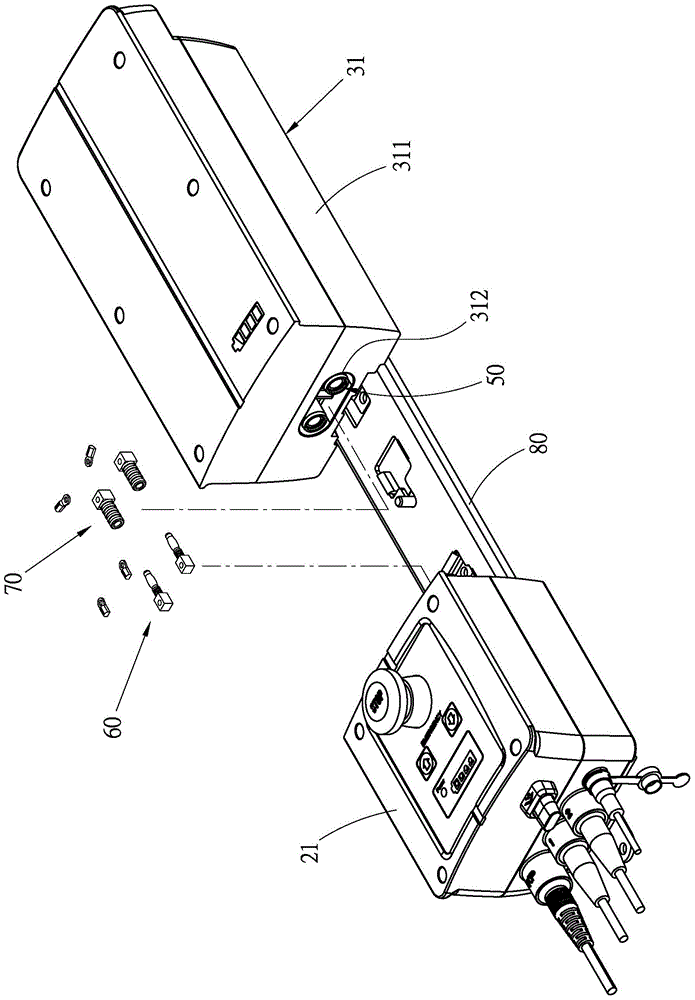

[0029] First, see Figure 2 to Figure 6 As shown, the combination structure 10 disclosed in a preferred embodiment of the present invention for the electrical connection between the control unit and the power supply unit mainly includes a first unit 20, a second unit 30, a first combination part 40, A second combining portion 50 , a first electrical connection portion 60 and a second electrical connection portion 70 .

[0030] The first unit 20 and the second unit 30 can be the control unit used to control the equipment as disclosed in the known technology and the power supply unit used to provide the control unit with electric energy, but they are used to achieve the control of the equipment and through the storage battery Providing electric energy and other technical content is not the technical feature of the present invention, so it will not be redundant here, but what should be explained is that the first unit 20 has a hollow first shell body 21, and the The second unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com