Heat pump dish washing machine and control method thereof

A control method and dishwasher technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, sustainable buildings, etc., can solve the problem of large dishwasher structure and unfavorable product miniaturization, etc. problems, to achieve the effect of benefiting product design, simple product structure, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

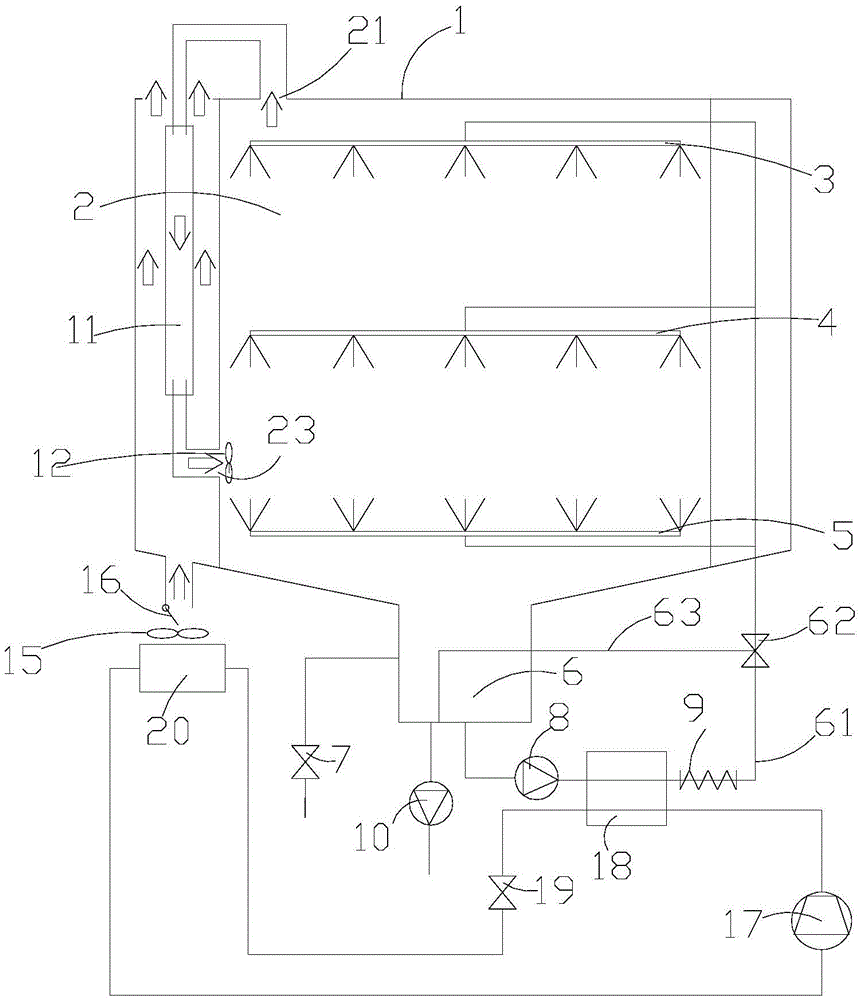

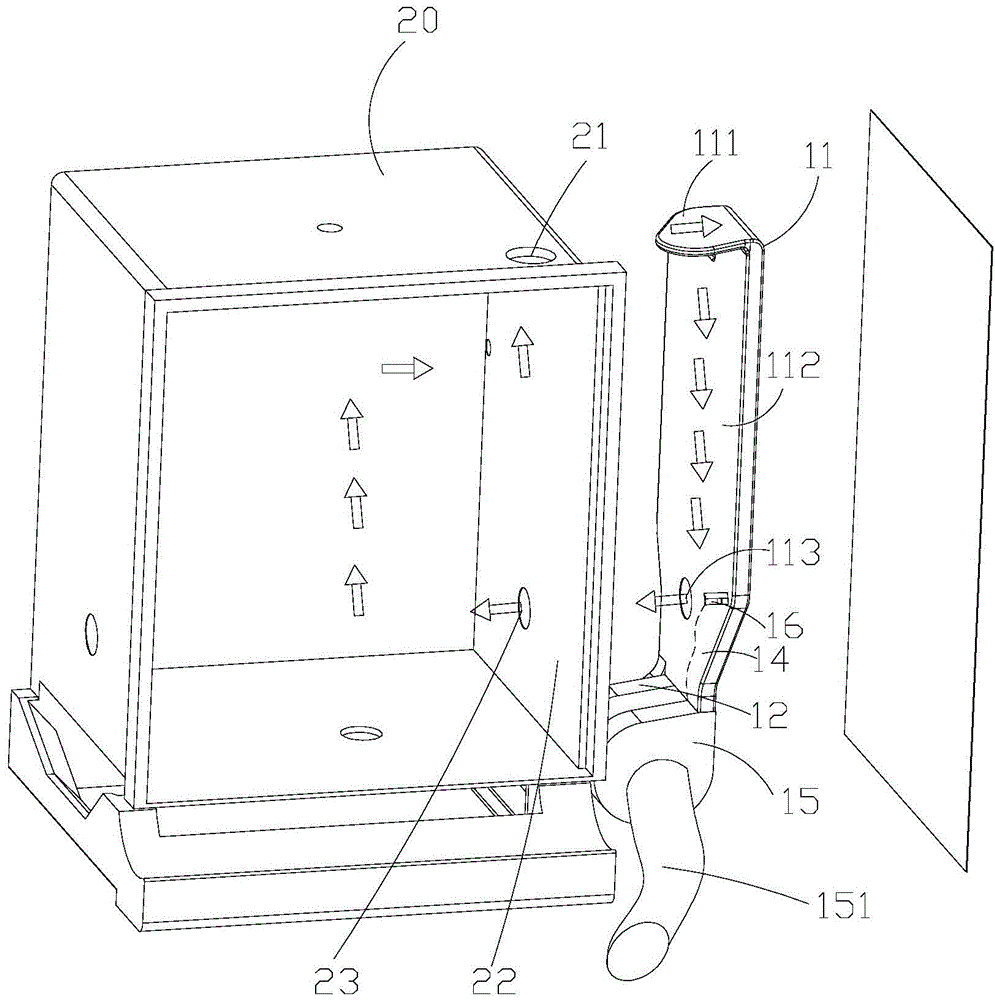

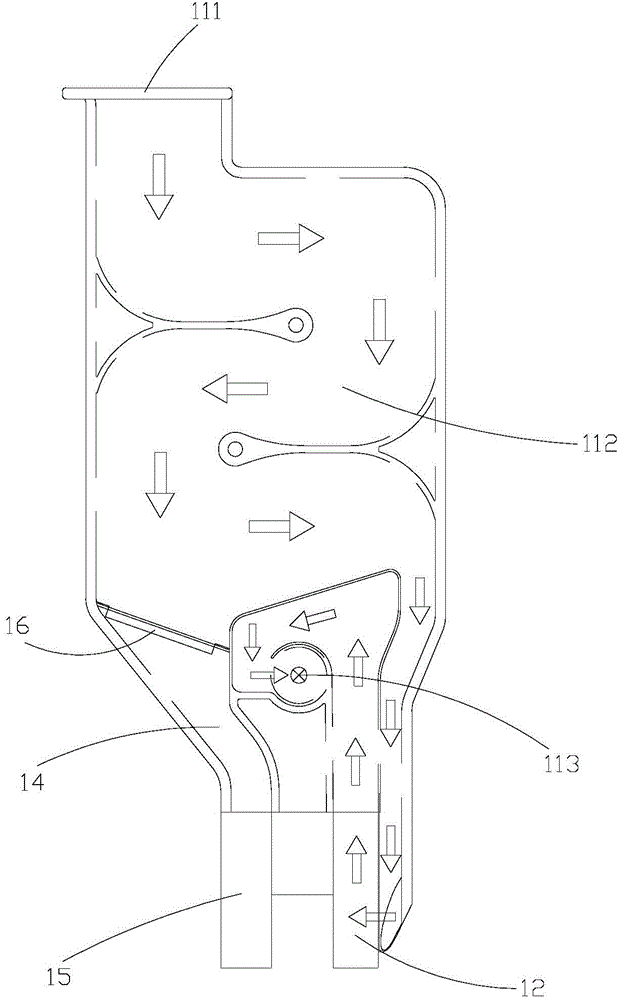

[0026] see figure 1 As shown, it shows a structural block diagram of an embodiment of the dishwasher of the present invention. Such as figure 1 As shown in , the dishwasher 1 of the present invention includes a dishwasher treatment chamber 2 for washing tableware, and an upper spray arm 3 , a middle spray arm 4 and a bottom spray arm 5 are arranged in the treatment chamber 2 . A water collection tank 6 is formed at the bottom of the treatment chamber 2, and a water inlet valve 7 communicates with the water collection tank 6, through which cleaning water can be injected into the water collection tank 6 of the treatment chamber. A circulating water pump 8 is communicated with the sump 6 , and the circulating water pump 8 pumps the cleaning water in the sump 6 into the upper spray arm 3 , the middle spray arm 4 and the bottom spray arm 5 . An electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com