A circular saw with a moving mechanism

A mobile unit, sawing machine technology, applied in metal sawing equipment, sawing machine devices, manufacturing tools, etc., can solve the problems of lengthening the sliding bar 16, affecting the sawing accuracy, increasing the thickness of the structure, etc., to improve the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

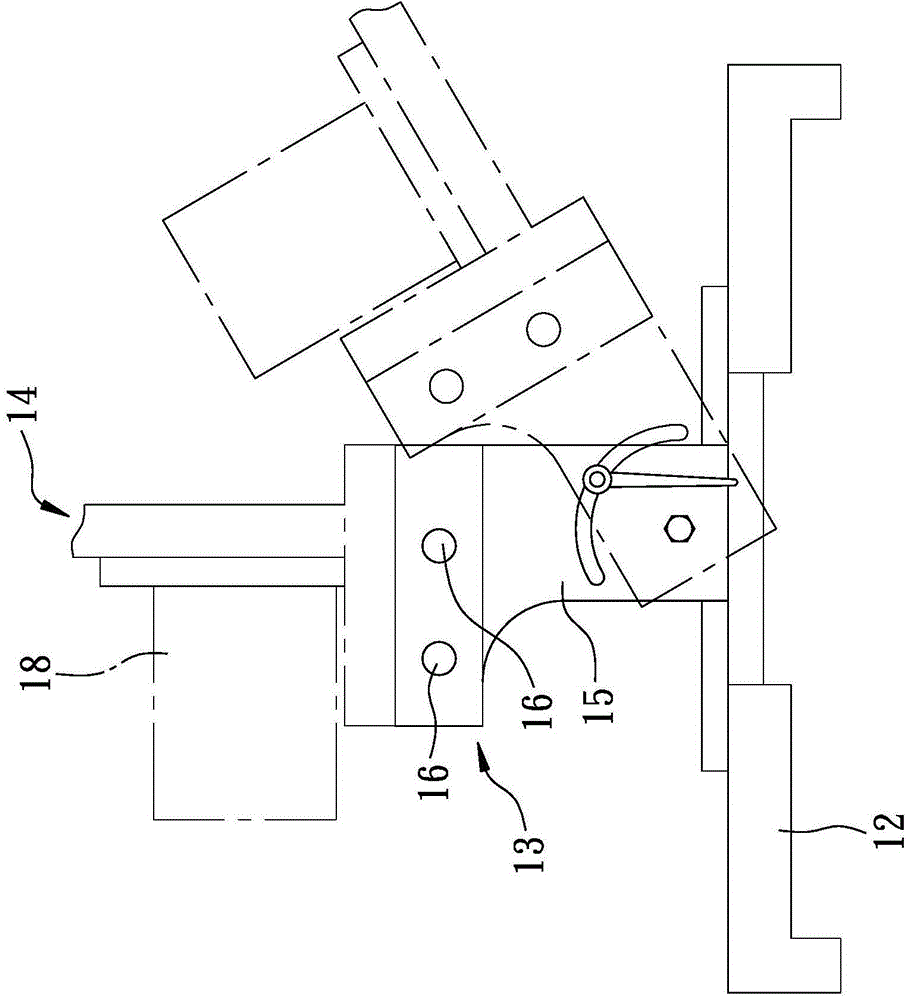

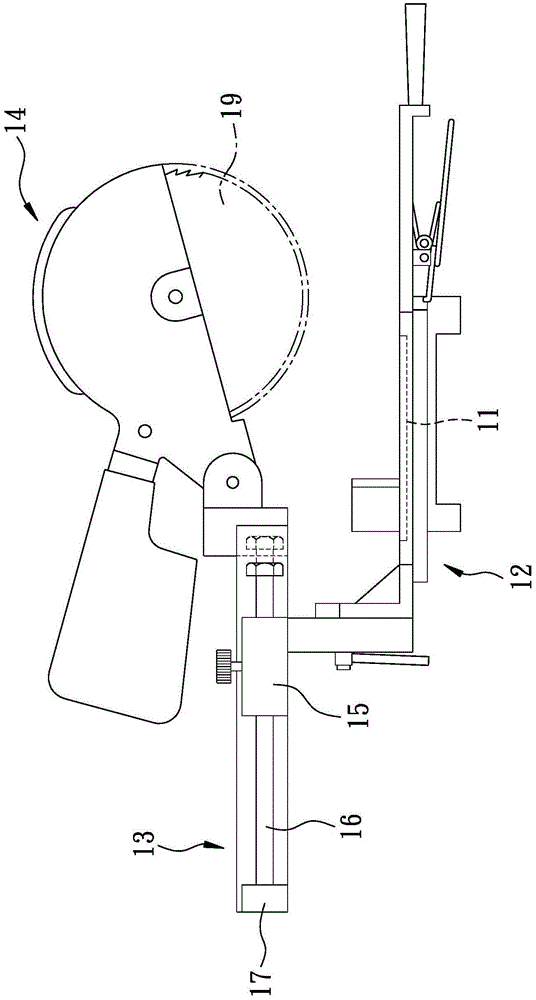

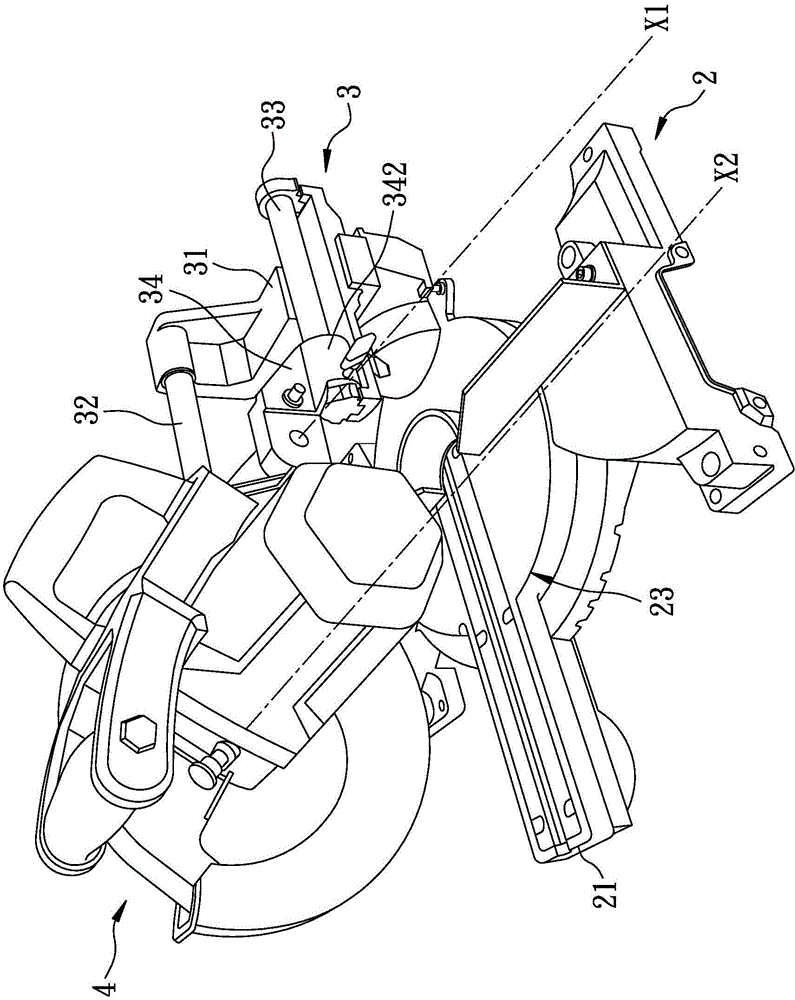

[0032] refer to image 3 , Figure 4 and Figure 8 , The preferred embodiment of the sawing machine with sliding unit of the present invention includes a carrier unit 2 , a moving unit 3 and a sawing unit 4 .

[0033] The carrier unit 2 includes a worktable 23 with a front side 21 and a rear side 22 opposite to each other, and a horizontal first plane F1 extending from the rear side 22 to the front side 21 .

[0034] The mobile unit 3 is located above the workbench 23, and includes a support base 31 arranged on the workbench 23, a first slide bar 32 and a second slide bar 33 respectively arranged in parallel and spaced on the support base 31, and A slide seat 34 is disposed on the first slide bar 32 and the second slide bar 33 .

[0035] In this embodiment, the first slide bar 32 is fixed on the support base 31 at the end far away from the sawing unit 4 (see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com