Vehicle wheel

A technology for wheels and vehicles, applied in the directions of wheels, vehicle parts, wheel cover discs, etc., can solve the problems such as the inability to sufficiently ensure the volume of the auxiliary air chamber and the formation of bulges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Next, embodiments of the present invention will be described in detail with appropriate reference to the drawings.

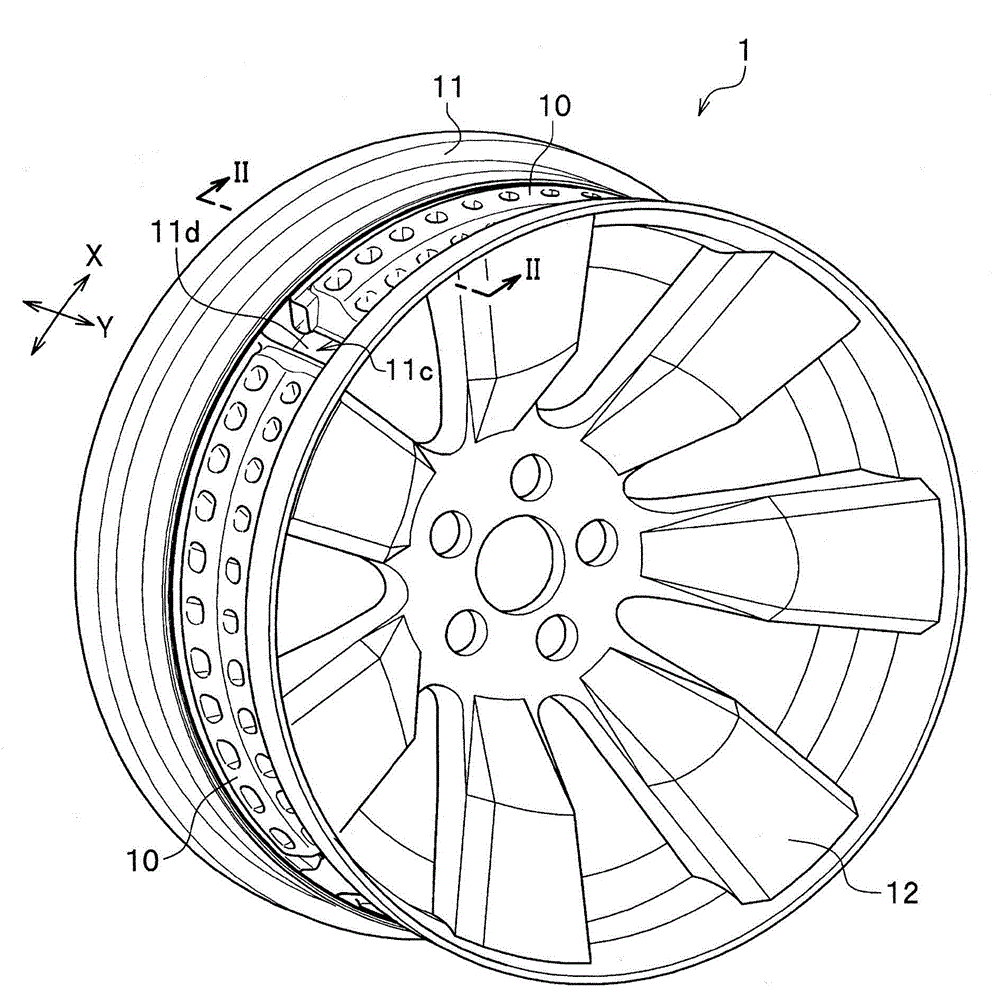

[0064] figure 1 It is a perspective view of the vehicle wheel 1 according to the embodiment of the present invention.

[0065] Such as figure 1 As shown, the vehicle wheel 1 according to the present embodiment has a plurality of sub-air chamber members 10 serving as Helmholtz resonators at equal intervals along the wheel circumferential direction X. In addition, in this embodiment, the case where there are four sub air chamber members 10 is assumed.

[0066] The vehicle wheel 1 of the present embodiment includes a rim 11 and a disc 12 for connecting the rim 11 to a hub (not shown). The sub air chamber member 10 is fitted and attached to the outer peripheral surface 11d of the well 11c in the rim 11 .

[0067] Hereinafter, the sub-air chamber member 10 will be described after describing the rim 11 .

[0068]

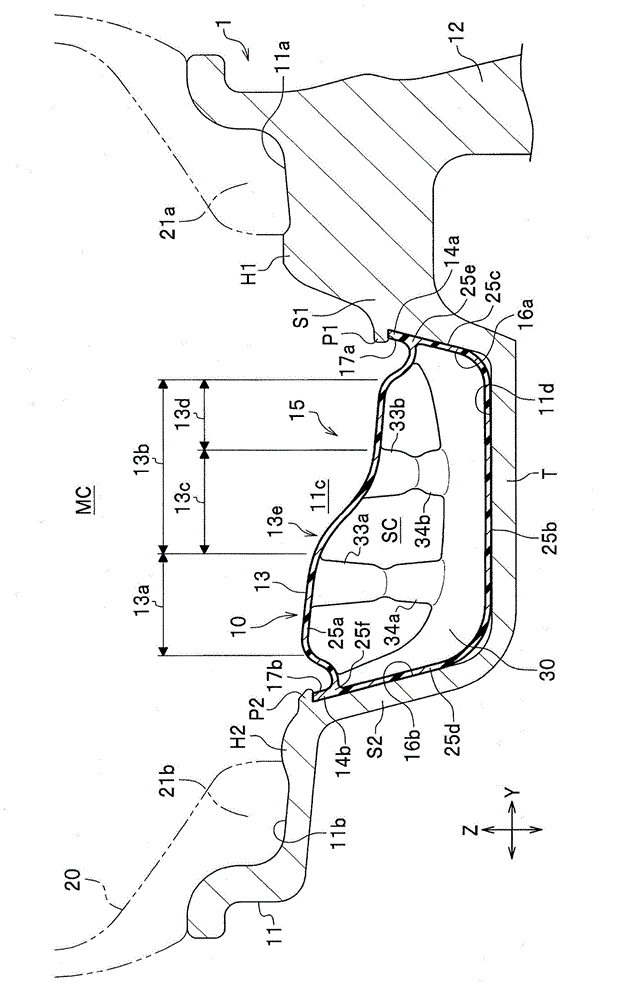

[0069] figure 2 yes figure 1 A parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com