Constant torque integral broken belt arresting device and its arresting method

A broken belt catching device and integrated technology, applied in the conveyor control device, transportation and packaging, conveyor and other directions, can solve the problems of many fault points, local bolt breakage, easy to produce malfunction and so on, to facilitate on-site construction. , Avoid secondary belt breakage and increase the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

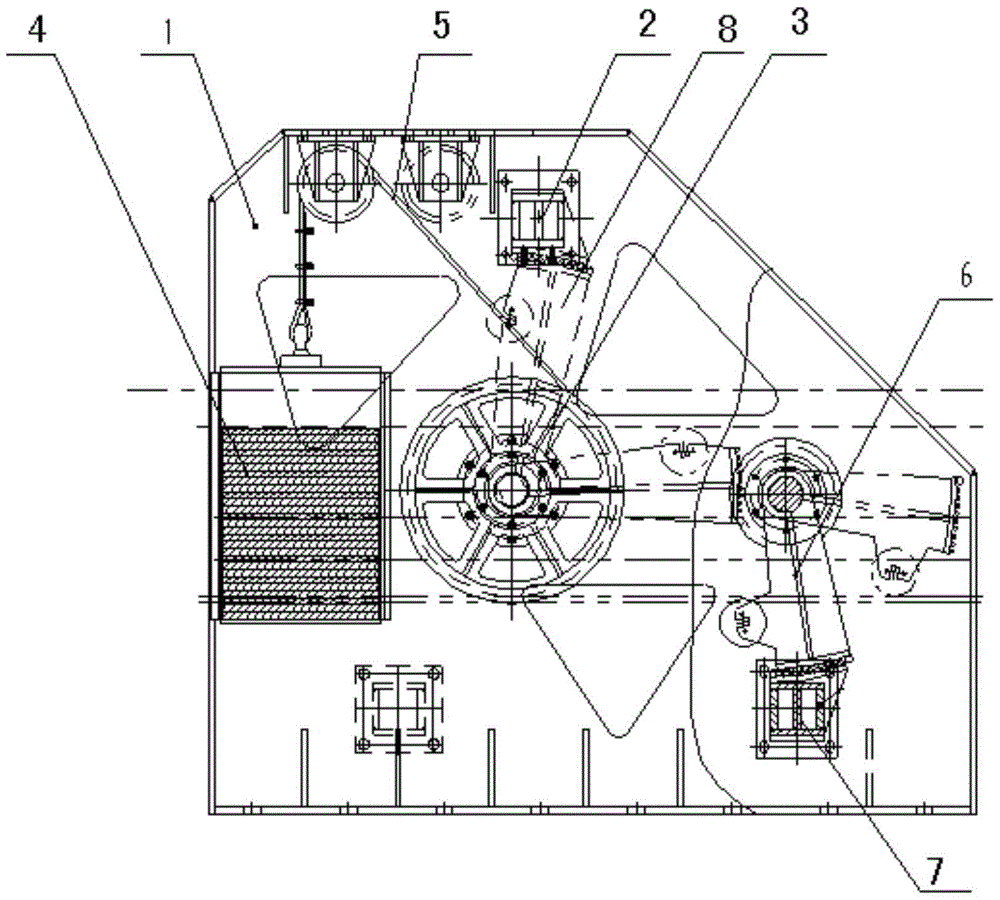

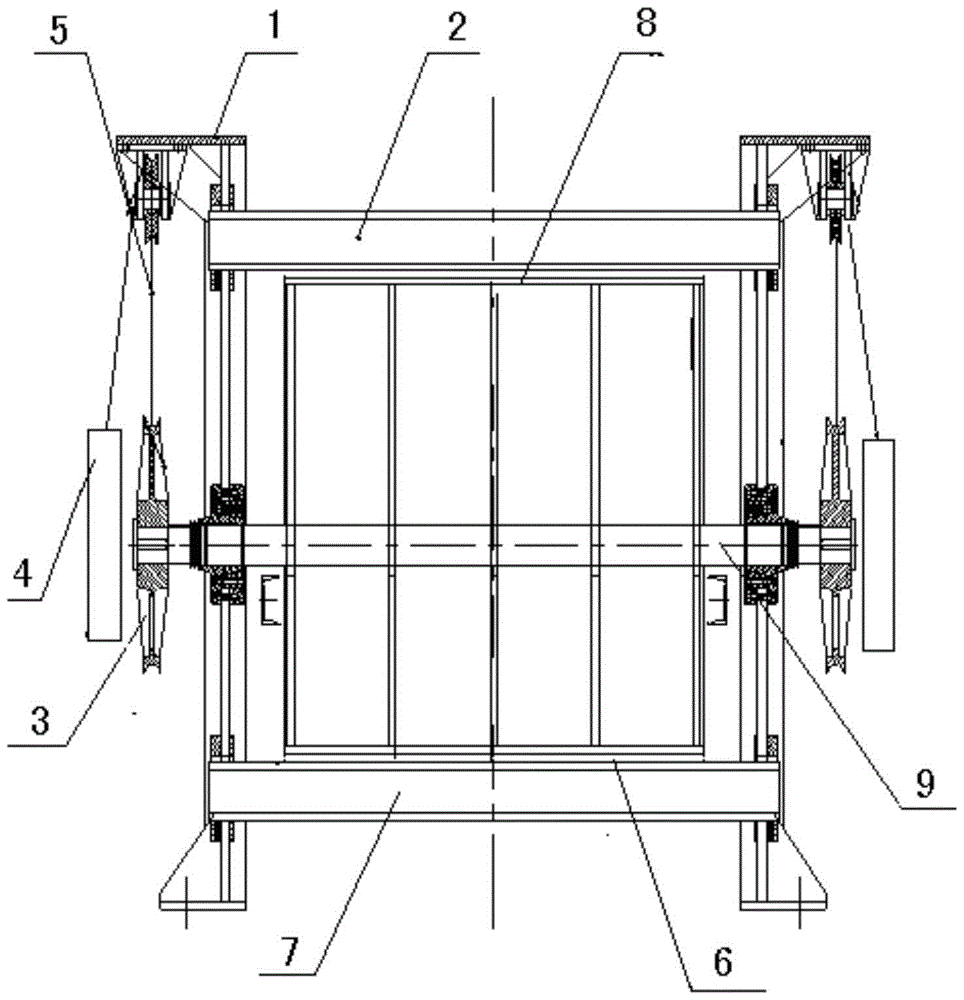

[0028] Such as figure 1 , 2 , shown in 3, a kind of constant torque integral type broken belt arresting device, it is made up of frame 1, upper crossbeam 2, lower crossbeam 7, rotating shaft 9, upper arresting frame 8, lower arresting frame 6 and driving system;

[0029] The frame 1 is a three-dimensional frame straddling the belt conveyor;

[0030] The upper beam 2 and the lower beam 7 are respectively fixed on the upper and lower parts of the frame 1, thereby forming a frame-type closed-loop structure;

[0031] The rotating shaft 9 traverses the middle of the frame 1 and is installed on the frame 1;

[0032] The upper capture frame 8 is installed on the rotating shaft 9, and the upper capture frame 8 rotates upwards and corresponds to the bottom surface of the upper beam 8. When the upper capture frame 8 rotates to the bottom surface of the upper beam 8, it can form a pair of conveyor belts. belt clamping force;

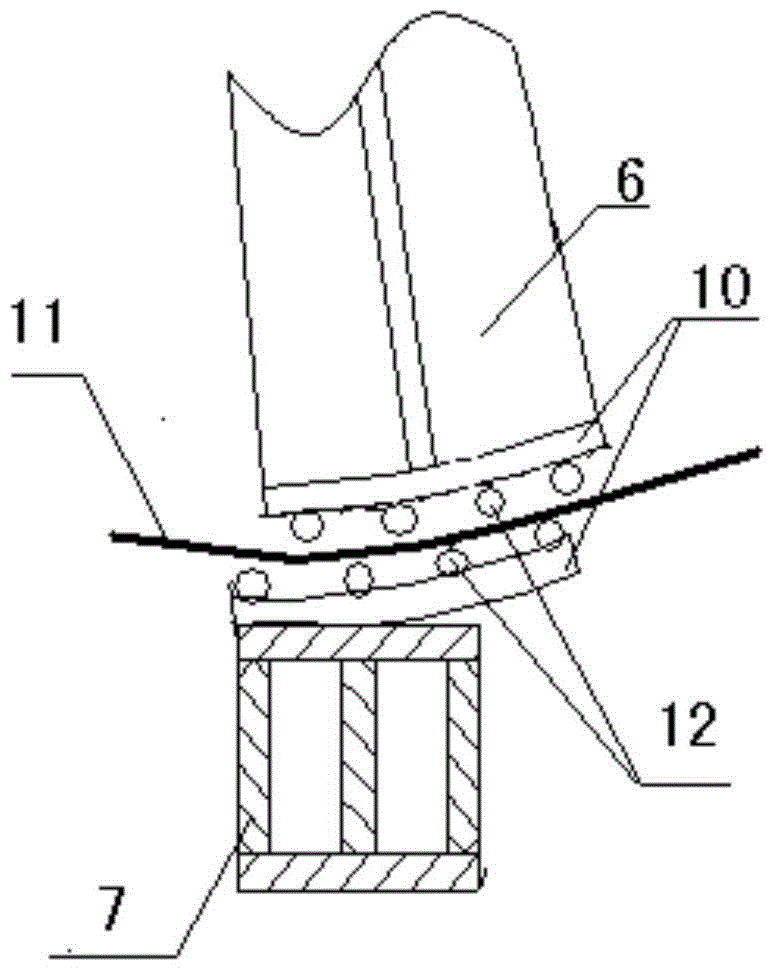

[0033] Described lower capture frame 6 is hinged on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com