A device for compounding and high-efficiency pressure filtration in the electrolytic manganese process

An electrolytic manganese and process technology, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems such as the inability to fully exert the working performance of the filter press, the working efficiency, the small flow rate of the pressure filtrate, and the increase of the pressure filtration resistance, etc. Achieve the effect of improving the dissolved oxygen capacity, reducing the dosage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with accompanying drawing, the present invention is described in further detail.

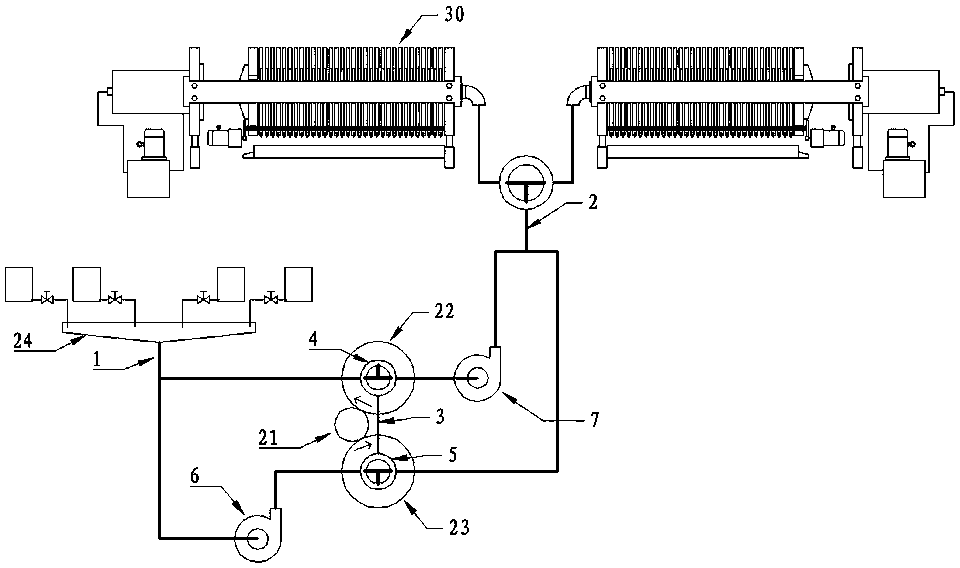

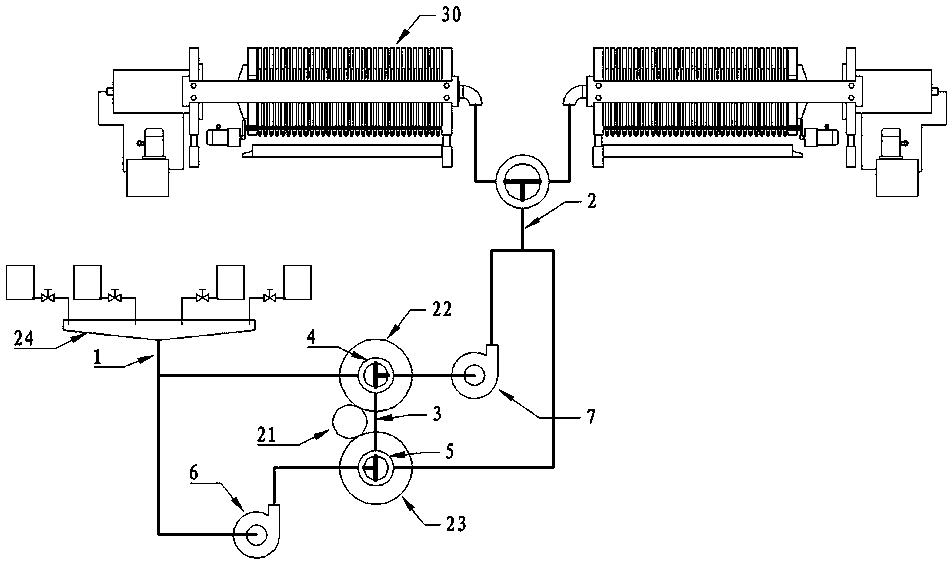

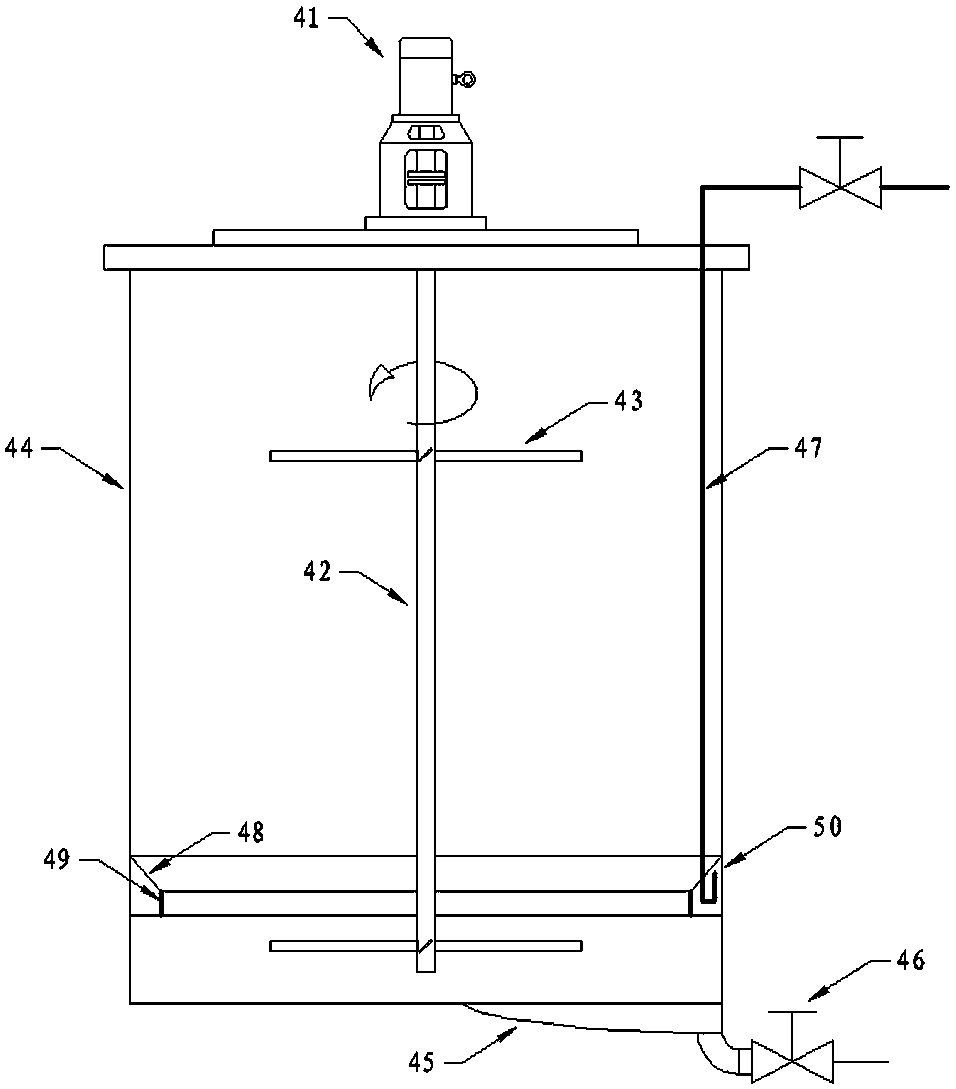

[0024] Such as figure 1 , figure 2 and image 3 The device for compounding and high-efficiency filtration in the electrolytic manganese process shown includes an inlet pipe 1, two centrifugal pumps (6, 7), an outlet pipe 2 and two filter presses 30, and the inlet pipe 1 is branched into two pipes, One pipe is connected to pipe 2 through three-way cock 4 and centrifugal pump 7, and the other pipe is connected to pipe 2 through another centrifugal pump 6 and another three-way cock 5; both three-way cocks 4 and 5 are equipped with gears 22 and 23 drive the spool to rotate, and a driving gear 21 is arranged between the gears 22 and 23 of the two three-way cocks to simultaneously drive the two three-way cocks 4 and 5 to rotate and switch. 3. Connect up and down; the inlet pipe 1 is connected to the manganese solution launder 24, and the launder 24 has an inverted conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com