Water transferring and oxygen dissolving machine

A technology of dissolved oxygen and water diversion, which is applied in fish farming, application, animal husbandry, etc. It can solve the problems of motor damage, large resistance, and heavy motor burden, and achieve the effect of reducing the cost of water leaves and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

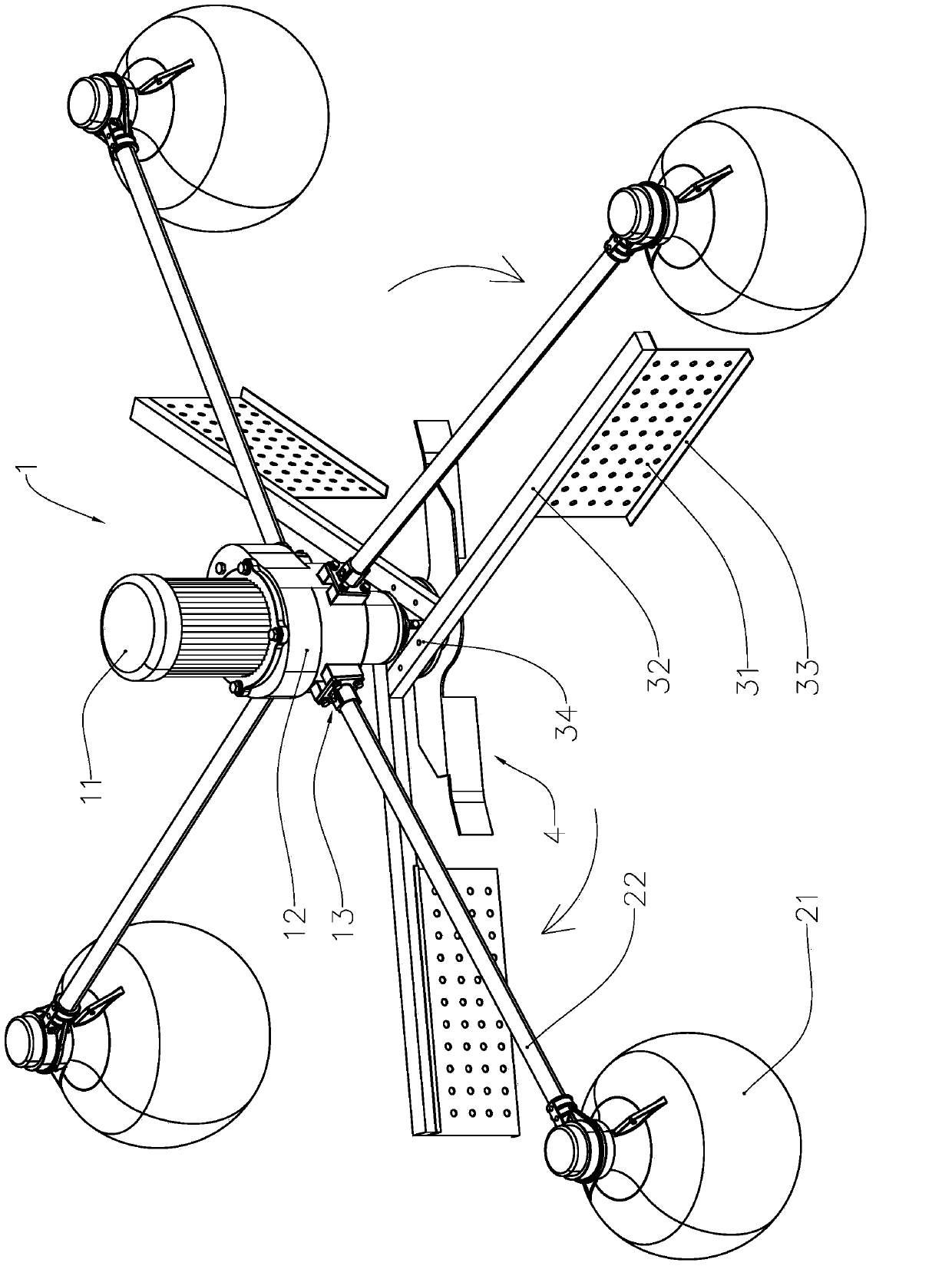

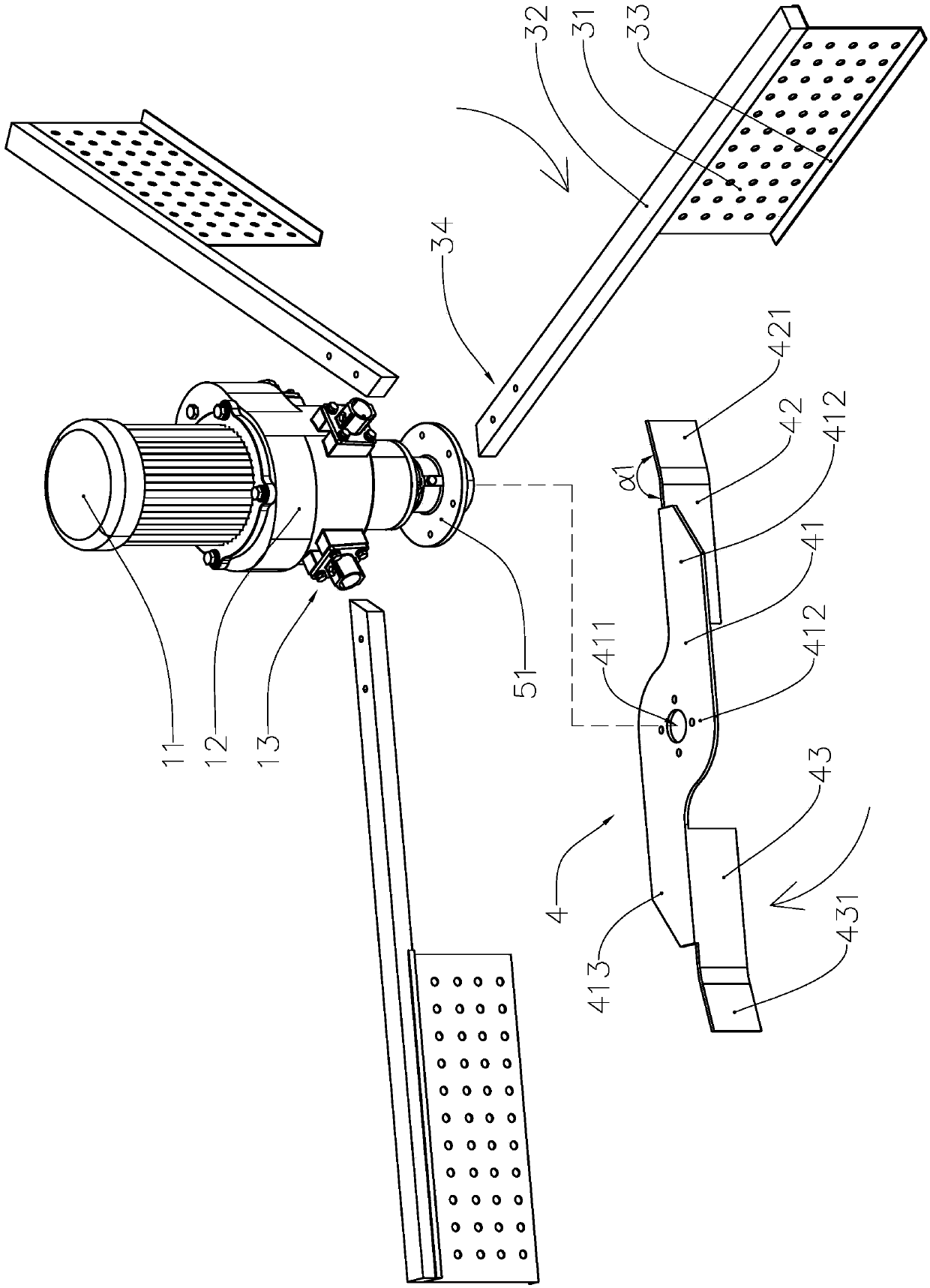

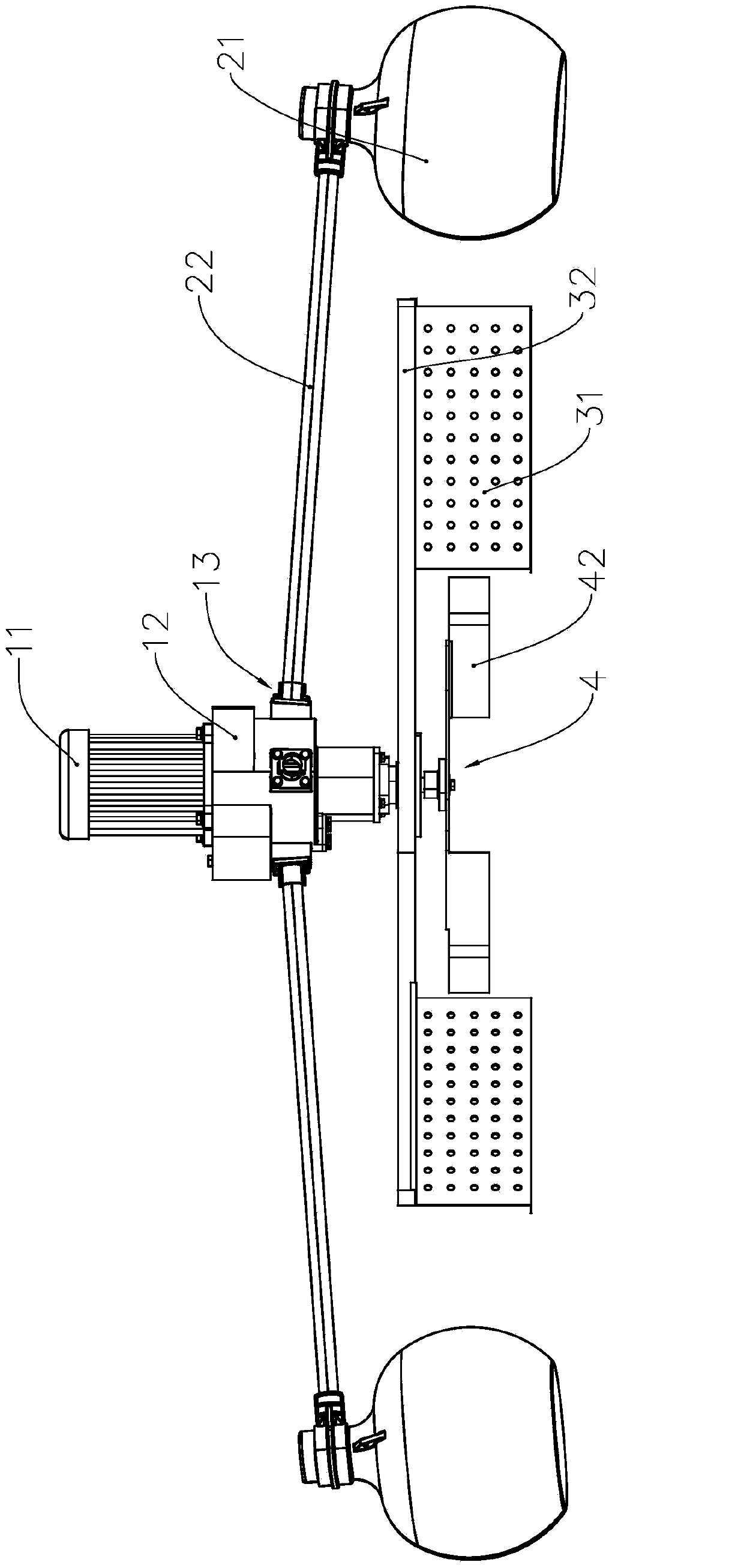

[0031] refer to figure 1 and figure 2 , figure 1 It is the structural diagram of the water adjusting and dissolving oxygen machine 1, figure 2It is an exploded view of the water adjusting and dissolving oxygen machine 1 after omitting the floating body. The water-adjusting and oxygen-dissolving machine 1 includes a motor 11 , a housing 12 , four floating bodies 21 , three water-adjusting plates 31 and water leaves 4 . A hollow cavity is formed inside the casing 12, and two openings are respectively formed on the top and bottom of the cavity, and the motor 11 is installed on the top opening, and the casing 12 is provided with four installation positions 13 on the outer wall, and the four installation positions The bits 13 are evenly distributed on the outer wall of the housing 12 along the circumferential direction.

[0032] Four floating bodies 21 are arranged outside the housing 12 of the water transfer and oxygen dissolving machine 1. The floating bodies 21 can be made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com