Magnetic type water-stop belt connector and construction method thereof

A technology of waterstop and magnetic suction, which is applied in the field of magnetic suction waterstop joints and its construction, and can solve the problems of damage to rubber waterstop joints, low operating efficiency, and unreliable construction methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

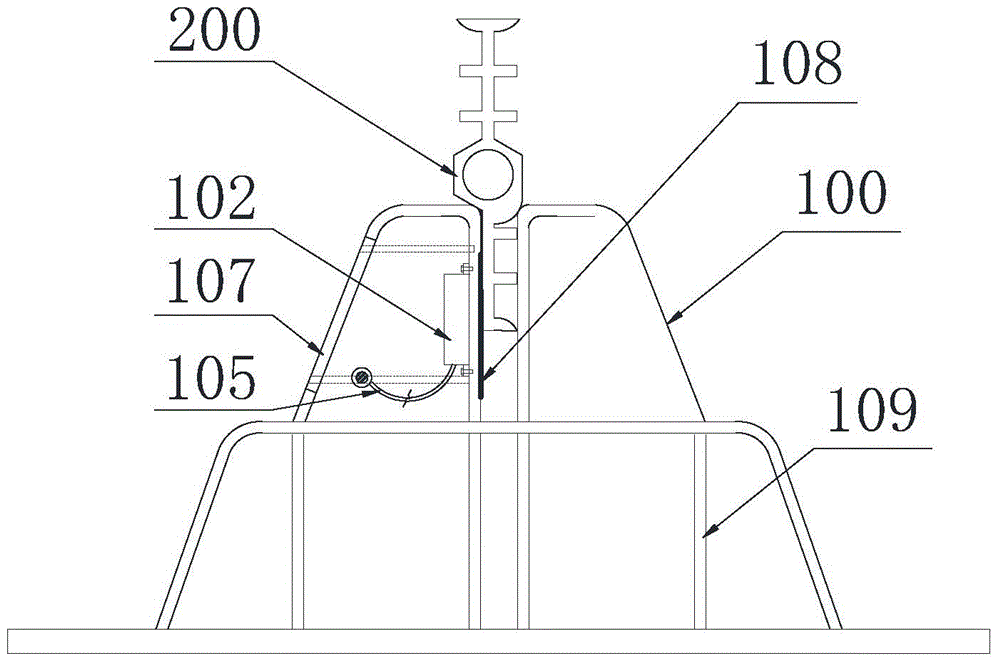

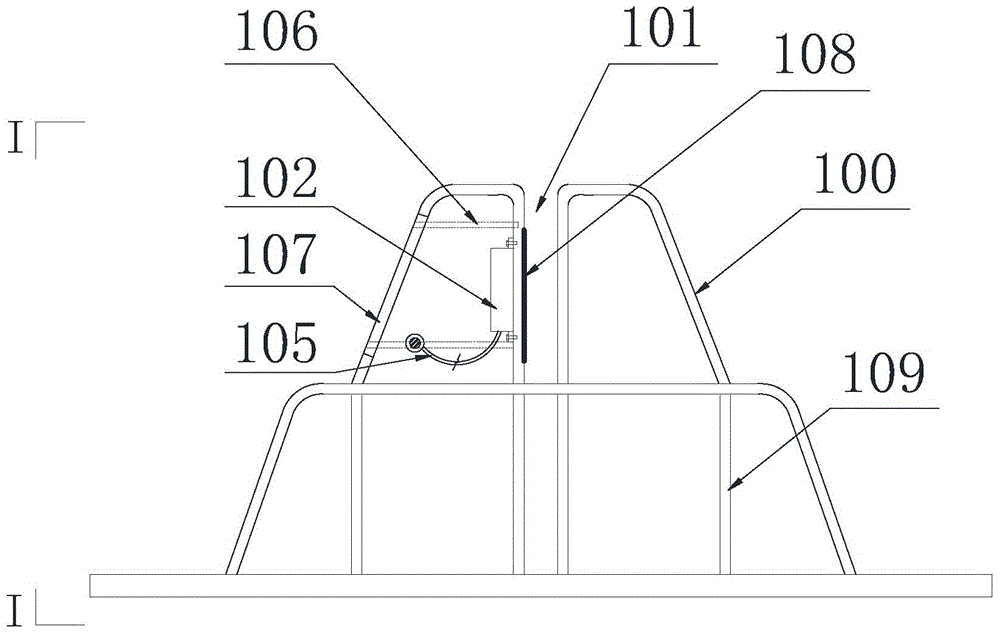

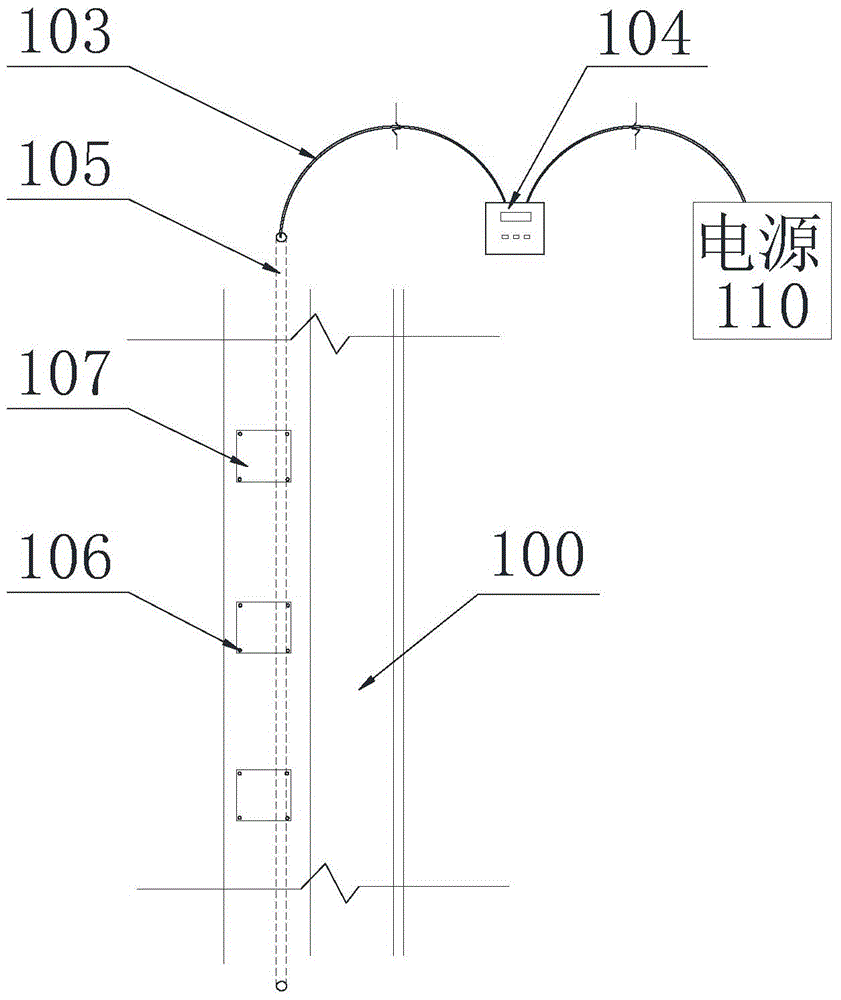

[0030] Please refer to Figures 1 to 5 , the first embodiment provides a magnetic suction waterstop joint, including a waterstop 200 and a joint box 100 made of magnetically conductive materials such as electrical pure iron or steel, and the waterstop 200 is inserted and connected to the joint box 100 In the bite 101 of the mouth, it also includes an electromagnetic fixing device for fixing the waterstop 200 and the joint box 100; the electromagnetic fixing device includes a plurality of uniformly distributed electromagnets 102, and each of the electromagnets 102 is magnetically For example, a magnetically conductive plate 213 made of a steel plate is connected, each of the electromagnets 102 is fixedly connected to the inner surface of the box body of the bite 101 of the connector box 100, and each of the electromagnets 102 is electrically connected to a switch through a wire 103 The controller 104 , the switch controller 104 is electrically connected to the power source 110 ...

Embodiment 2

[0039] The second embodiment provides a construction method for the magnetic waterstop joint of the first embodiment, which includes the following steps:

[0040] Step 1, disconnect all the electromagnets 102 of the electromagnetic fixing device from the power supply 110 through the switch controller 104, so that the electromagnets 102 are de-energized and no magnetic attraction force is generated;

[0041] Step 2: Hoist the joint box 100 with a crane, position it above the end of the excavated underground diaphragm wall’s front construction groove section, insert and fix the fixing unit 230 of the waterstop 200 into the bite of the joint box 100 within 101;

[0042] Step 3: Slowly lower the joint box 100 into the front construction groove section, and at the same time insert the rubber water-proof connecting belt unit 220 and the rubber water-stop belt unit 210 of the waterstop 200 into the bite of the sinking joint box 100 101, when the rubber waterstop unit 210 at the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com