A leak-proof water inlet valve

A water inlet valve, anti-leakage technology, applied in valve details, valve devices, water supply devices, etc., can solve the problems of adding sliders and baffles, inability to separate, affecting the normal operation of the water inlet valve, etc., to reduce high precision requirements. , Simple structure, stable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

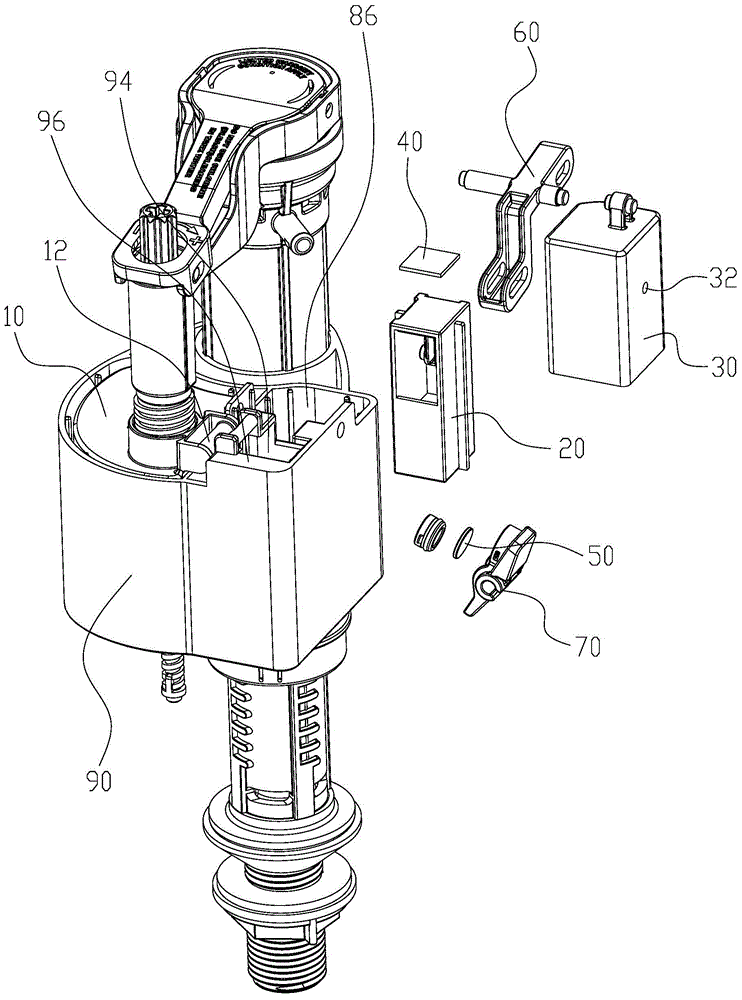

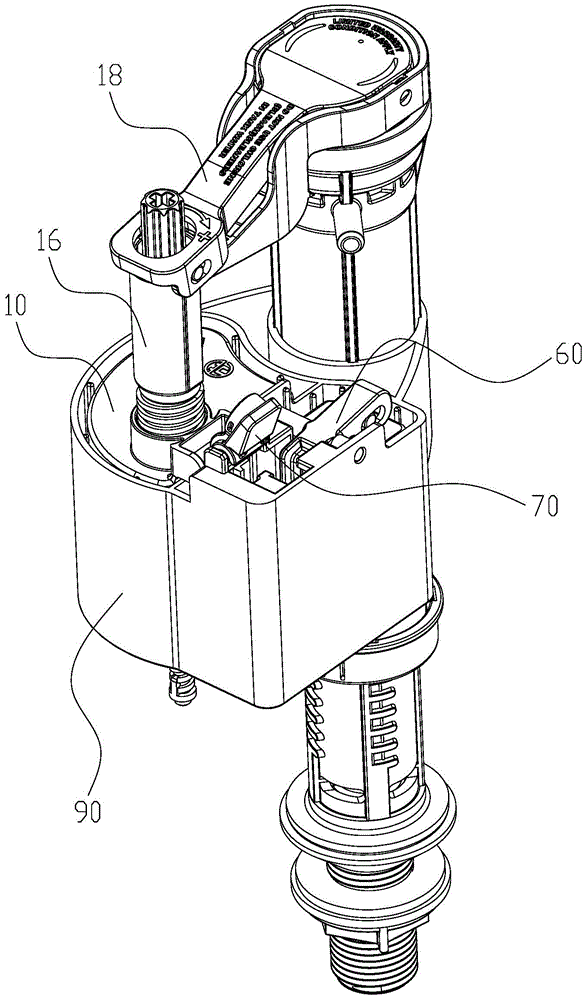

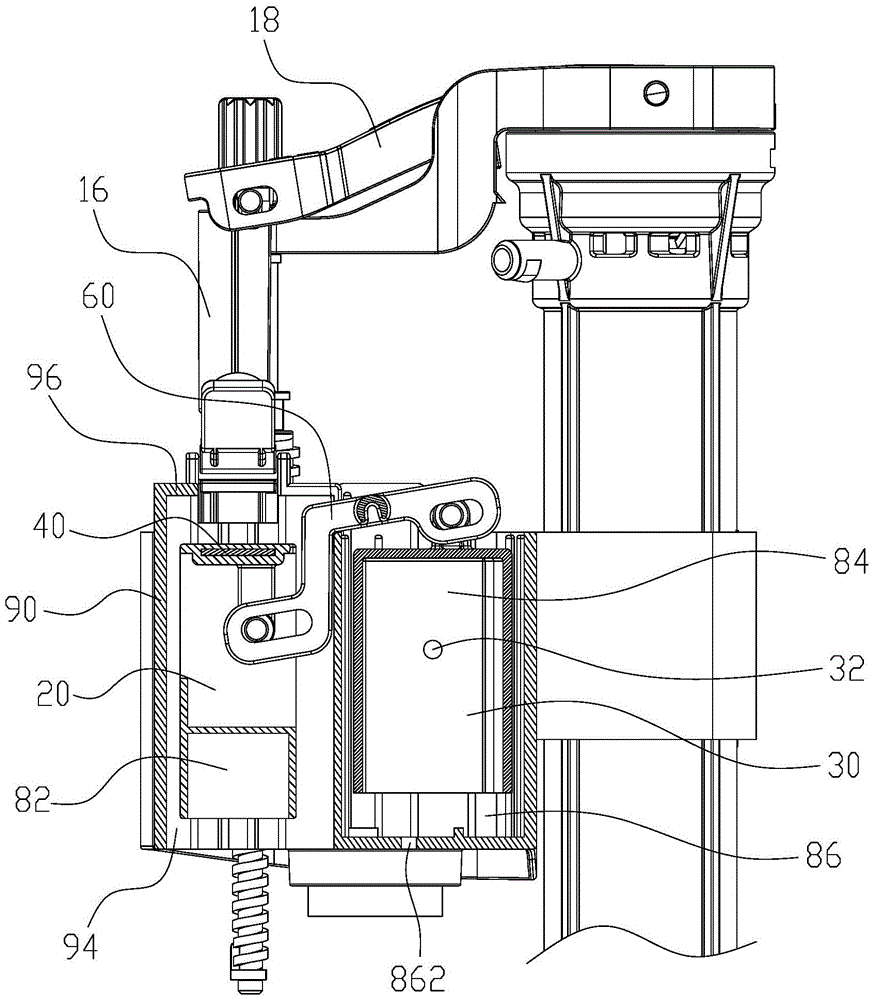

[0035] Please refer to figure 1 with figure 2 , a leak-proof water inlet valve of the present invention, comprising a water inlet valve control mechanism movably mounted on the water inlet valve, a floating bucket adjustment mechanism, a first magnetic piece 40 and a second magnetic piece 50, the first magnetic piece The suction part 40 is connected to the floating bucket adjustment mechanism by transmission, and the second magnetic suction part 50 is connected to the water inlet valve control mechanism by transmission. The first magnetic suction part 40 and the second magnetic suction part 50 are magnetically matched; A magnetic attraction 40 is far away from the second magnetic attraction 50; when the water tank leaks, the floating bucket adjustment mechanism drives the first magnetic attraction 40 close to the second magnetic attraction 50 and magnetically cooperates with the second magnetic attraction 50.

[0036] In this embodiment, the water inlet valve control mechani...

Embodiment 2

[0046] Please refer to Figure 7 to Figure 10 The difference between the second embodiment and the first embodiment is that: the outer side of the water stop cup 90a is provided with a first storage chamber 86a and a second storage chamber 94a which are arranged side by side and open up and down, and the control float 30 is arranged in the first storage chamber 86a. The leak-proof floating bucket 20 is arranged in the second storage chamber 94a; a counterweight chamber 88 is arranged on the leak-proof floating bucket 20, and a drain hole 882 is provided at the bottom of the counterweight chamber 88; the first seesaw bar 60a is V-shaped A connecting rod 14 is connected to the water-stop floating bucket 10a, and the connecting rod 14 is pivotally connected to the end of the second seesaw rod 70.

[0047] When the water tank is filled with water: at this time, the water tank is empty or the water level is very low, and the leak-proof floating bucket 20 is in a falling state under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com