a wind brace

A technology for wind bracing and positioning components, which is used in buildings, building fastening devices, and wing sash fastening devices, etc., which can solve problems such as being hard to be blown by strong winds, reducing the overall strength of window sashes, and positioning the wind bracing thickness and thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

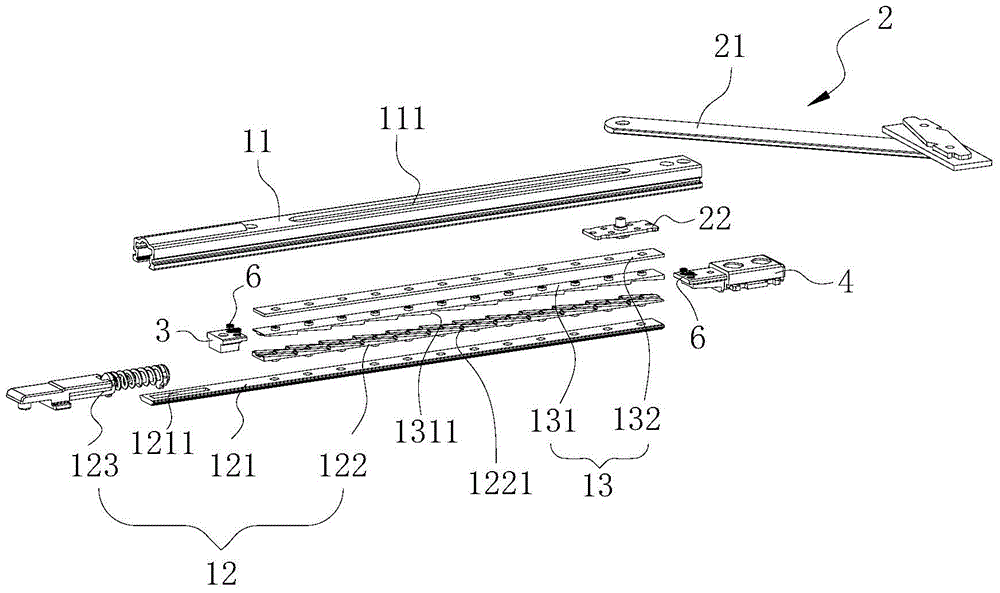

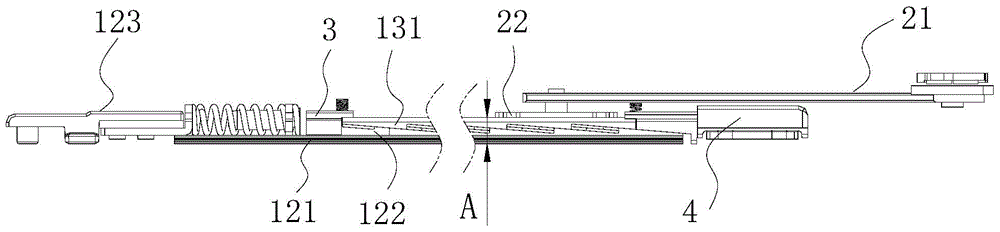

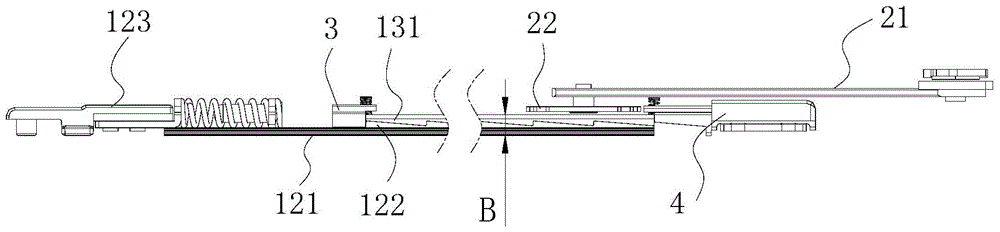

[0033] Attached below Figure 1 to Figure 7 and Figure 11 The technical solutions of the present invention are further described through specific implementation methods.

[0034] Such as figure 1 and Figure 4 As shown, a positioning wind brace includes a wind brace positioning assembly 1, and a connecting rod assembly 2 connected with the wind brace positioning assembly 1, the connecting rod assembly 2 includes a connecting rod 21, and is connected with the connecting rod One end of 21 is pivotally connected to the sliding piece 22; the wind brace positioning assembly 1 includes a slide rail 11 for sliding the slide piece 22, a handle transmission piece 12 slidingly matched with the slide rail 11, and a The handle transmission part 12 cooperates with the extruding part 13 for the sliding part 22 to stop sliding; the setting of the extruding part 13 can form a certain friction force with the sliding part 22, and then play a role in the positioning of the window sash. Eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com