A hydraulic cylinder lateral force loading device for simulating working conditions

A technology of loading device and hydraulic cylinder, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc. It can solve problems such as not conforming to actual working conditions, achieve perfect detection technology, and facilitate adjustment and disassembly , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

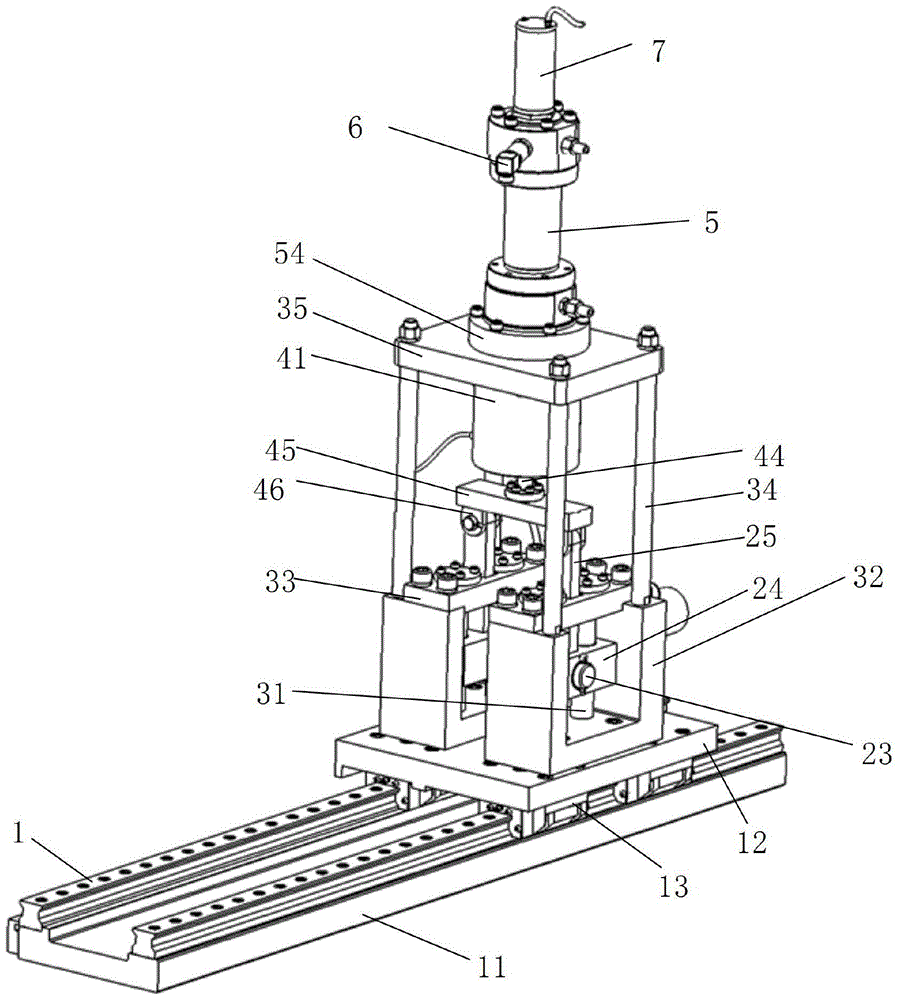

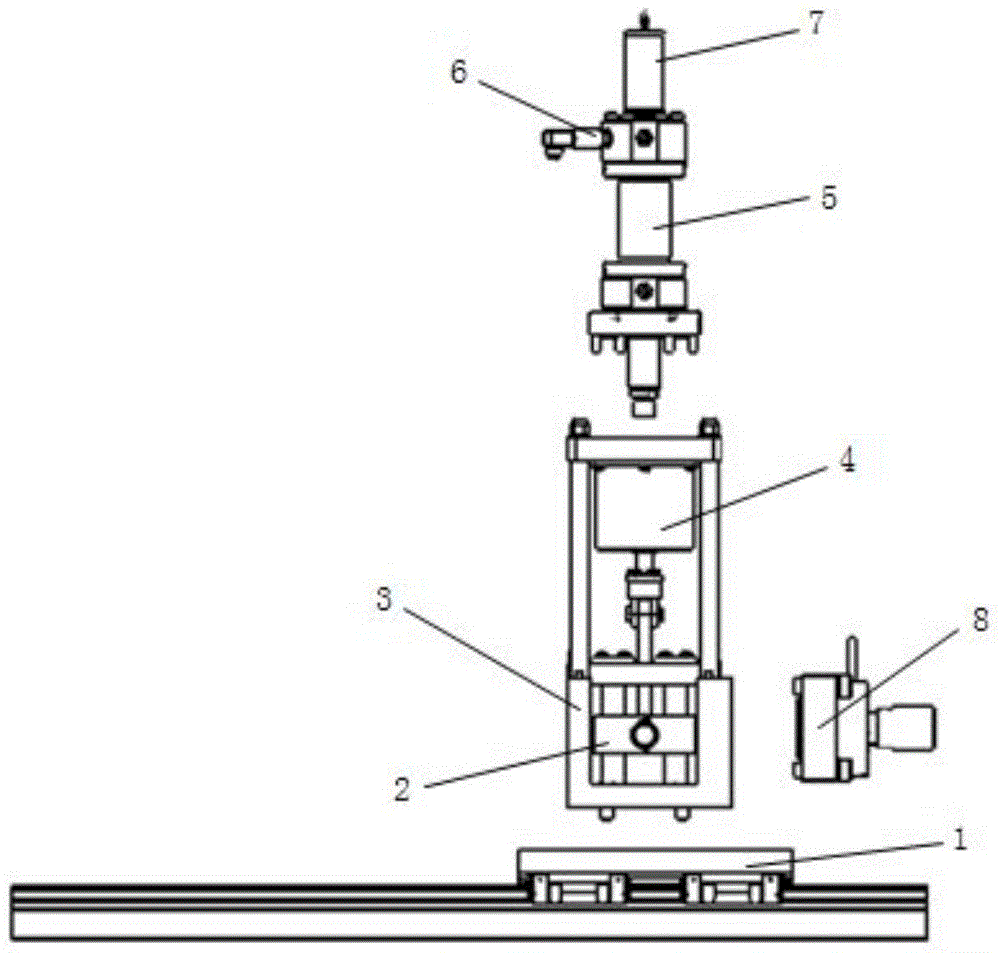

[0027] to combine figure 1 and figure 2 , a hydraulic cylinder lateral force loading device for simulating working conditions, including a linear guide rail 1, a sliding seat 2, and a fixed seat 3, the linear guide rail 1 is welded on the bottom surface 11 of the guide rail installation, and the guide rail base 12 fixes the slider 13 by bolts Under the platform, for linear motion along the linear guide rail 1, the fixed seat 3 is arranged on the guide rail base, the earring of the piston rod extension end of the hydraulic cylinder under test is fixed on the sliding seat 2, and the sliding seat 2 is arranged on the fixed seat 3 and The sliding seat 2 moves in a direction perpendicular to the linear guide rail 1; external forces act on the fixed seat 3 and the sliding seat 2 respectively to apply axial force and lateral force to the piston of the hydraulic cylinder under test.

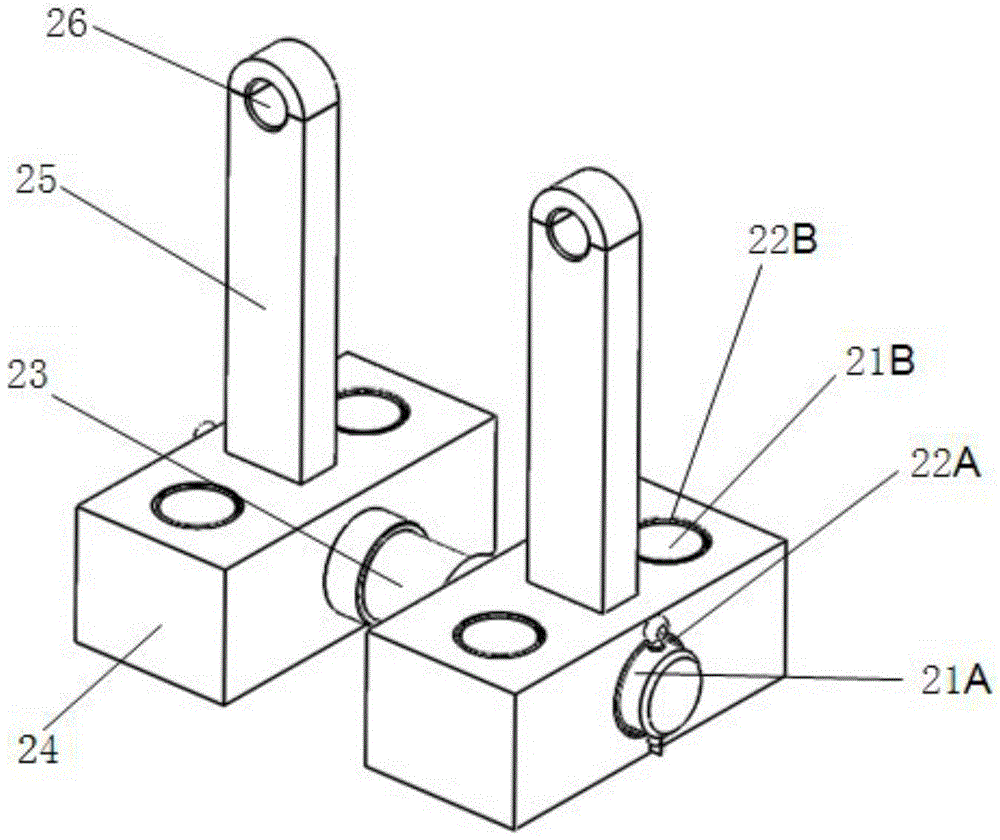

[0028] to combine image 3 In order to realize that the sliding base 2 moves in a direction perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com