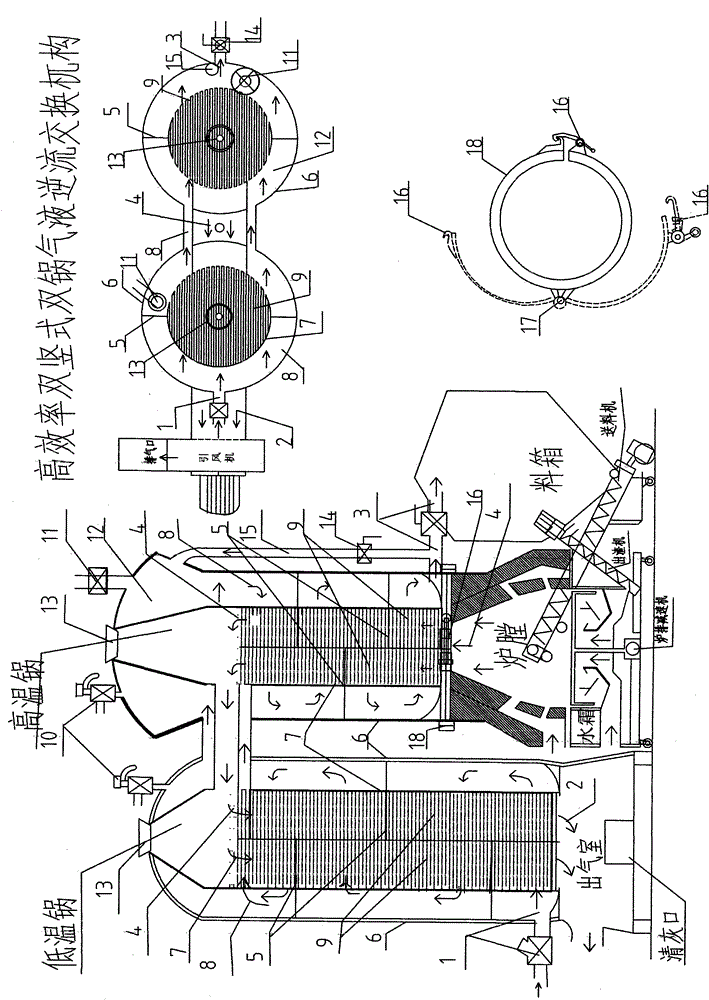

High-efficiency double-vertical-pot gas-liquid reverse-flow exchange mechanism

A countercurrent exchange, double-vertical technology, applied in steam boilers, fluid heaters, steam generation, etc., can solve the problems of energy recovery, increased pollutant emissions, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] As shown in the figure, the high-efficiency double-vertical double-boiler gas-liquid countercurrent exchange mechanism designed by the present invention (1) The liquid temperature of the inlet valve liquid inlet is the lowest point, which is connected to (6) the lower position of the outer wall of the pot, ( 6) The bottom of the outer wall of the pot is connected to (2) the upper end of the outer wall of the air outlet, (2) the upper end of the air outlet is connected to the low-temperature pot, the bottom is the dust box and the machine foot, and the side is the exhaust pipe. The cold liquid passes through (1) and enters the lowest level (9) gas-liquid fork exchange tube, and is guided by the design of the horizontal isolation plate (5). Enter, pass through the upper end of the exchange pipe and then advance downward in turn, reach (4) the fire smoke port and pass through the exchange pipe at the lower end of the high-temperature pot, and output to the position of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com