Thin plate side wall smoothness detection device

A detection device and flatness technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of not being able to display the specific situation with images, troublesome operation, etc., and achieve convenient replacement of pencil heads, stable structure, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

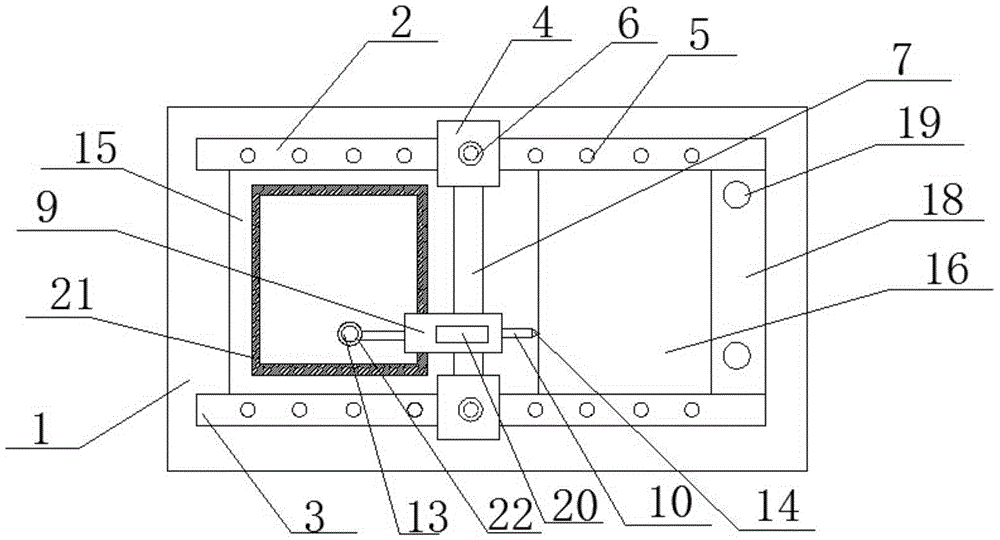

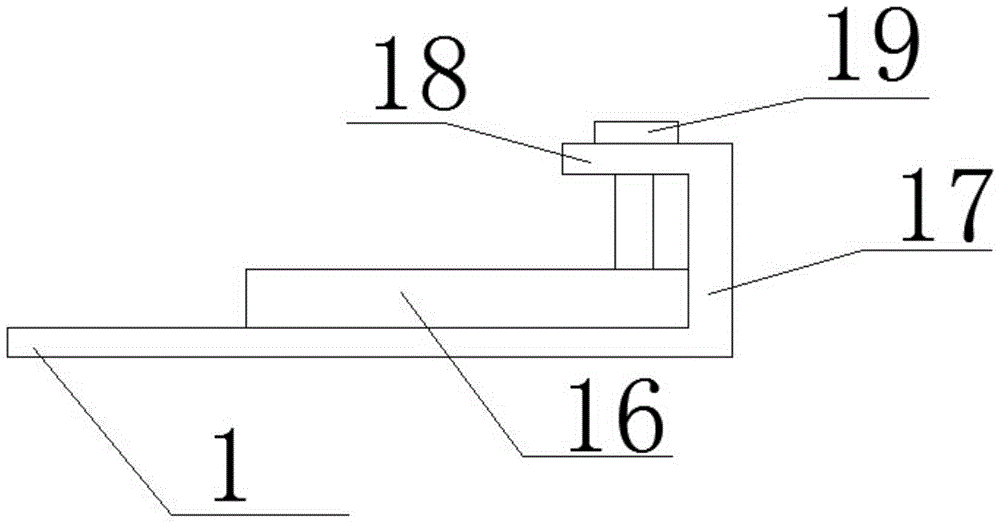

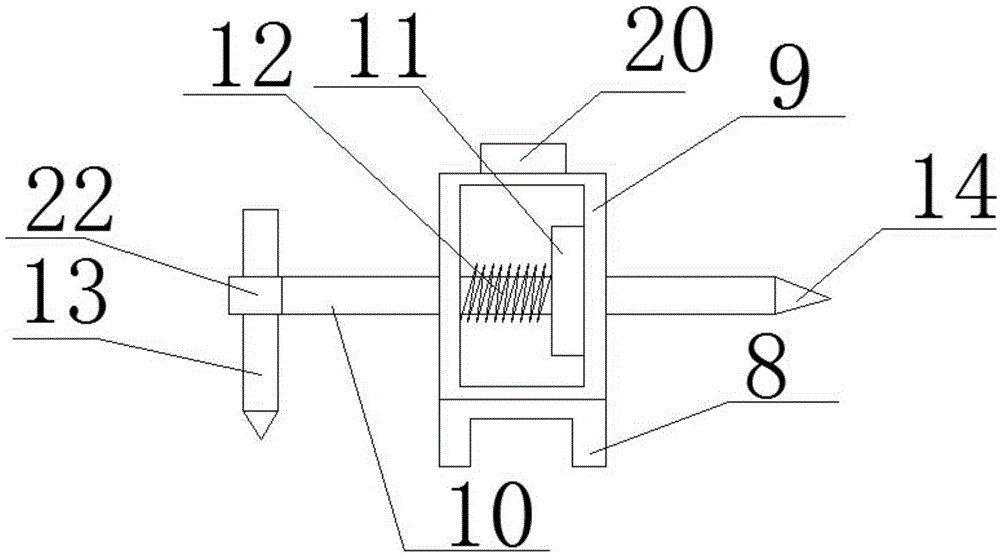

[0015] figure 1 , figure 2 with image 3 A specific embodiment of the present invention is shown: a detection device for the flatness of the side wall of a thin plate, including a workbench 1, on which a parallel first crossbar 2 and a second crossbar 3 are arranged, and the first The cross bar 2 and the second cross bar 3 are respectively provided with slide blocks 4, and the first cross bar 2 and the second cross bar 3 are respectively provided with some threaded holes 5, and the slide blocks 4 are connected with the first cross bar respectively. 2 and the second cross bar 3 are detachably connected by bolts 6, a connecting rod 7 is arranged between the sliders 4, and a movable block 8 is arranged on the connecting rod 7, and the movable block 8 is horizontal on the connecting rod 7 Move, the upper end of described movable block 8 is provided with fixed block 9, and described fixed block 9 is cavity structure, and described fixed block 9 is provided with long rod 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com