Large deflection punch line

A punching line and deflection technology, which is applied in the field of large deflection punching lines, can solve problems such as wasting materials, and achieve the effect of solving waste materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

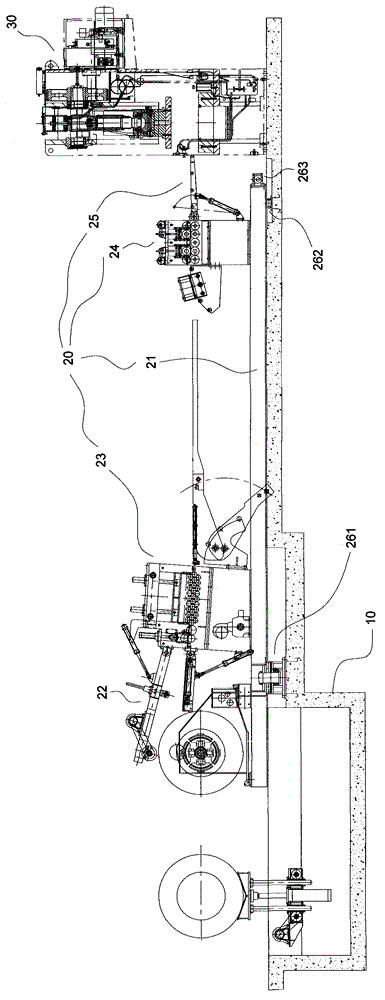

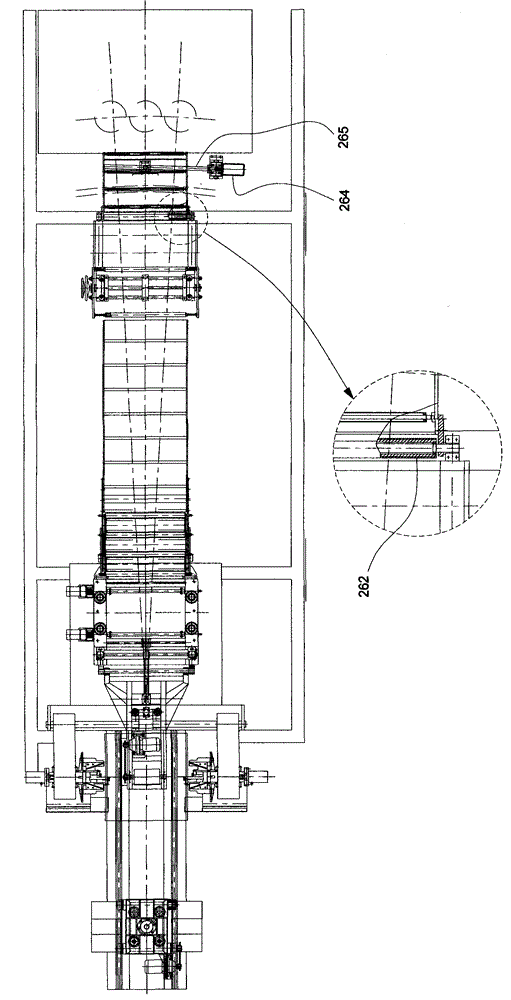

[0010] Such as Figure 1 to Figure 2 Shown is a preferred specific implementation example of the present invention, a large-scale eccentric punching line, including a foundation 10, a material eccentric conveying device 20 and a gantry punch 30, and the material eccentric conveying device 20 can be swingably installed on the On the foundation 10, the gantry punch 30 is fixedly installed on the foundation 10 and corresponds to the material sway conveying device 20, and the material to be stamped is conveyed from the material sway conveying device to the gantry punch 30 for stamping. The pendulum conveying device 20 swings one side of the material corresponding to the stamping position of the gantry punch. After the gantry punch 30 stamps a finished product, the material sway conveying device 20 deflects the unstamped part of the material to the Stamping is carried out at the punching position of the gantry punch 30, and such a cycle causes both sides of the material to correspo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap