Aluminum alloy stamping die for air conditioner shell production

A technology for stamping dies and air conditioner shells, which is used in forming tools, manufacturing tools, metal processing equipment, etc., and can solve the problems of air conditioner shell processing, timely recycling of stamping waste, and impact on stamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

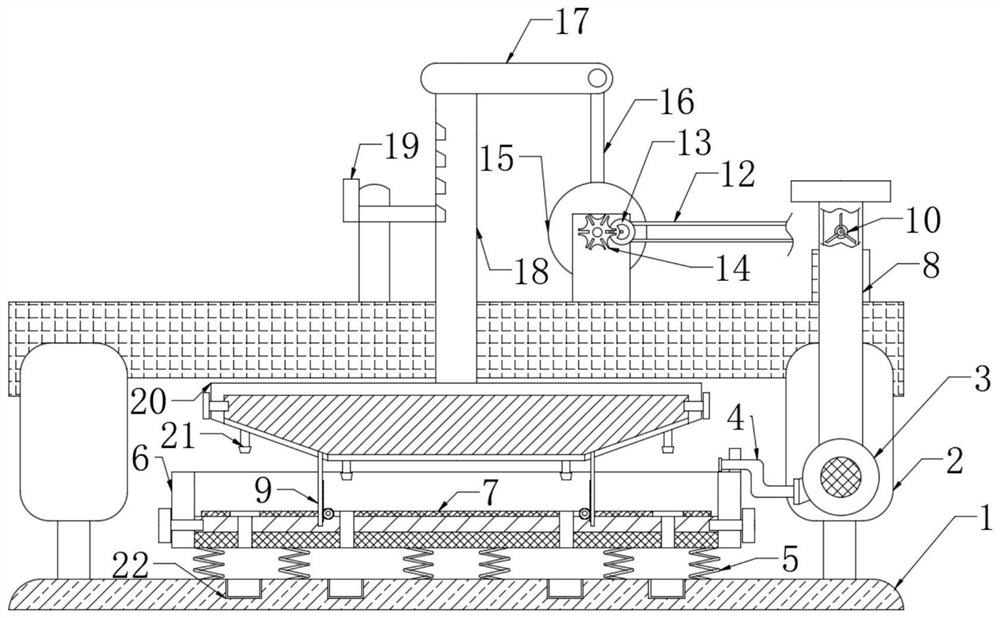

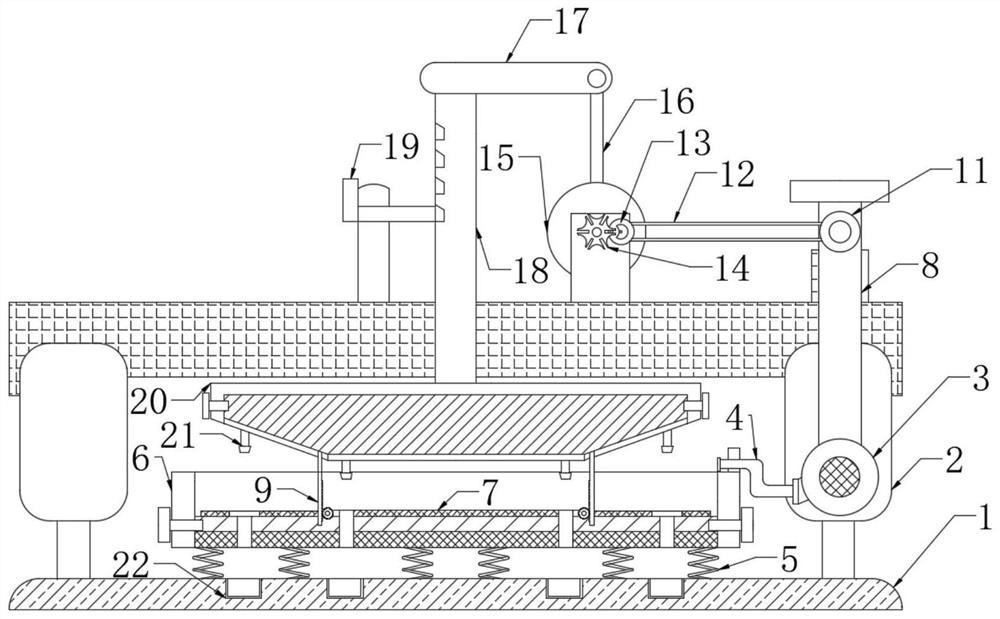

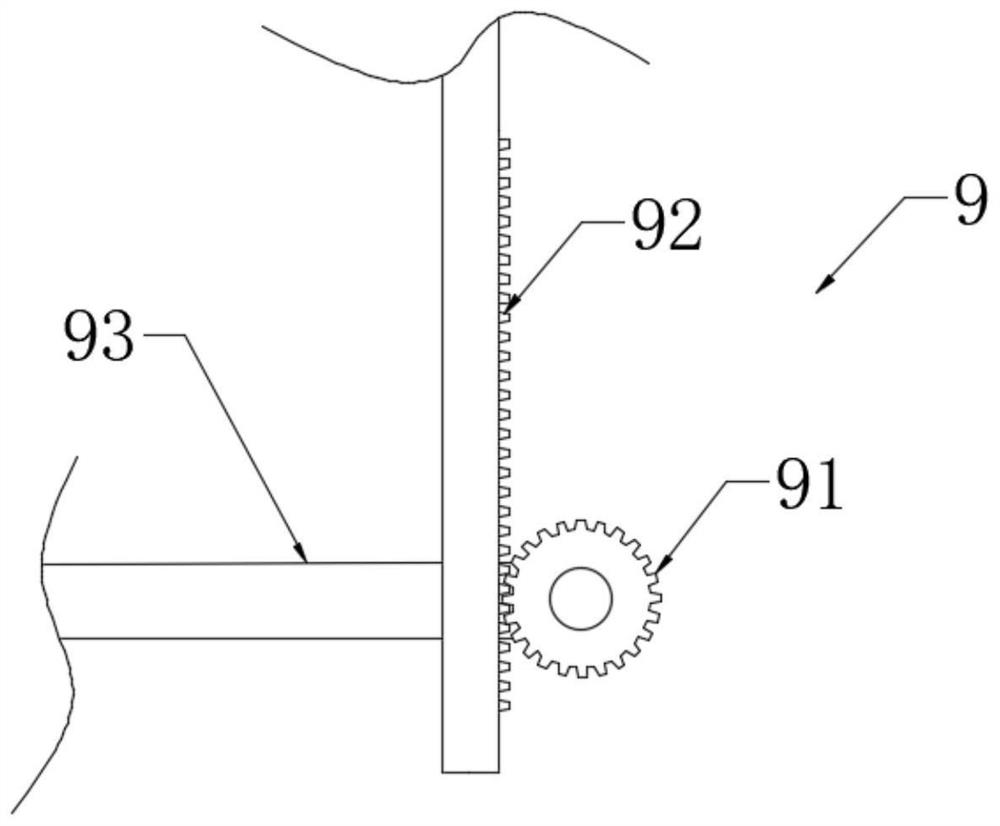

[0025] Such as Figure 1-4 As shown, an aluminum alloy stamping die for the production of an air conditioner casing includes a base 1, a support 2 is provided at both ends of the upper side of the base 1, a support plate is provided at the upper end of the support 2, and an exhaust pipe 8 is fixedly connected to one end of the support plate. 2. A hot air blower 3 is provided at the 8 end of the exhaust pipe. One end of the hot air blower 3 is provided with a hot air pipe 4. The upper end of the hot air blower 3 is fixedly connected with an air exhaust pipe 8. The inner end of the upper side of the air exhaust pipe 8 is rotatably connected with an impeller 10, and the impeller 10 passes through The rotating shaft is coaxially fixedly connected with the belt pulley 11, and the rotating shaft is slidably connected in the thin circular groove. The thin circu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap