A paper-feeding and stamping device and a compensation method for the stamping time of the paper-feeding and stamping device

A compensation method and paper feeding technology, applied in printing, stamping and other directions, can solve the problems of customers' economic loss, the loss of legal effect of stamped documents, and the decline of service quality of financial institutions, so as to avoid trouble and improve service quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

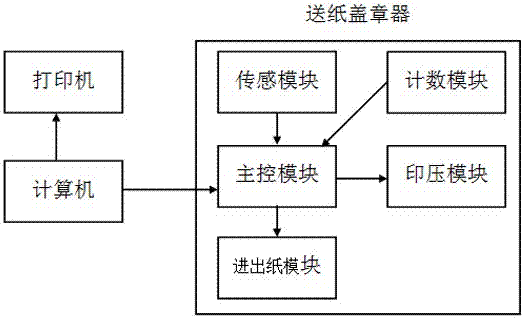

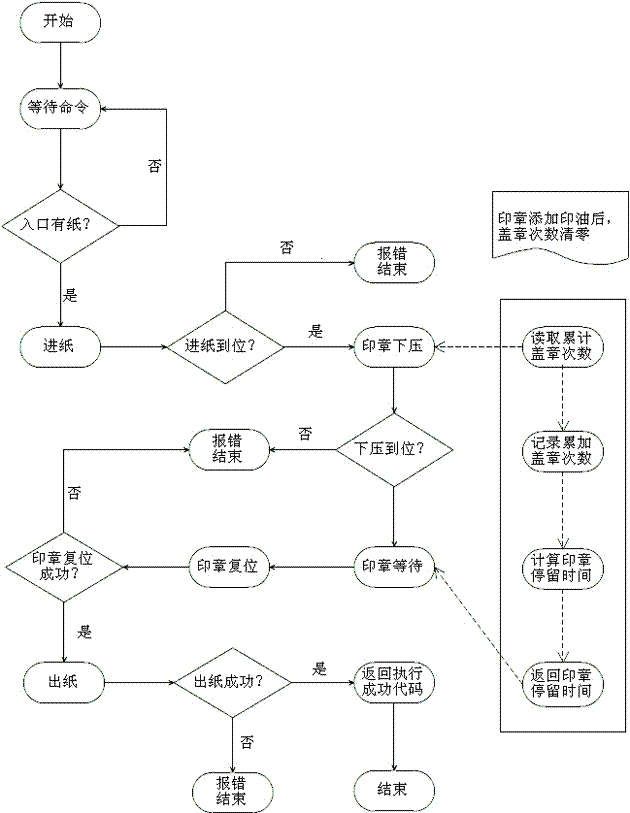

[0013] Such as figure 1 As shown, the paper feeding and stamping device includes a main control module, a sensing module, a paper feeding and outputting module, an embossing module and a counting module. The main control module receives the working signal of the computer and coordinates the operation of other modules. The sensing module adopts an infrared sensor, which is used to detect whether the paper reaches the designated position, and is also used to detect whether the stamp is pressed down and reset accurately. The stamping module is used to drive the stamp to complete the stamping and return. The stamping time is the gap time from when the stamp is put on the paper to when it is taken away from the paper. The counting module is used to record the stamping times of the stamp. The paper input and output module is used to feed in the paper to be stamped and send out the stamped paper to complete the entire automatic stamping operation.

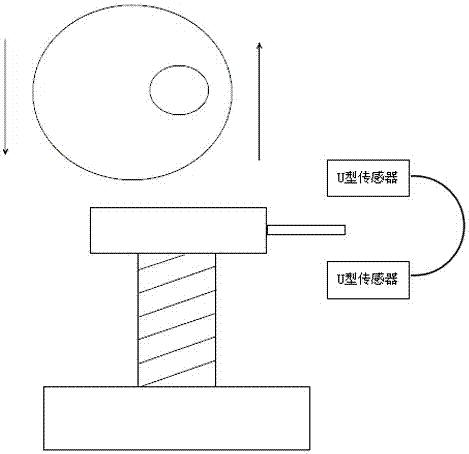

[0014] Such as figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com