Metal painting and making method thereof

A production method and metal painting technology are applied to metal painting. It can solve problems such as rough process, cumbersome process, and inability to achieve industrialized reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing a quadrilateral metal painting, the manufacturing method comprising:

[0031] (1) Pre-processing: Cut the metal plate, and then perform surface treatment on the metal plate. The metal plate includes the screen area in the middle and the frame border area around the screen area. Use a planer to plan the frame border area where the edges need to be folded. Then, cut 90-degree process corners on the four corners of the frame edge area, and finally punch holes in the frame edge area to form reserved holes for installation. Wherein, the surface treatment of the metal plate specifically includes the following steps:

[0032] Grind the cut metal plate to make the surface of the metal plate form any one of mirror surface, wire drawing, and pattern and hairline;

[0033] For coloring, various colors are formed on the surface of the metal plate using precise vacuum titanium plating equipment or water molecule coating equipment technology;

[0034] Ant...

Embodiment 2

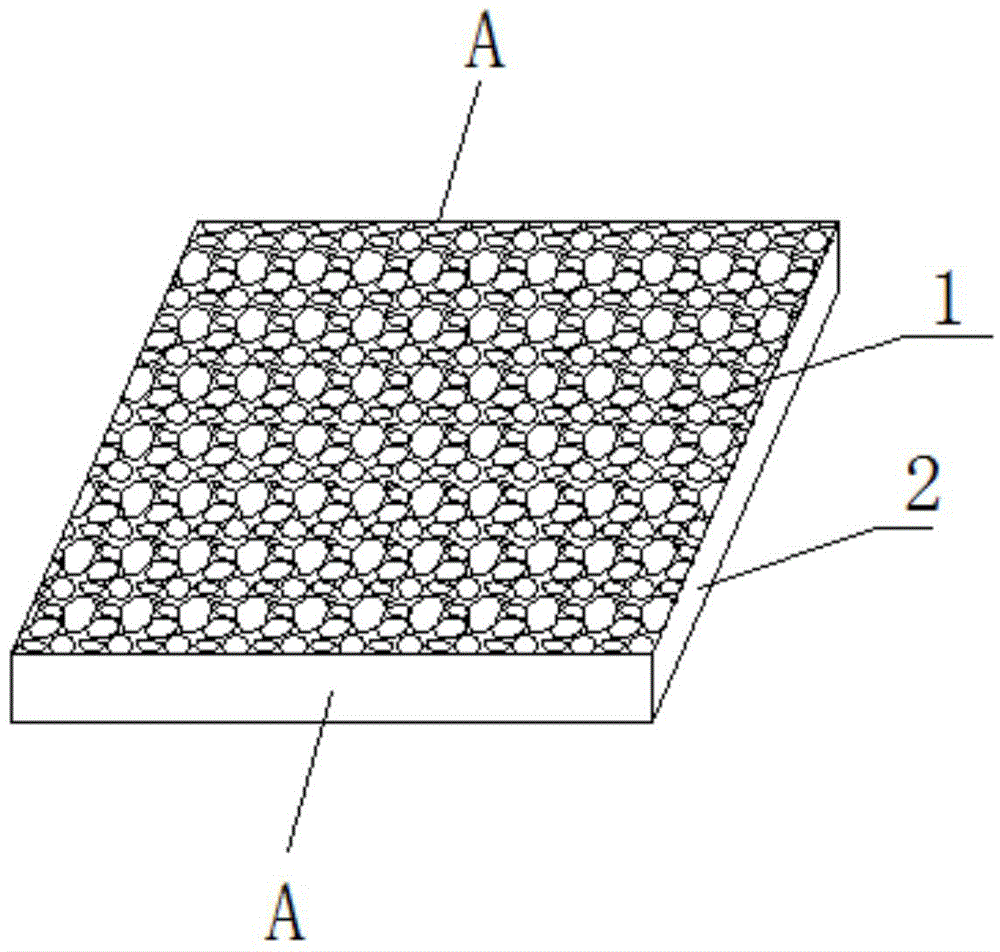

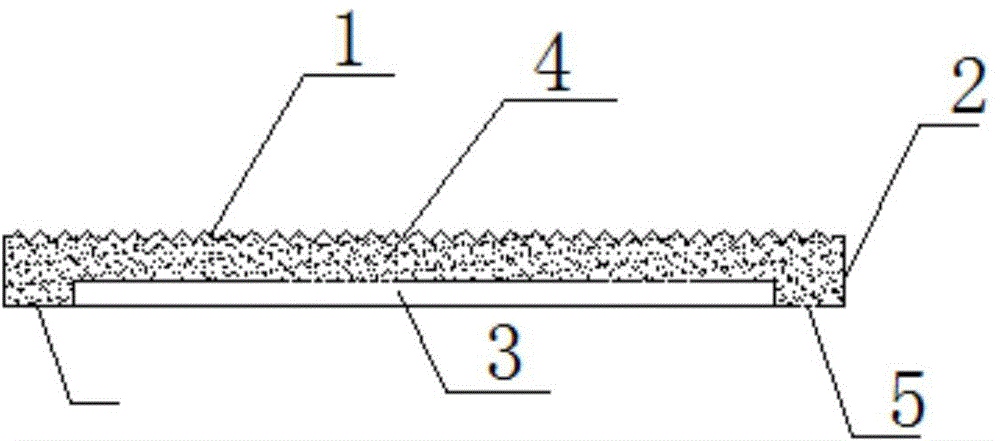

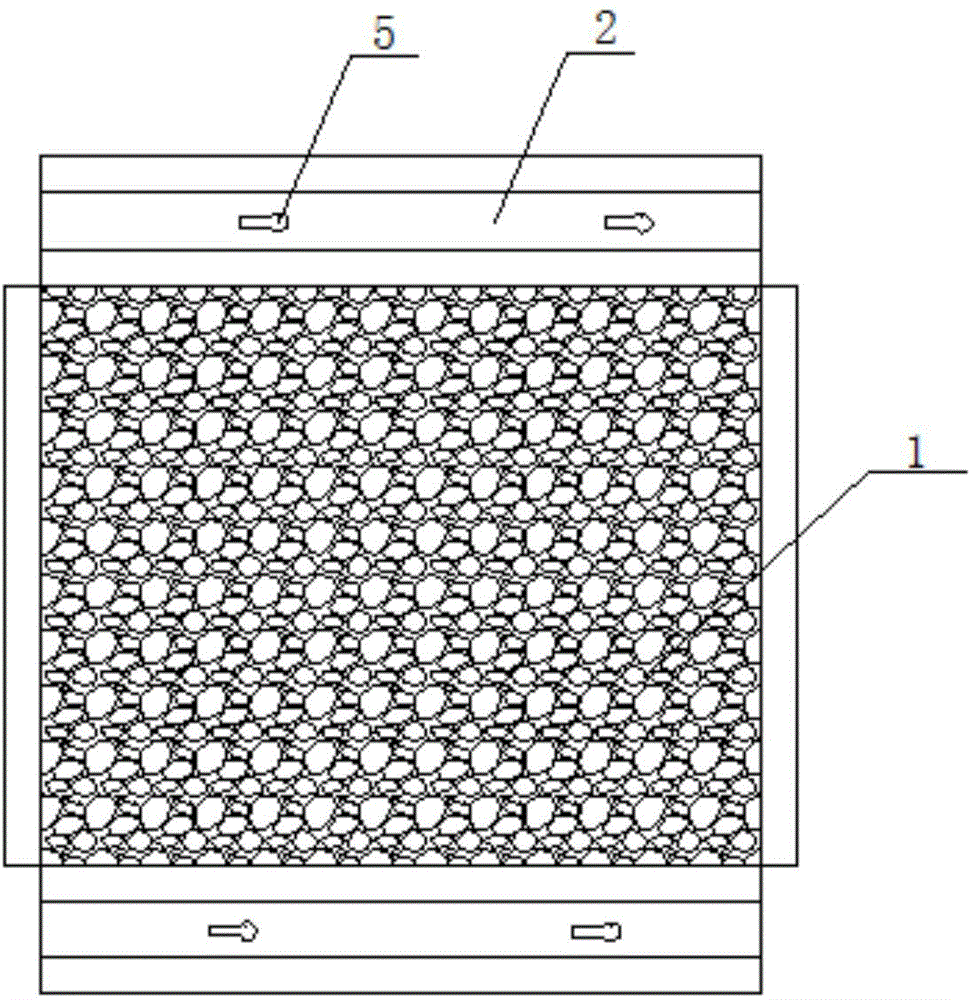

[0040] A quadrilateral metal painting, comprising a metal picture area 1, a metal frame edge 2, and a back plate 3, such as Figure 1-3 As shown, there are concave-convex patterns on the metal screen area 1. The concave-convex patterns are formed by orderly or disorderly arrangement of concave-convex units. These concave-convex patterns can be formed by orderly or disorderly arrangement of concave-convex units. The concave-convex units can be Regular figures, such as circles, triangles, squares, and polygons, can also be irregular figures, such as some twisted folded shapes, or lines. Of course, these concave and convex patterns can also be carved according to the pattern. Such as landscape painting, flower and bird, figure relief and so on. The metal screen area 1 and the metal frame edge 2 are processed by a piece of metal plate, the metal frame edge is formed by bending the metal plate, there is no seam between the metal screen and the metal frame edge, and the metal frame ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap