Brine refining device conducting filtering step by step

A salt water refining and salt water technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of increasing production and operation costs, unqualified salt water quality, etc., and achieves the effects of good application effect, reduced refining cost and high qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

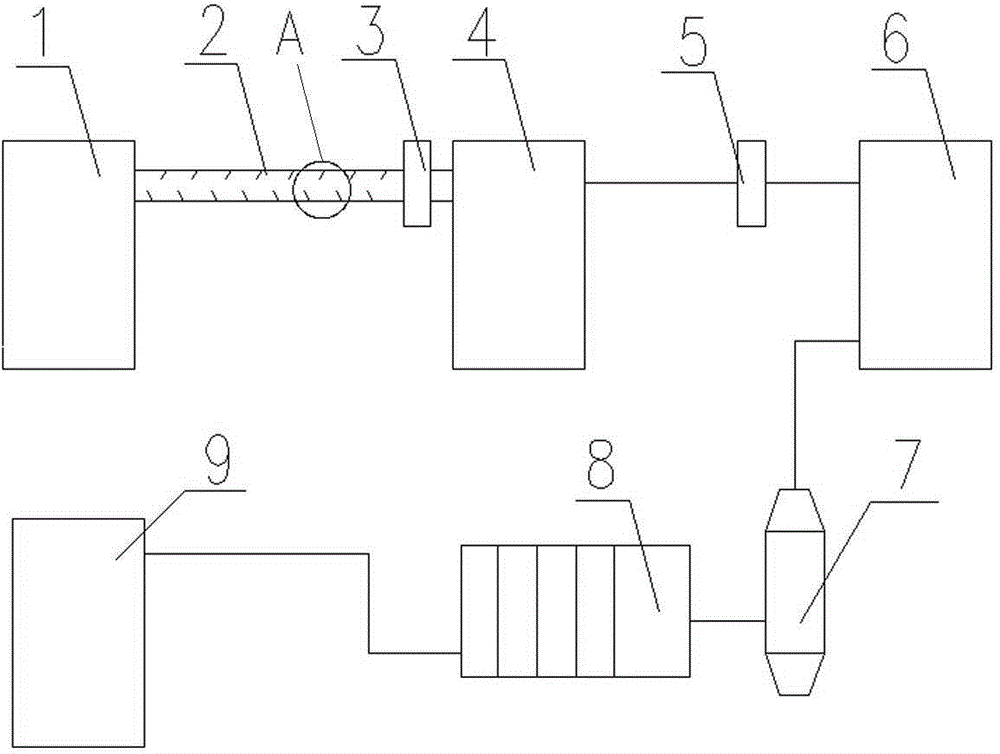

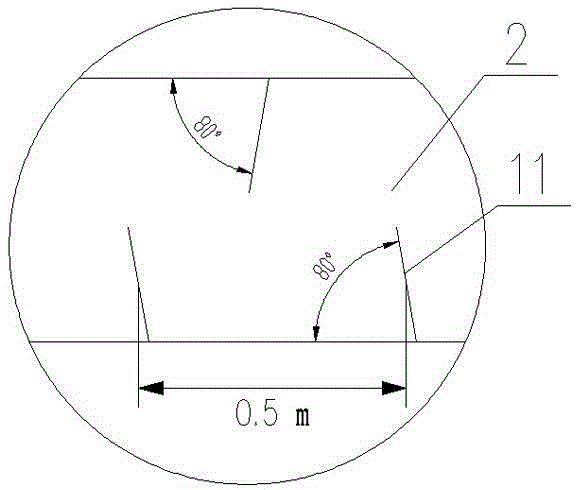

[0017] Attached below figure 1 , attached figure 2 And embodiment further illustrate the present invention.

[0018] A kind of brine refinement device of four-stage step-by-step filtration, see attached figure 1 , attached figure 2 , brine tank 1, brine baffle tank 2, primary brine filter 3, crude brine tank 4, secondary brine filter 5, brine reaction tank 6, third-stage brine filter 7, fourth-stage brine filter 8, Refined brine tank 9, baffle plate 11.

[0019] In this embodiment, the brine barrel 1 is connected to the primary brine filter 3 through the brine baffle tank 2, the primary brine filter 3 is connected to the secondary brine filter 5 through the coarse brine tank 4, and the secondary brine filter 5 The brine reaction barrel 6 is connected to the three-stage brine filter 7, and the three-stage brine filter 7 is connected to the refined brine tank 9 through the four-stage brine filter 8. The first-stage salt water filter 3 has a filter aperture of 3 cm; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com