Dual vibrators with pulleys, screed and pavers

A pulley, paver technology, applied in the field of double vibrating mechanism, screed and paver, can solve the problems of reduced maximum torque and power, increased cost, increased overall size of double vibrating mechanism, etc. Maximum alternating stress, effect of improving resistance to fatigue loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

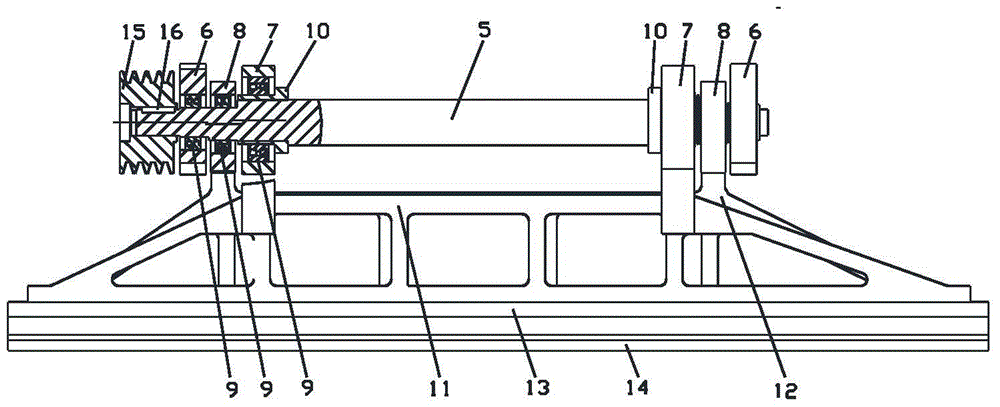

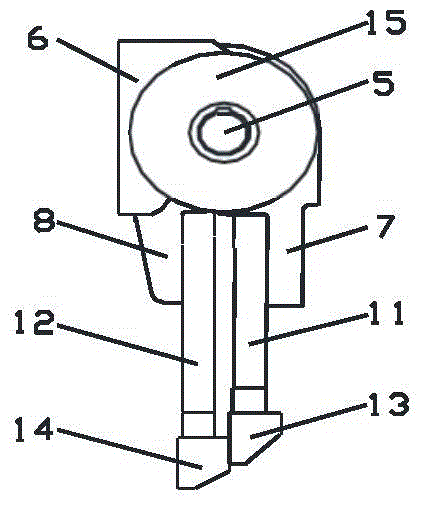

[0028] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

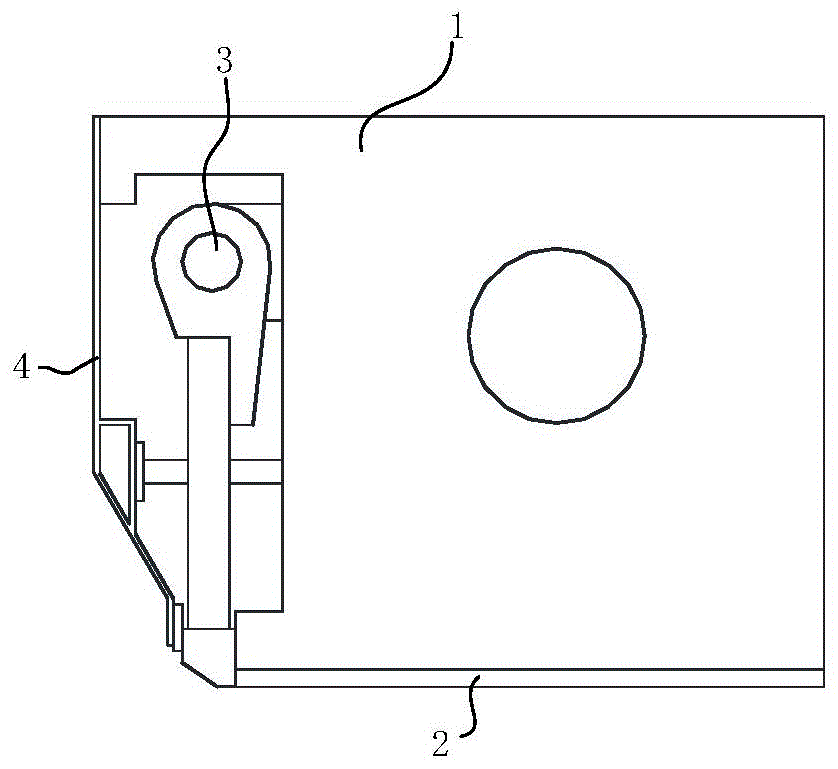

[0029] Such as figure 2 with image 3 As shown, the double vibrating mechanism with pulleys provided by the present invention is used for compacting paving materials, including a vibrating shaft 5, a vibrating bearing seat, a vibrating blade, a fixed bearing seat 6 and a pulley 15; Figure 4 Show the structural representation of the vibrating shaft of the dual vibrating mechanism with pulleys of the present invention, as Figure 4 As shown, the vibrating shaft 5 is symmetrically provided with a fixed bearing seat installation section 51 near both ends, and the fixed bearing seat 6 is arranged on the fixed bearing seat installation section 51; the vibrating shaft 5 is also provided with There is a vibrating bearing seat installation section for installing the vibrating bearing seat, and the vibrating blade is connected with the vibrating be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com