A hinged conversion type externally prestressed concrete tower and its construction method

A technology of external prestressing and concrete, which is applied in the direction of towers, special data processing applications, building types, etc., and can solve the cracking of ordinary prestressed concrete towers, uneven stress distribution, material costs and transportation costs of external prestressed concrete towers Problems such as high hoisting costs on the project site can achieve the effect of improving the quality and reliability of project construction, simplifying the construction process, and reducing the difficulty of construction implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

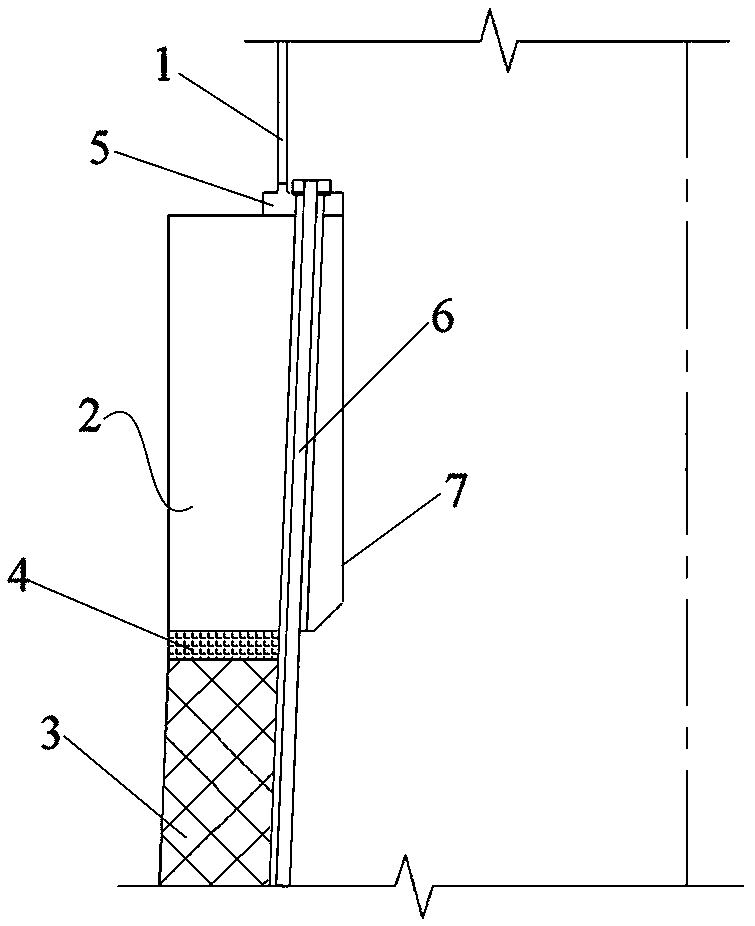

[0034] Example as figure 1 Shown:

[0035] A hinged conversion type external prestressed concrete tower, comprising an ordinary prestressed concrete tower 3 and an external prestressed beam 6 arranged close to its inner wall surface, and a prestressed anchorage area is set on the upper end surface of the ordinary prestressed concrete tower 3 Ring beam 2, a steel tower 1 is set on the upper surface of the ring beam 2 in the prestressed anchorage area; a torsional deformation buffer support 4 is arranged between the ring beam 2 in the prestressed anchorage area and the ordinary prestressed concrete tower 3, and the torsion-resistant The deformation buffer bearings 4 are evenly and closely arranged in the circular section at the upper end of the ordinary prestressed concrete tower 3, and the anti-torsion deformation buffer bearings 4 are flat rubber bearings or spherical hinge steel bearings, or other pressure-bearing and The bearing that releases the rotation constraint, the fl...

Embodiment 2

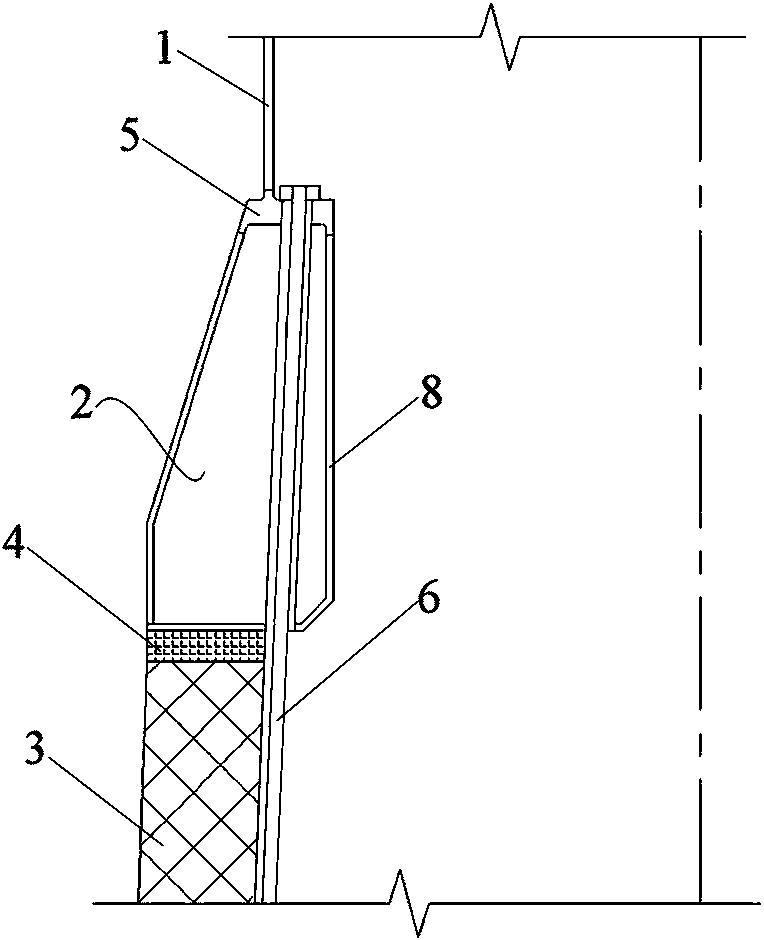

[0036] Example two such as figure 2 Shown:

[0037] The difference between Embodiment 2 and Embodiment 1 is that the ring beam 2 in the prestressed anchorage area is a ring-shaped special-shaped steel box girder 8, and the longitudinal section of the ring-shaped special-shaped steel box girder 8 is a structure with a narrow top and a wide bottom, and the width of its lower end surface is Not less than the width of the upper end surface of the ordinary prestressed concrete tower 3 , the ring beam 2 in the prestressed anchorage area is fixed to the steel tower 1 by welding the flange 5 fixed at the bottom of the steel tower 1 .

Embodiment 3

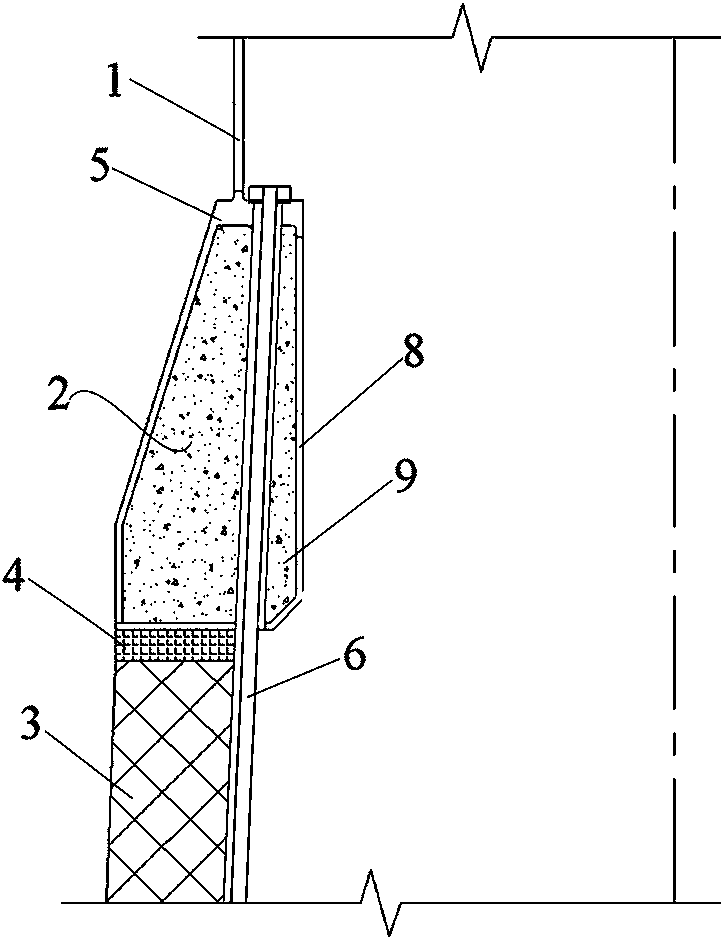

[0038] Embodiment three such as image 3 Shown:

[0039] The difference between the third embodiment and the second embodiment is that: the steel box girder 8 is filled with concrete 9 inside the ring-shaped special-shaped steel box girder.

[0040] The present invention also includes the construction method of the above-mentioned hinged conversion type external prestressed concrete tower, which is characterized in that it includes the following steps:

[0041] Step 1. Carry out the overall finite element numerical simulation calculation: according to the preliminarily selected prestressed anchorage area ring beam 2 section and the preliminarily selected spherical hinge steel support to establish the overall combination of external prestressed concrete and steel tower 1) wind power tower model, and input the load conditions of the wind power tower, and carry out the overall finite element numerical simulation calculation;

[0042] Step 2. Determine the specifications of each p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com