A three-dimensional braided composite material prosthesis and its preparation method

A composite material and three-dimensional weaving technology, applied in prostheses, artificial legs, medical science, etc., can solve problems such as unsatisfactory mechanical properties of prosthetics, weak bonding force, short service life, etc., to improve the overall mechanical properties and fatigue load resistance performance, improved environmental durability, and improved strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

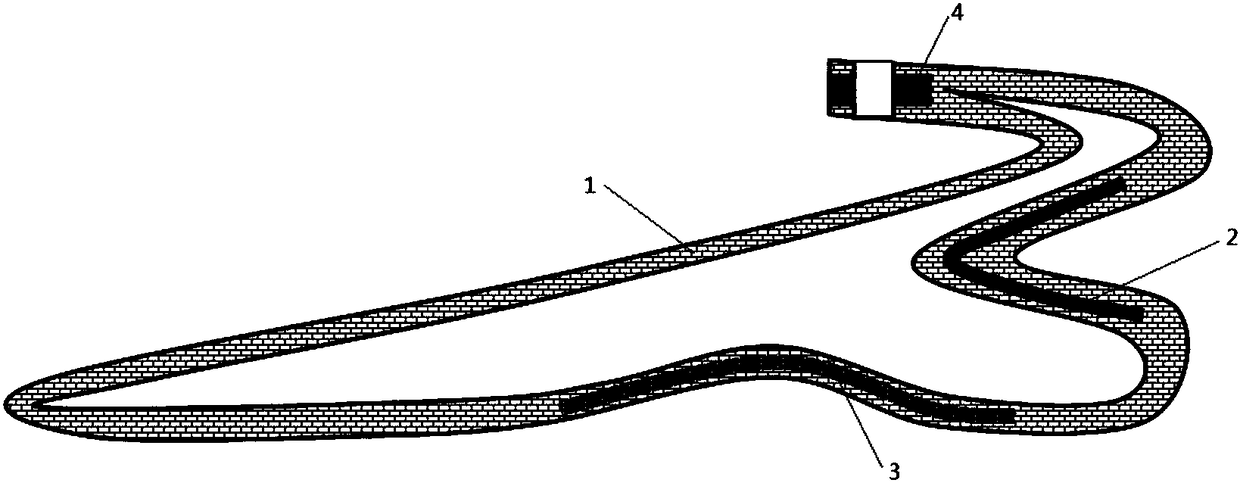

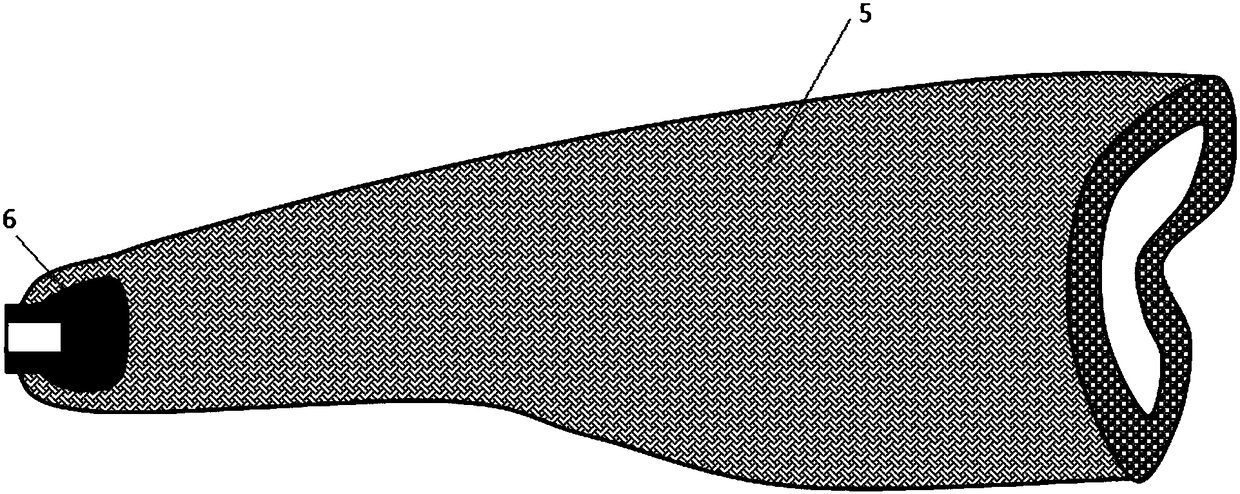

[0035] A three-dimensional braided composite prosthesis, including a three-dimensional braided composite foot prosthesis 1 and a three-dimensional braided composite calf prosthesis 5;

[0036] Such as figure 1 As shown, the three-dimensional braided composite foot prosthesis 1 is a three-dimensional braided preform of the foot prosthesis made of high-strength fibers and high-toughness fibers, and is laid along the thickness direction of the three-dimensional braided preform of the foot prosthesis. The structure formed by seams and composed of seam fibers and thermosetting resin are compositely molded; the foot prosthesis is hollow inside and has a foot structure of toe, sole, heel and ankle, wherein the three-dimensional The three-dimensional braided preform is provided with a two-dimensional laminated fabric molded composite material reinforcement 3, and the three-dimensional three-dimensional braided preform at the heel is provided with a first metal reinforcement 2, and the...

Embodiment 2

[0044] The invention relates to a foot and leg prosthesis prepared by using a three-dimensional fiber fabric reinforced resin-based composite material. The preparation method is as follows. First, the fabrication of three-dimensional braided composite foot prostheses. The foot prosthesis components adopt the integrated molding technology of three-dimensional weaving of fiber fabrics, imitating the structure of the foot and adopting a hollow structure, and using T700 carbon fiber and aramid fiber as the raw material for the filament fiber preparation of the three-dimensional fabric. The mixture of carbon fiber and aramid fiber The proportion is 1:1, and the main body design of the foot prosthesis is made of a three-dimensional five-way fabric structure, in which a composite structure embedded with metal reinforcements is used in the heel, and the three-dimensional fabric in this part adopts a three-dimensional five-way structure; The two-dimensional laminated fabric molded comp...

Embodiment 3

[0050] The invention relates to a foot and leg prosthesis prepared by using a three-dimensional fiber fabric reinforced resin-based composite material. The preparation method is as follows. First, the fabrication of three-dimensional braided composite foot prostheses. The prosthetic component of the foot adopts the integrated molding technology of three-dimensional weaving of fiber fabrics. It adopts a hollow structure imitating the structure of the foot, and uses the mixture of T800 carbon fiber and aramid fiber as the filament fiber raw material for three-dimensional fabric preparation. The mixture of carbon fiber and aramid fiber The proportion is 1:1, and the main body design of the foot prosthesis is made of a three-dimensional four-way fabric structure, in which a composite structure with embedded metal reinforcements is used at the heel, and the three-dimensional fabric at this part adopts a three-dimensional six-way structure; The two-dimensional laminated fabric molde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com