Motor graders and scarifiers

A technology for rippers and graders, which is applied to earth movers/shovels, construction, etc., which can solve the problems of limited blade movement space, large resistance to loosening soil, and accelerated wear of loosening rake teeth, so as to ensure the passing performance , reduce loose soil resistance, reduce the effect of oil consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

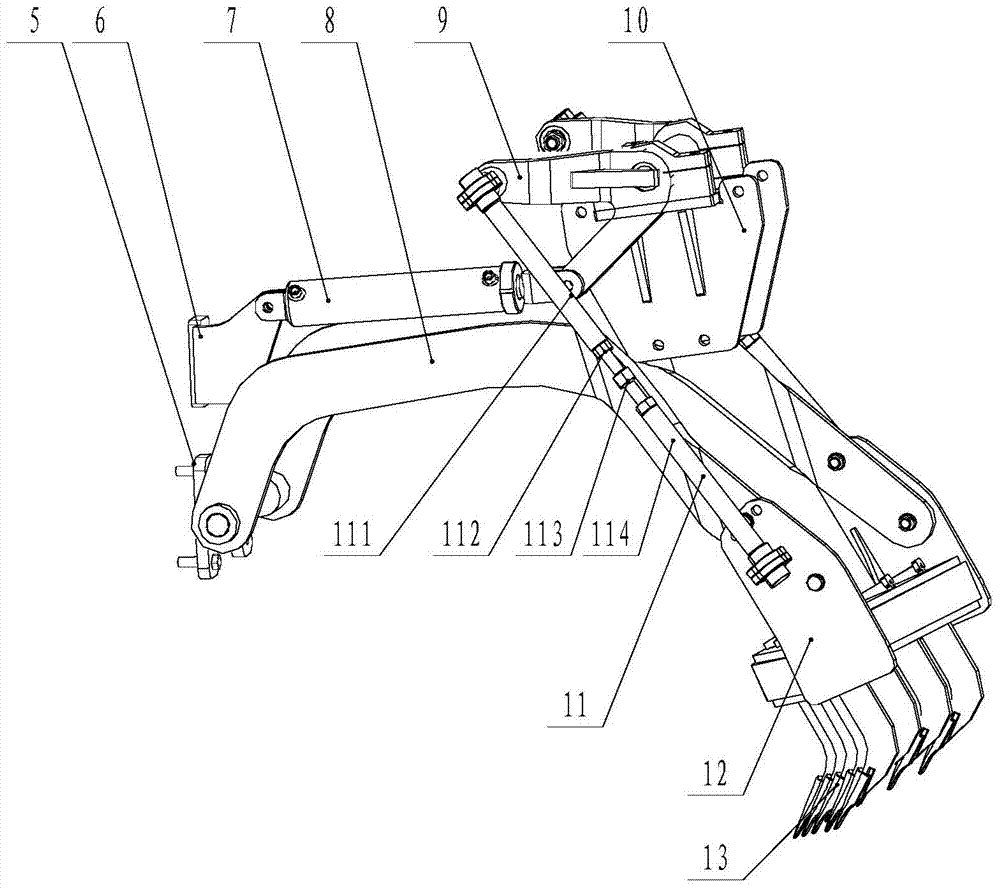

[0026] Embodiment one: if figure 1 As shown, the scarifier 1 comprises a rocker support 10, the top of the rocker support 10 is hinged with a rocker 9, and the bottom of the rocker support 10 is fixedly connected with the loosening support 12, and the bottom of the loosening support 12 is provided with a loosening arm. Rake teeth 13, support arms 8 are respectively provided on both sides of the soil loosening support 12;

[0027] The two ends of described rocking arm 9 are fixedly connected with oil cylinder 7 and an end of pull rod 11 respectively, and the other end of oil cylinder 7 is fixedly connected with oil cylinder holder 6, and the other end of pull rod 11 is fixedly connected with loose soil support 12, and oil cylinder 7 can pass through The rocker arm 9 drives the pull rod 11 and the soil loosening bracket 12 to move, so as to realize the adjustment of the height of the soil loosening rake teeth 13;

[0028] Described soil loosening support 12 is provided with low...

Embodiment 2

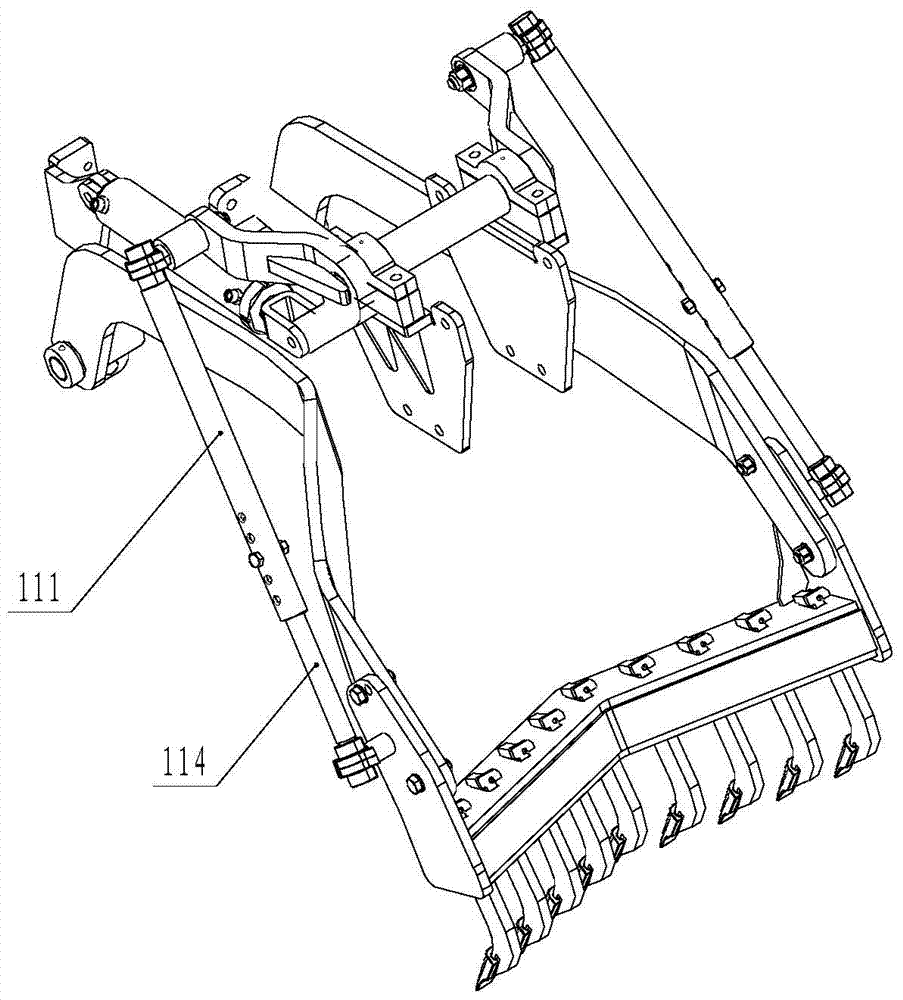

[0030] Embodiment two: if figure 2 As shown, the pull rod 11 includes an upper pull rod 111, the upper pull rod 111 is provided with a lower rod 114, the upper pull rod 111 and the lower rod 114 are provided with more than one positioning hole, and the positioning hole is provided with a positioning bolt; One is the same.

Embodiment 3

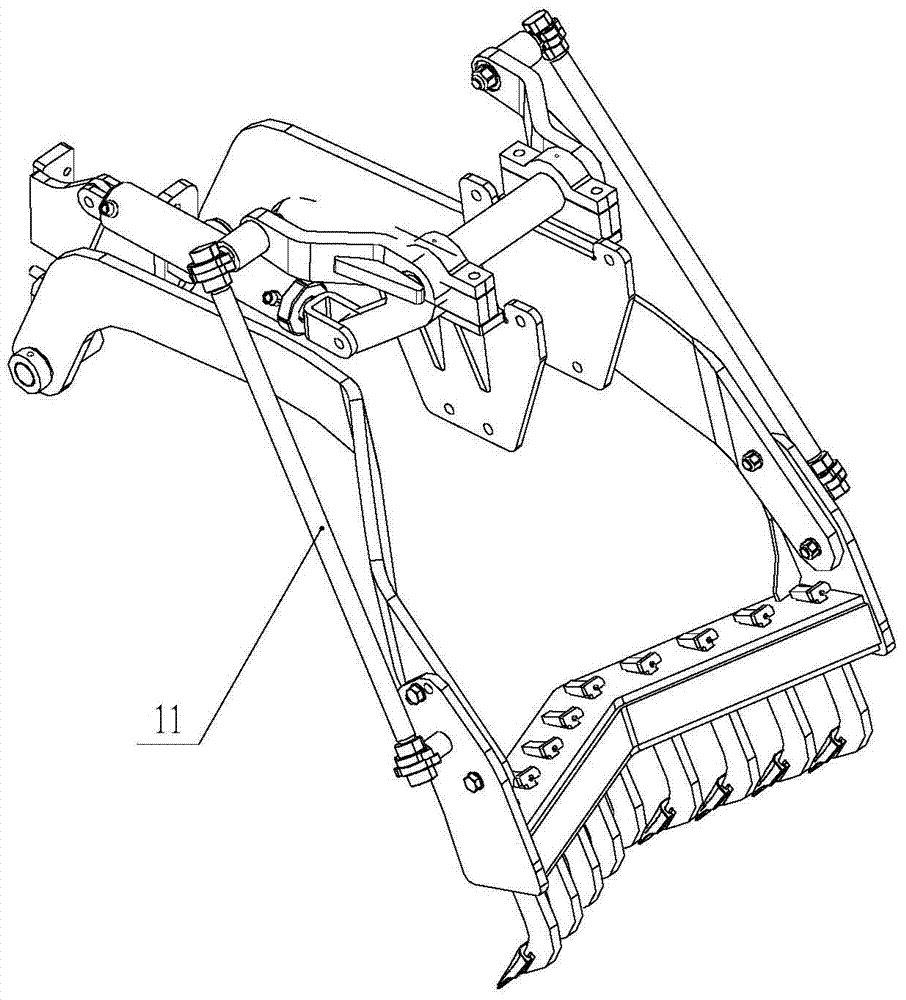

[0031] Embodiment three: as image 3 As shown, the pull rod 11 is a whole with a fixed length; the others are the same as the first embodiment.

[0032] Such as figure 1 As shown, the grader includes the aforementioned ripper 1 , and the ripper 1 is arranged between the front axle 4 of the grader and the blade working device 3 .

[0033] When the present invention is installed, the supporting arm fixing seat 5 is installed on the supporting arm 8, and the ripper 1 is connected with the front frame 2 of the motor grader through the supporting arm fixing seat 5 and the oil cylinder fixing seat 6; the oil cylinder 7 can be placed as a single oil cylinder according to specific conditions. On one side of the front frame 2 of the grader, it can also be placed on both sides of the front frame 2 of the grader for double oil cylinders.

[0034] Such as figure 1 with Figure 4 As shown, when the motor grader encounters a working condition with a large cutting depth, and the adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com