Cage component of single-row roller bearing and cage component installation method

A roller bearing and cage technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor cage lubrication, easy wear of the cage, inconvenient installation of rollers, etc. High degree and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

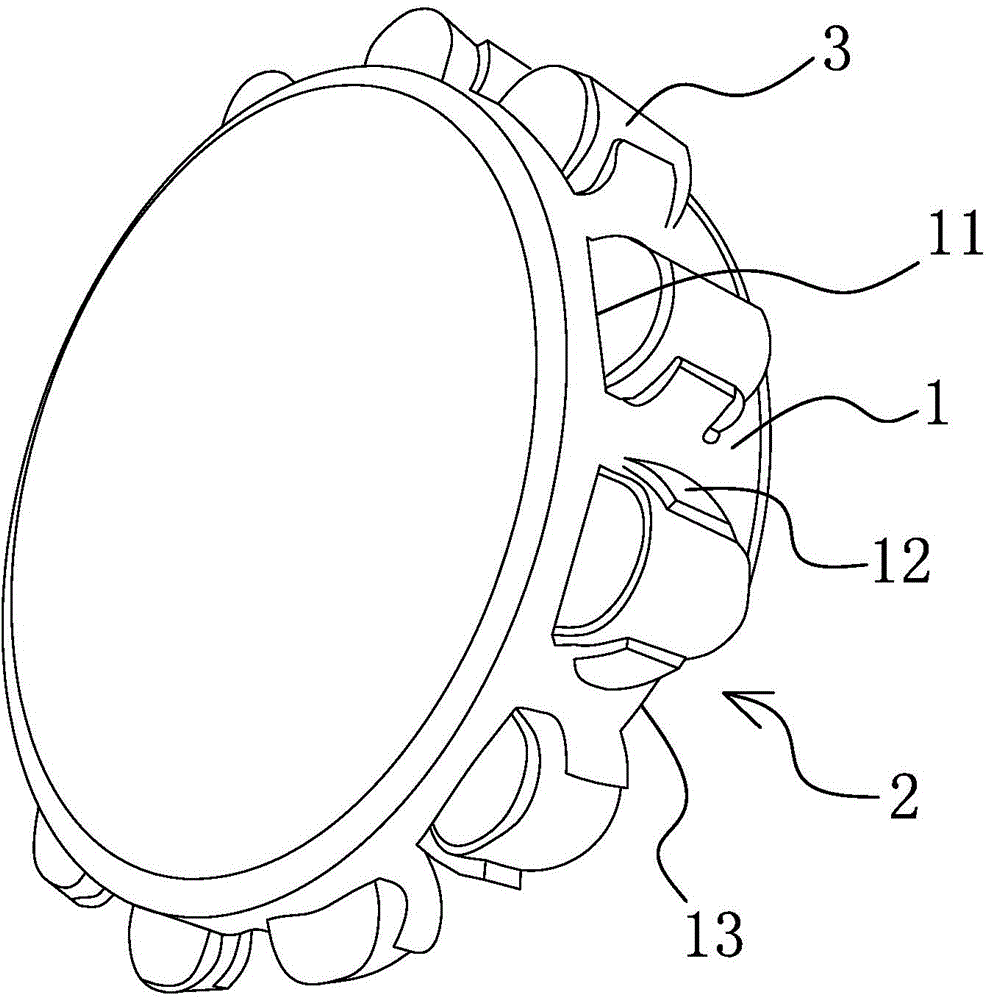

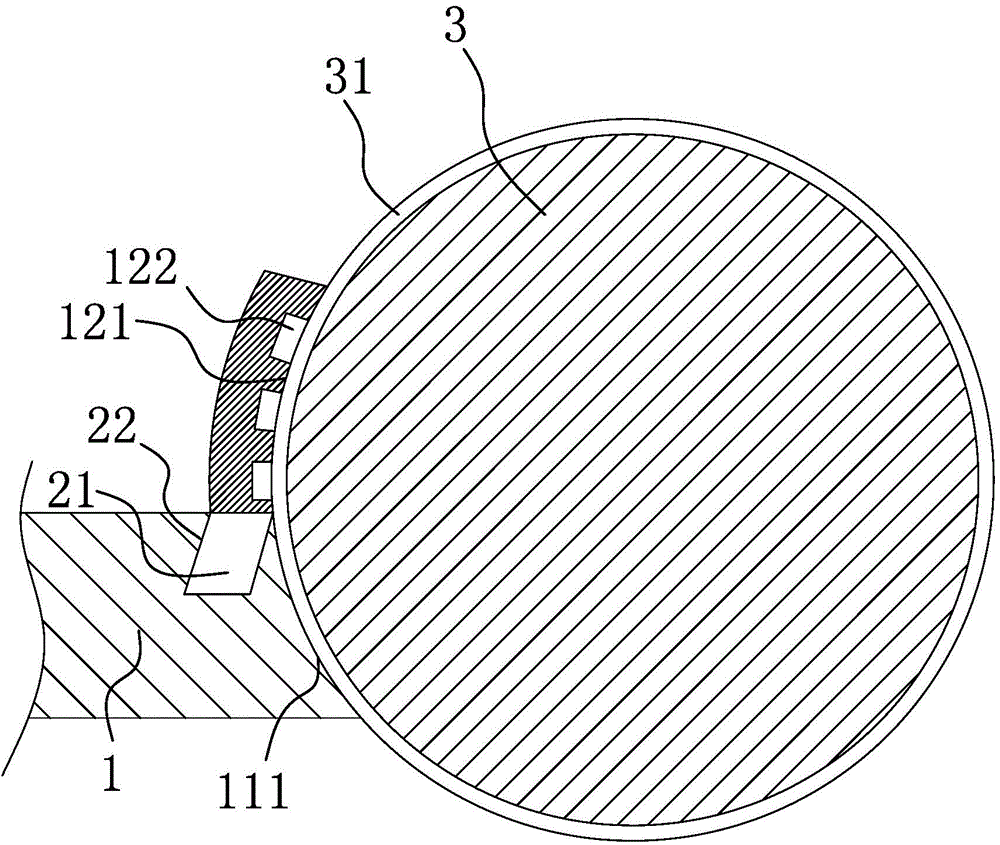

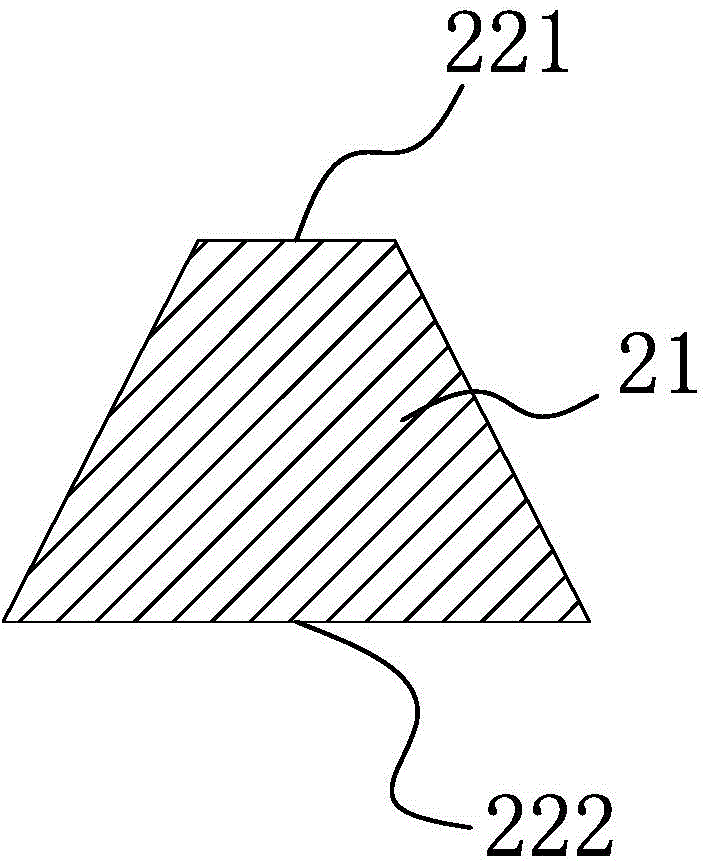

[0023] Such as Figure 1-4 As shown, the cage assembly of the single row roller bearing includes a cylindrical cage body 1, and the cage body 1 has a plurality of strip-shaped holding holes 11 extending axially along the cage body 1 in the circumferential direction. The hole 11 is provided with a roller body 3 that can rotate in the circumferential direction. The width of the strip-shaped holding hole 11 is gradually reduced from the outside of the cage body 1 to the inside. The arc-shaped inclined surface 111 of the sub-body 3 is in contact with the outside, and the outer sides of the bar-shaped holding hole 11 are respectively provided with limit bars 12. Arbuting against the arc-shaped retaining surface 121, and the arc-shaped retaining surface 121 has several strip-shaped oil grooves 122 extending along the width direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com